Method for preparing demolding agent for roducing epoxy glass fibre reinforced plastic composite material

A technology of epoxy glass fiber reinforced plastics and composite materials, which is applied in the field of preparation of release agents for the manufacture of epoxy glass fiber reinforced plastic composite materials, which can solve the problems of poor product finish, poor finish of parts, and difficulty in uniform application, etc., and achieve simple production equipment and processes , Wide range of molding temperature, easy to apply uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

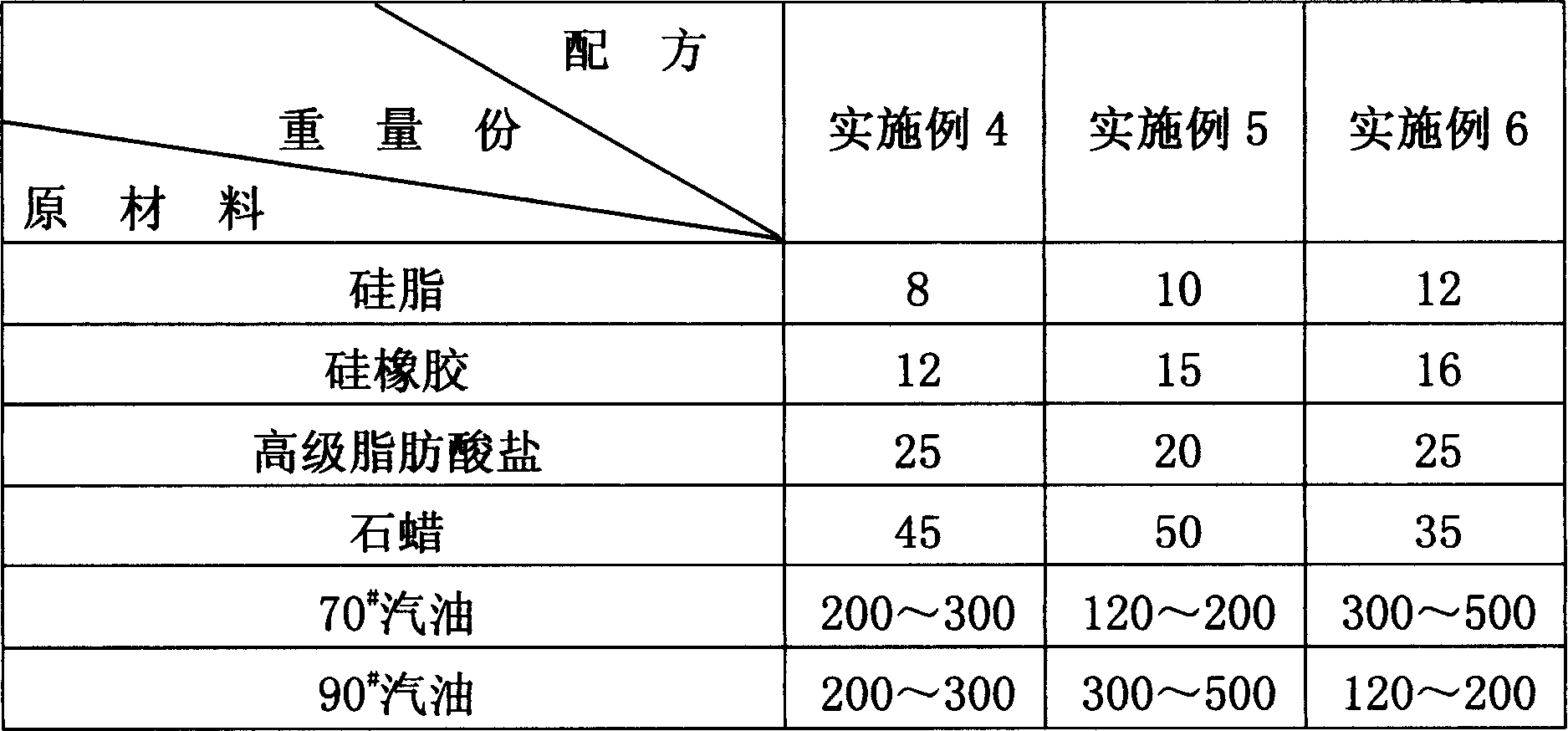

Examples

Embodiment 1

[0019] A kind of preparation method of mold release agent for the manufacture of epoxy fiberglass composite material, the silicone grease that is made by lithium saponified polyphenylmethylsiloxane by 5 parts of weight, the methyl vinyl silicone rubber of 10 parts by weight, 20 parts by weight The higher fatty acid salt (sodium lauryl sulfonate) of part weight, 75 parts by weight of 30 parts # The proportioning ratio of microcrystalline paraffin is taken respectively, adopting 70 # gasoline as a solvent;

[0020] Completely dissolve 5 parts of silicone grease with 200 parts of gasoline under heating and reflux as component 1, and completely dissolve 10 parts of silicone rubber with 100 parts of gasoline under heating and reflux as component 2, mix component 1 and component 2 Add 20 parts of higher fatty acid salts and 30 parts of paraffin in the reaction vessel in sequence at 50°C to 120°C, stir under reflux to dissolve each component into a homogeneous phase, and then obtain...

Embodiment 2

[0022] A kind of preparation method of release agent for the manufacture of epoxy fiberglass composite material, by the silicone grease that is made of methyl silicone oil by 20 parts by weight, the phenylvinyl silicone rubber of 60 parts by weight, the higher fatty acid salt of 120 parts by weight (sodium lauryl sulfate), 90 parts by weight of 90 # The proportioning ratio of microcrystalline paraffin is taken respectively, adopting 90 # gasoline as a solvent;

[0023] Completely dissolve 20 parts of silicone grease with 300 parts of gasoline under heating and reflux as component 1, and completely dissolve 60 parts of silicone rubber with 150 parts of gasoline under heating and reflux as component 2, mix component 1 and component 2 In the reaction vessel, add 120 parts of higher fatty acid salt and 90 parts of paraffin successively at 50°C to 120°C, stir under reflux to dissolve each component into a homogeneous phase, and then obtain the epoxy glass fiber reinforced plastic ...

Embodiment 3

[0025] A kind of preparation method of mold release agent for the manufacture of epoxy fiberglass composite material, take respectively the proportioning of 15 parts by weight of silicone grease, 30 parts of weight of silicone rubber, 60 parts of weight of higher fatty acid salt, and 60 parts of weight of paraffin wax amount, using 93 # gasoline as a solvent;

[0026] Completely dissolve 15 parts of silicone grease with 250 parts of gasoline under heating and reflux as component 1, and completely dissolve 30 parts of silicone rubber with 120 parts of gasoline under heating and reflux as component 2, mix component 1 and component 2 In the reaction vessel, add 60 parts of higher fatty acid salt and 60 parts of paraffin successively at 50 ° C ~ 120 ° C, stir under reflux to dissolve each component into a homogeneous phase, and then obtain the epoxy glass fiber reinforced plastic composite material. mold agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com