Process of preparaing methyl acrylate by waste organic glass and apparatus thereof

A technology of methyl methacrylate and plexiglass, which is applied in the field of recycling waste plexiglass, which can solve the problems of complex continuous pyrolysis process equipment, difficulty in mastering process production, and high operation requirements, achieving large production capacity and eliminating procedures , equipment and process parameters advanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

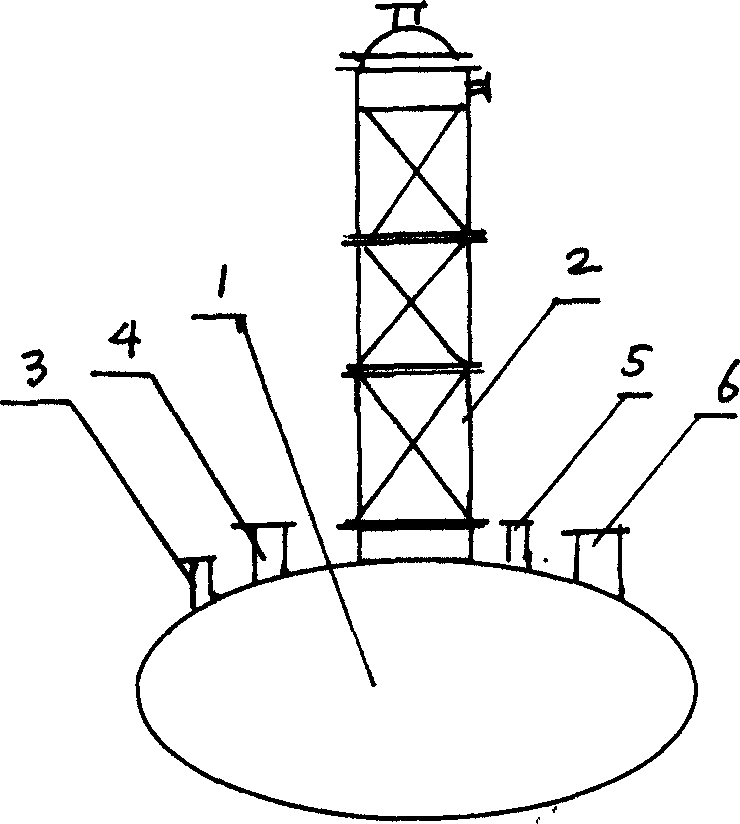

[0032] Refer to attached figure 1 , 2 Shown, the present invention is semi-continuous cracking method and cracking and distillation integration device, and this device is to be provided with distillation tower 2 on cracking still 1, and efficient packing is built in tower, and tower top is provided with condenser 21, cooler 22, Dehydrator 23; the bottom of the cracking tank described in the present invention is oblate, circular, or disc-shaped, and oblate-spherical. The pyrolysis tank bottom of this shape can ensure that the ratio of the heating area to the amount of the pyrolysis material reaches as large a ratio as possible. The cracking kettle is also provided with a cracking post-stage vacuum extraction condensation collection system, and the vacuum extraction condensation collection system is composed of a vacuum pump 54, a buffer 53, a storage tank 52, a condenser 51, etc., and the cracking kettle 1 is connected to the condenser 51. The outlet of the condenser is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com