Adulterating method used for adulterating vertical pulling silicon mono crystal and its adulterating funnel

A technology of Czochralski silicon single crystal and funnel, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of difficult crystal growth, complicated high-concentration uniform doping technology, etc. The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

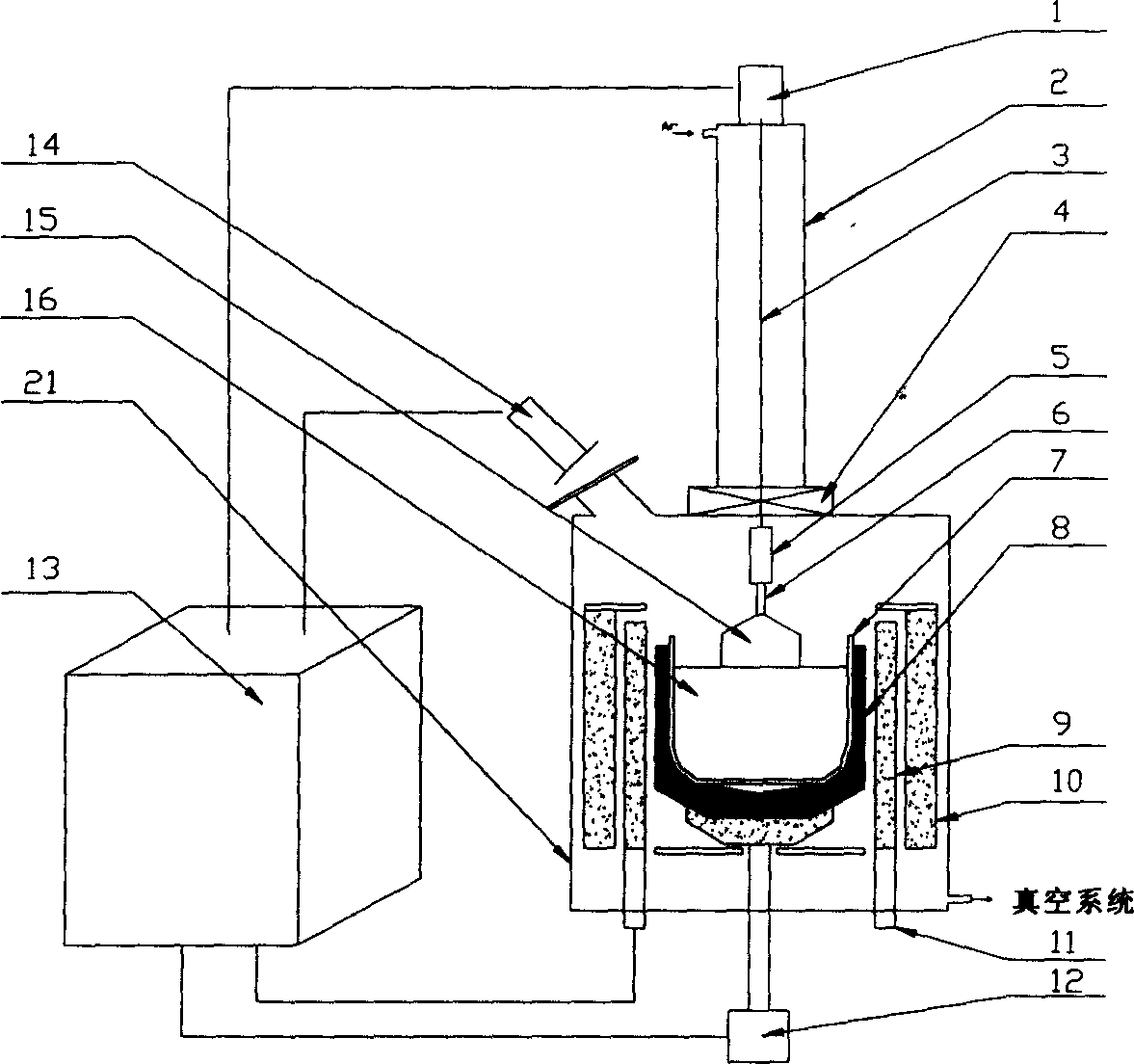

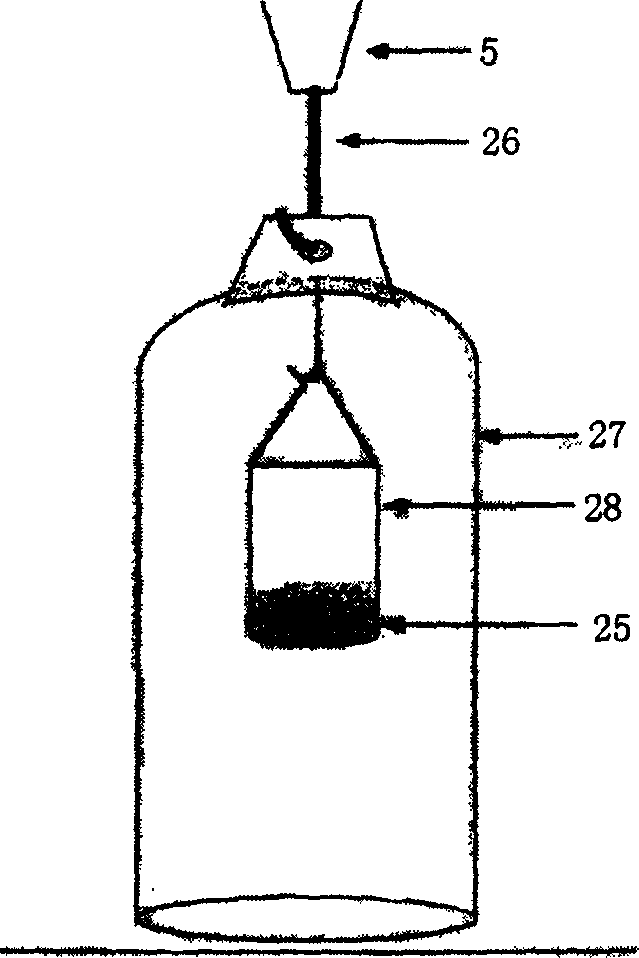

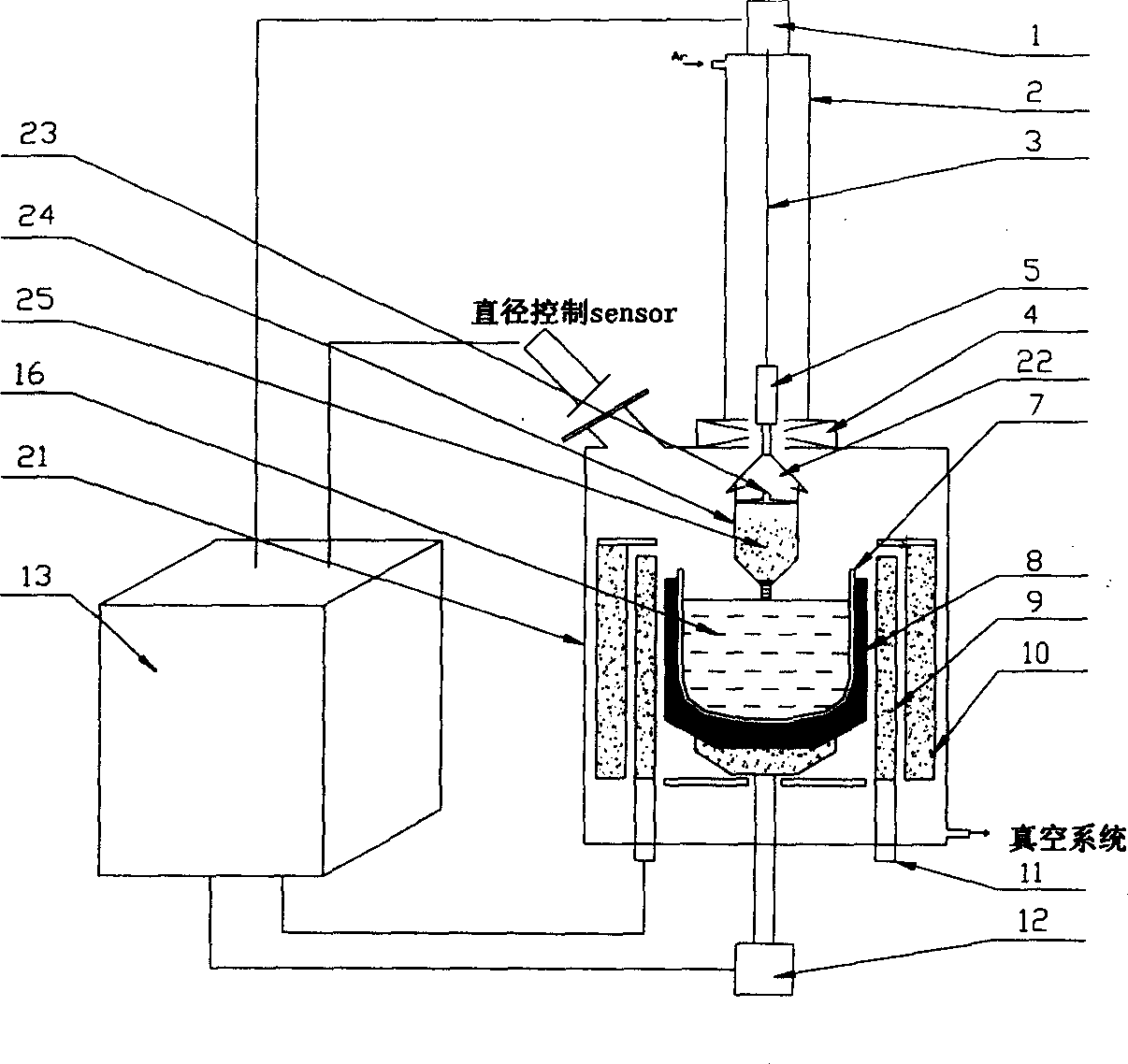

[0023] The doping funnel used for the manufacture of heavily doped Czochralski silicon single crystal has a funnel body 24, a funnel cover 23, a hook 22,

[0024] Use the doping method of doping funnel of the present invention, it is characterized in that its step is:

[0025] 1) All the polysilicon is loaded into the quartz crucible;

[0026] 2) The dopant is loaded into the doping funnel as claimed in claim 1, the funnel cover is covered, suspended under the seed chuck, and the doping funnel is raised into the auxiliary chamber, the furnace cover is covered, and the Vacuum, chemical material; after all the material is melted, lower the doping funnel to doping in the furnace of the single crystal furnace. If antimony is mixed, then lower the doping funnel to a height of 10 to 20 mm from the nozzle of the lower part of the funnel to the molten silicon surface. Let the heated and melted antimony drop into the silicon melt to be absorbed; if phosphorus or arsenic is added, lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com