Process for preparing orientation arrangement zinc sulfide and zinc oxide nano cable composite material

A zinc oxide nanometer and directional alignment technology, which is applied in the direction of zinc sulfide, nanostructure manufacturing, cable/conductor manufacturing, etc., can solve the problems of low activity and difficult application, and achieve the effects of low reaction temperature, low pollution and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

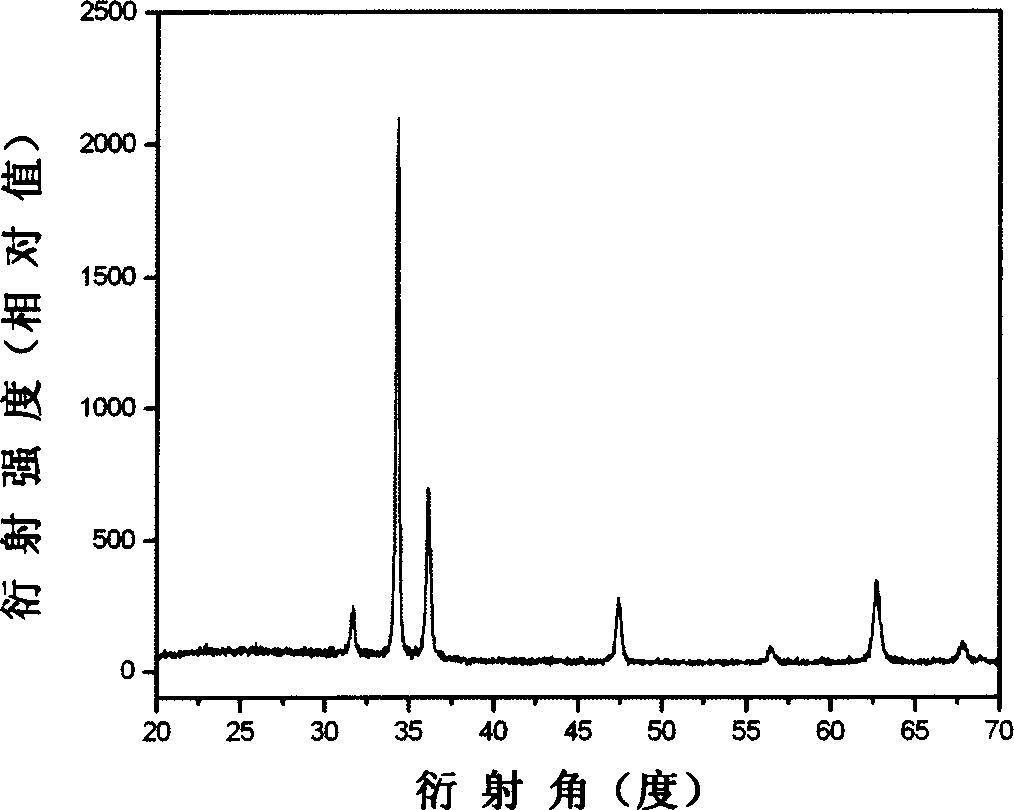

[0028] ①Preparation of zinc oxide nanomaterials with aligned nanorods:

[0029] a) Preparation of chemical growth reaction solution: dissolve zinc nitrate hexahydrate, thiourea, ammonia water and ammonium chloride in deionized water in a certain proportion to prepare a film growth reaction solution, containing 0.01mol of zinc nitrate hexahydrate in every 100ml aqueous solution , 25% (mass ratio) ammoniacal liquor 5ml, thiourea 0.01mol and ammonium chloride 0.002mol;

[0030] b) pretreatment of the substrate: at first the quartz substrate was immersed in boiling 98% concentrated sulfuric acid for 10 hours, then immersed in acetone and ultrasonicated for 60 minutes, then rinsed with a large amount of deionized water, and finally the substrate was placed in the Dry in a vacuum oven until ready to use.

[0031] c) Synthesis of zinc oxide nanomaterials with aligned nanorods: before the reaction, first soak the substrate into the chemical growth reaction solution prepared above; then...

Embodiment 2

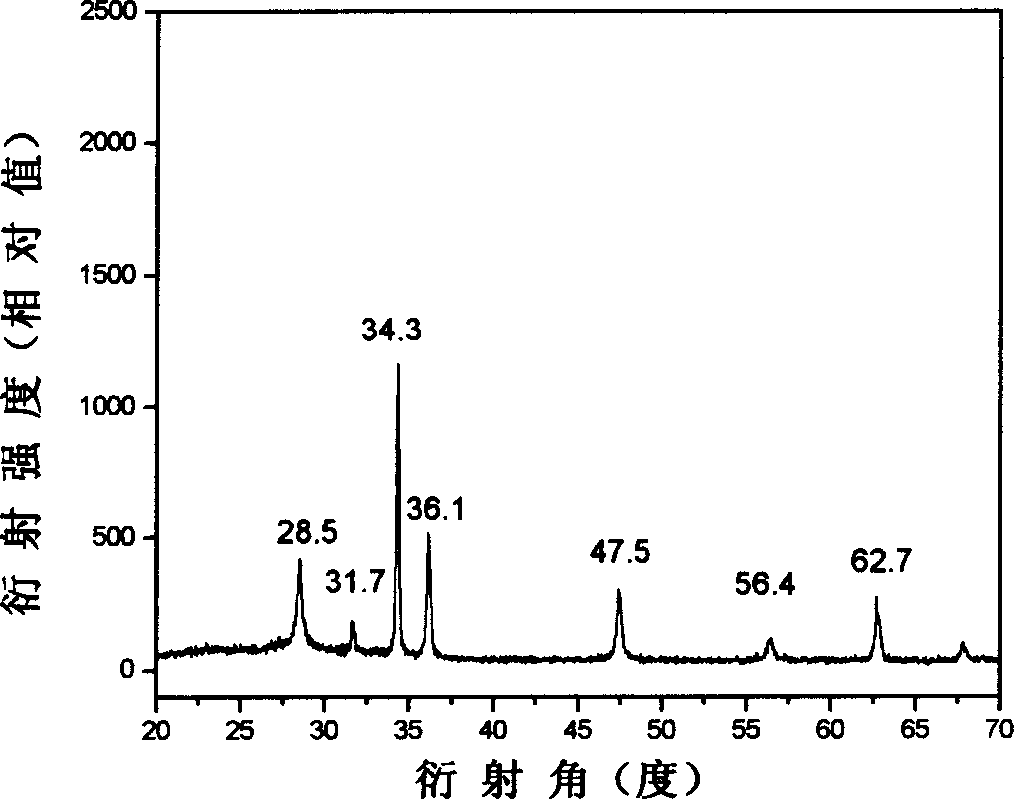

[0037] ① Preparation of ZnO nanomaterials with aligned nanorods:

[0038] a) Preparation of chemical growth reaction solution: dissolve zinc nitrate hexahydrate, thiourea, ammonia water and ammonium chloride in deionized water in a certain proportion to prepare a film growth reaction solution, containing 0.01mol of zinc nitrate hexahydrate in every 100ml aqueous solution , 25% (mass ratio) ammoniacal liquor 5ml, thiourea 0.01mol and ammonium chloride 0.002mol;

[0039] b) pretreatment of the substrate: at first the quartz substrate was immersed in boiling 98% concentrated sulfuric acid for 10 hours, then immersed in acetone and ultrasonicated for 60 minutes, then rinsed with a large amount of deionized water, and finally the substrate was placed in the Dry in a vacuum oven until ready to use.

[0040] c) Synthesis of zinc oxide nanomaterials with aligned nanorods: before the reaction, first soak the substrate into the chemical growth reaction solution prepared above; then rai...

Embodiment 3

[0045] ① Preparation of ZnO nanomaterials with aligned nanorods:

[0046] a) Preparation of chemical growth reaction solution: dissolve zinc nitrate hexahydrate, thiourea, ammonia water and ammonium chloride in deionized water in a certain proportion to prepare a film growth reaction solution, containing 0.01mol of zinc nitrate hexahydrate in every 100ml aqueous solution , 25% (mass ratio) ammoniacal liquor 5ml, thiourea 0.01mol and ammonium chloride 0.002mol;

[0047] b) pretreatment of the substrate: at first the quartz substrate was immersed in boiling 98% concentrated sulfuric acid for 10 hours, then immersed in acetone and ultrasonicated for 60 minutes, then rinsed with a large amount of deionized water, and finally the substrate was placed in the Dry in a vacuum oven until ready to use.

[0048] c) Synthesis of zinc oxide nanomaterials with aligned nanorods: before the reaction, first soak the substrate into the chemical growth reaction solution prepared above; then rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com