Secondary reforming equipment

An equipment, a technology for reforming gas, applied in combustion equipment, lighting and heating equipment, combustion methods, etc., can solve problems such as unsatisfactory refractory materials, short life of oxygen feed pipes, etc., to reduce the number of shutdowns, The effect of long operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

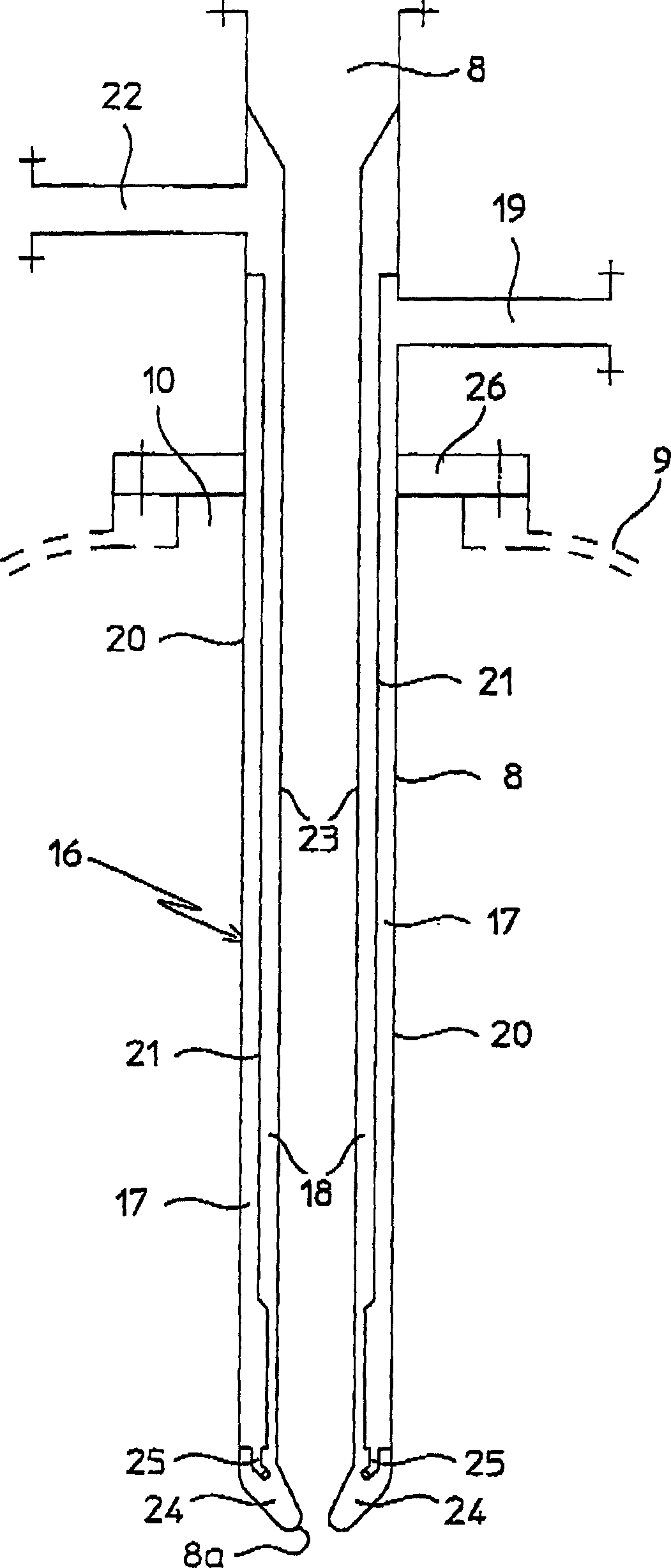

[0026] refer to figure 1 , numeral 1 generally designates a secondary reformer of this type comprising a substantially cylindrical housing 2, in which is placed a catalytic bed 3 carrying out a secondary reaction, such as a steam reforming reaction, to produce synthesis gas.

[0027] At the top end of the casing 2 , generally frusto-conical, a combustion chamber 4 is defined for burning hydrocarbons, and at the lower end of the casing 2 , a compartment 5 is defined for collecting the synthesis gas produced in the catalytic bed 3 . The combustion chamber 4 and the compartment 5 are in fluid communication with said catalytic bed 3 .

[0028] Above the conical portion delimiting the combustion chamber 4, the casing 2 ends with an upper cylindrical appendage 2a of smaller diameter, which is the casing of the vertical duct 7 feeding reformed gases (hydrocarbons) to the combustion chamber 4 . Inside the conduit 7, a vertical tubular oxygen feed pipe 8 is installed, coaxial with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com