Secondary lithium cell using aminobenzene-benzoquinone composite polymer as cathode materal and prepn. thereof

A composite polymer and secondary lithium battery technology, which is applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as difficult to reach the molecular level and inconspicuous advantages, achieve low cost, improve internal conductivity, and improve the synthesis process non-polluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Synthesis of poly-1-aminoanthraquinone cathode material

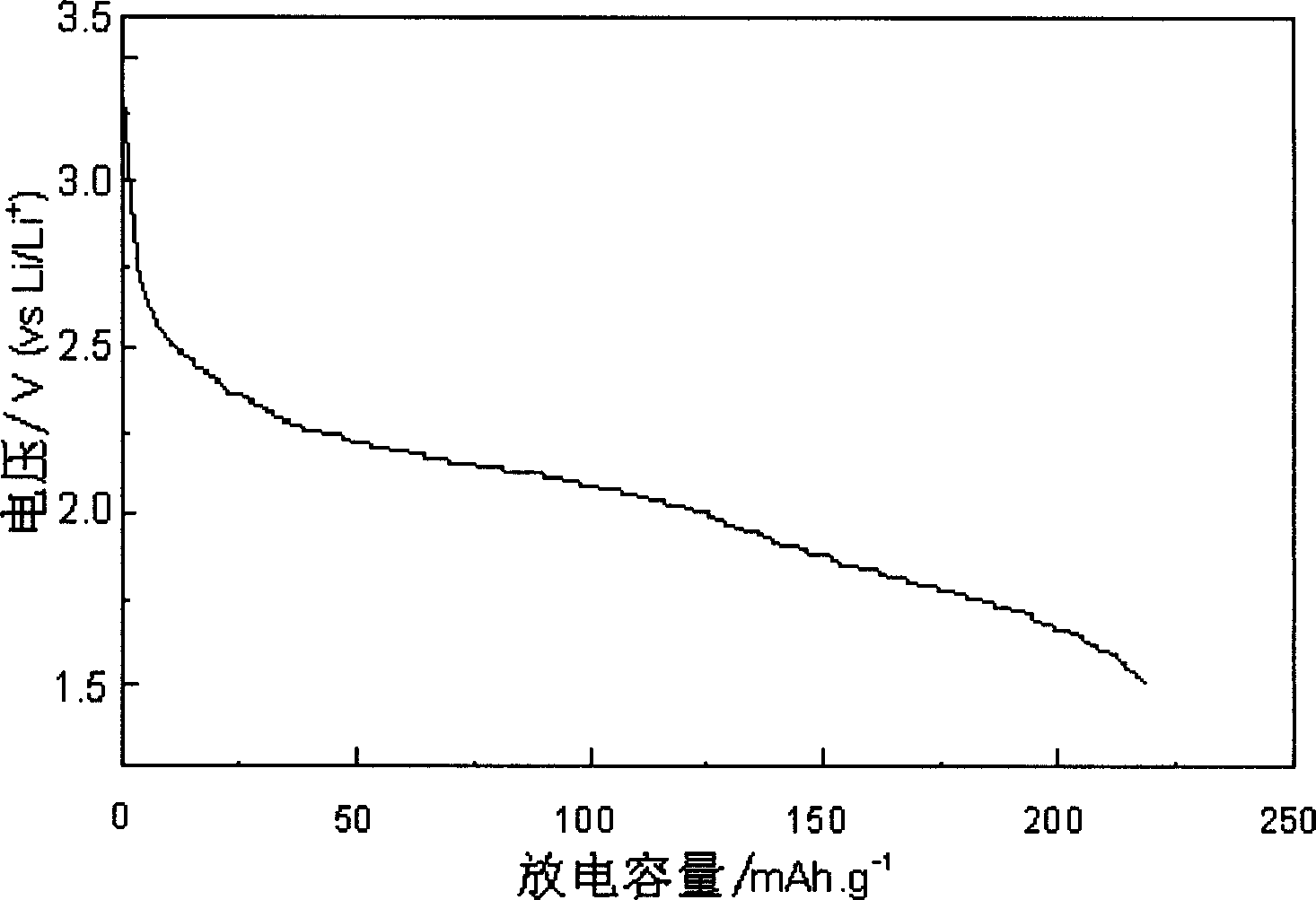

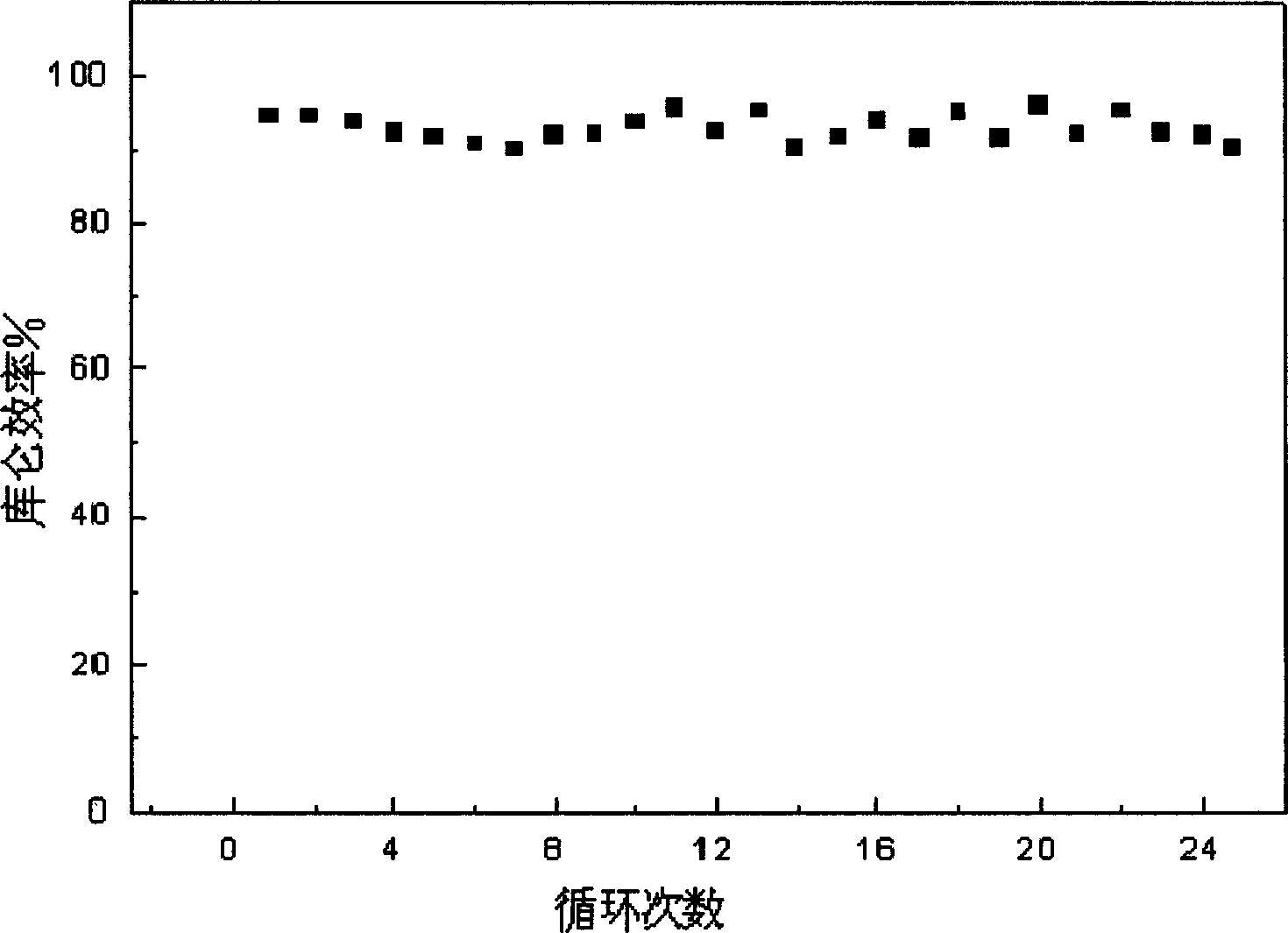

[0030] Weigh 1.435g of 70% HClO 4 Aqueous solution, 2.280g (NH 4 ) 2 S 2 o 8 , 1.133g concentration of 30% H 2 o 2 Saturated aqueous solution and 2.230g of 1-aminoanthraquinone, mixed the above materials in acetonitrile, reacted for 24h under the protection of argon and magnetic stirring, controlled the reaction temperature at 0°C, and washed the obtained product with acetonitrile and deionized water in sequence after the reaction The brown-black precipitate was air-dried at 60°C for 2 hours and vacuum-dried at 80°C for 12 hours to obtain the poly-1-aminoanthraquinone cathode material.

[0031] 2. Cathode Fabrication

[0032] Weigh poly-1-aminoanthraquinone, acetylene black and polytetrafluoroethylene (60% aqueous emulsion) according to 70:20:10 mass percentage, mix the above-mentioned substances in ethanol dispersant, and put them on the tablet machine after ultrasonic and stirring Press the aluminum ...

Embodiment 2

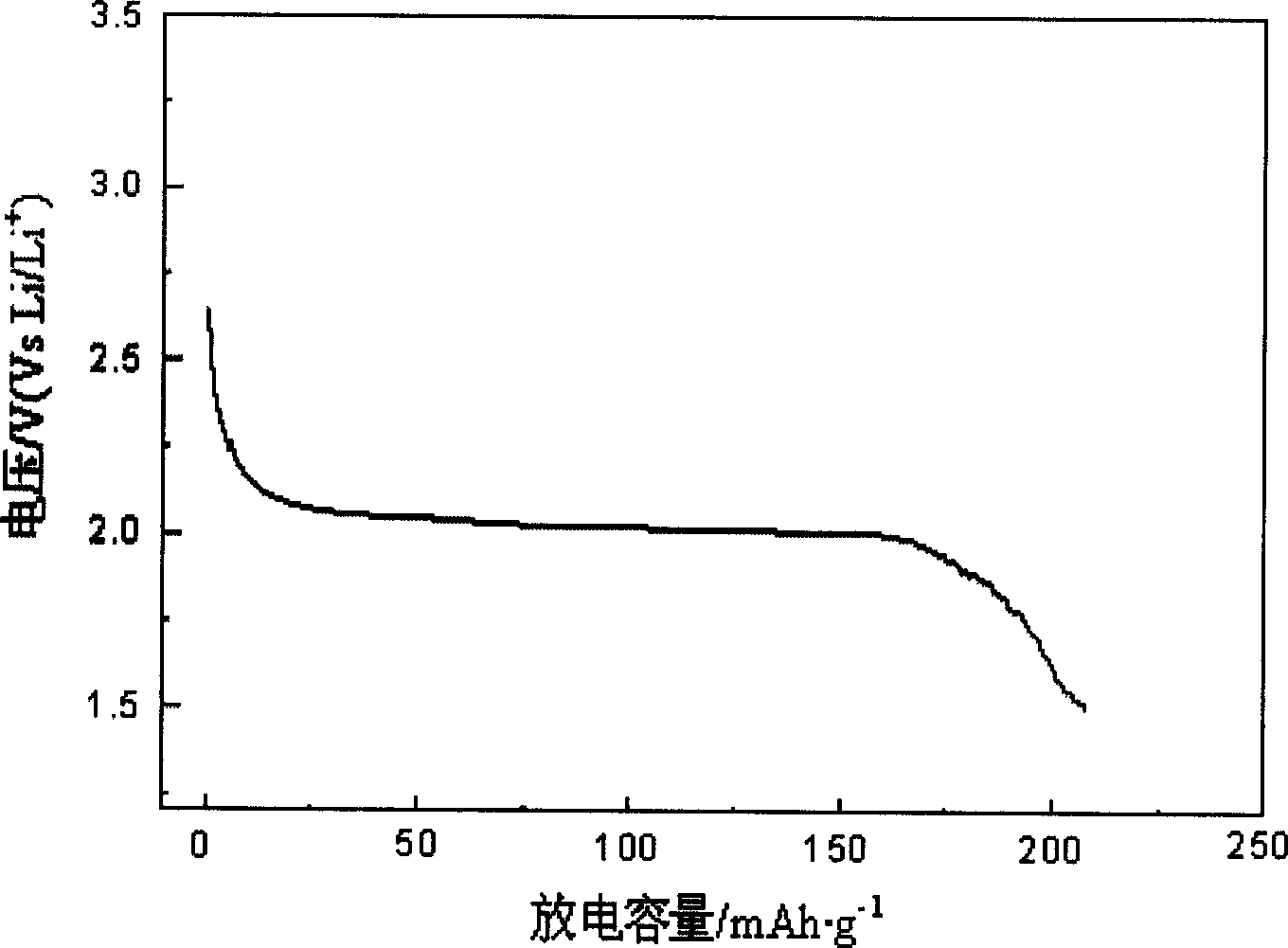

[0036] 1. Synthesis of poly-1,5-di-aminoanthraquinone cathode material

[0037] In this example, 1.190 g of 1,5-diaminoanthraquinone was selected as the composite polymer monomer, and the synthesis process of the polymer and the dosage of other components were the same as in Example 1.

[0038] 2. Cathode fabrication and battery testing

[0039] The cathode manufacturing process and battery test conditions are the same as in Example 1. Experiments have proved that the first discharge capacity of poly 1,5-diaminoanthraquinone cathode material reaches 210.3mAh g -1 , after 30 charge-discharge cycles, it can still maintain more than 75% of the initial discharge capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com