Field transmission magnetosensitive sensor

A magnetic sensor and field emission technology, applied in the field of magnetic sensors, can solve the problems of unsatisfactory thermal conductivity, easy damage to the top of the emitter, complicated manufacturing process, etc., and achieve low cost, improved life and sensitivity, and simple manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described more clearly below through detailed embodiments and with reference to the accompanying drawings. However, the listed embodiments of the present invention are only for describing the present invention in detail, and the embodiments of the present invention can have various forms, so the protection scope of the present invention is not limited to the embodiments.

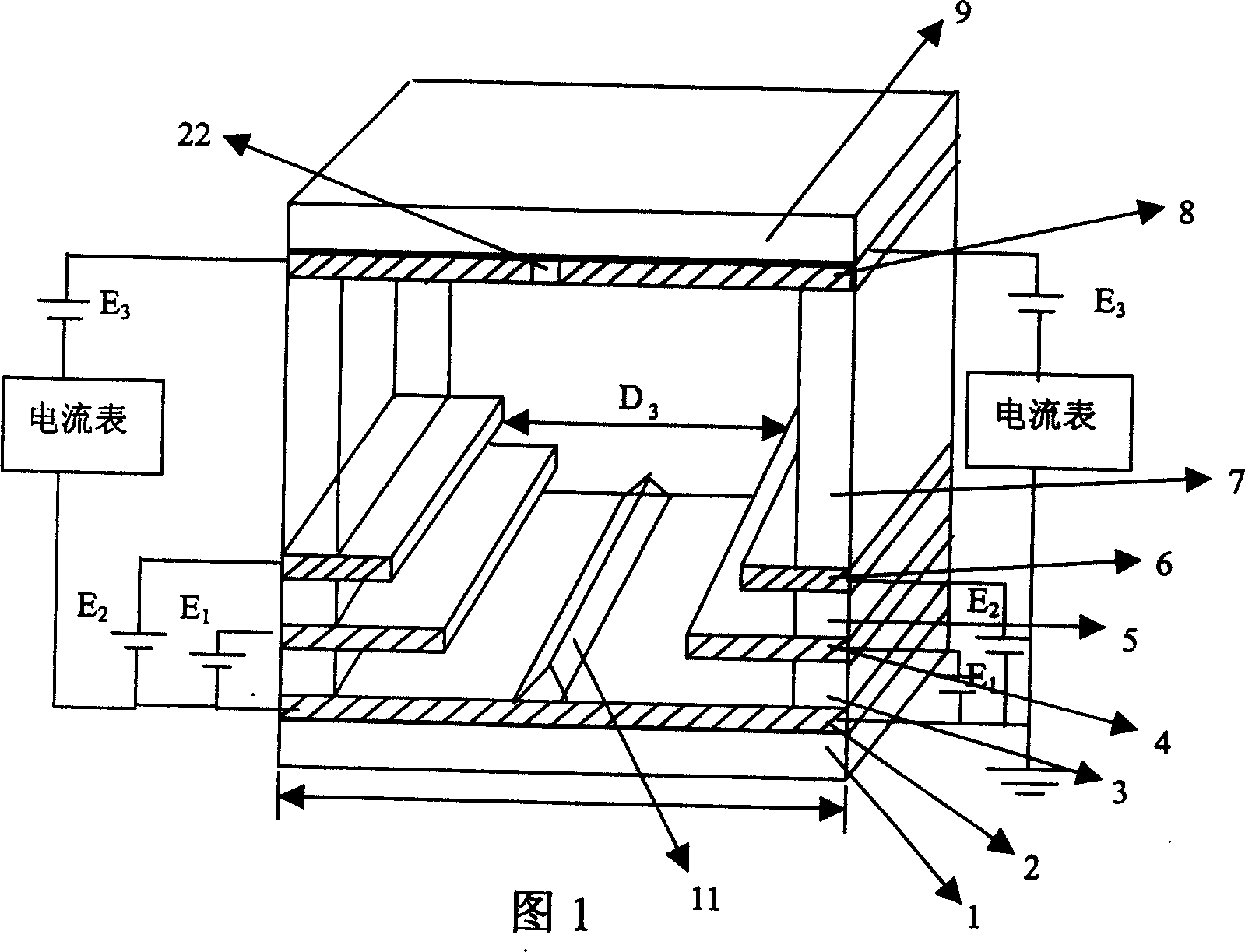

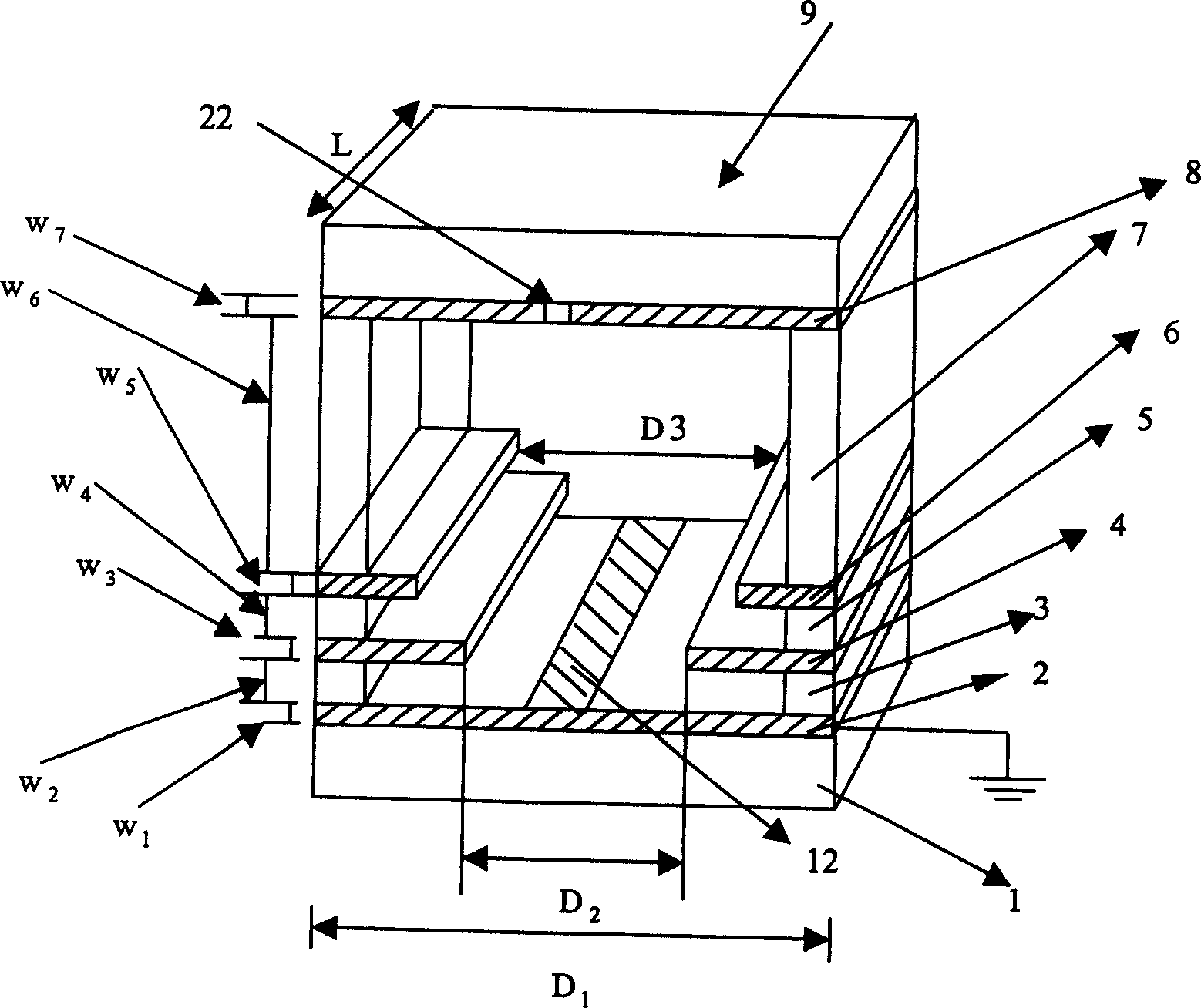

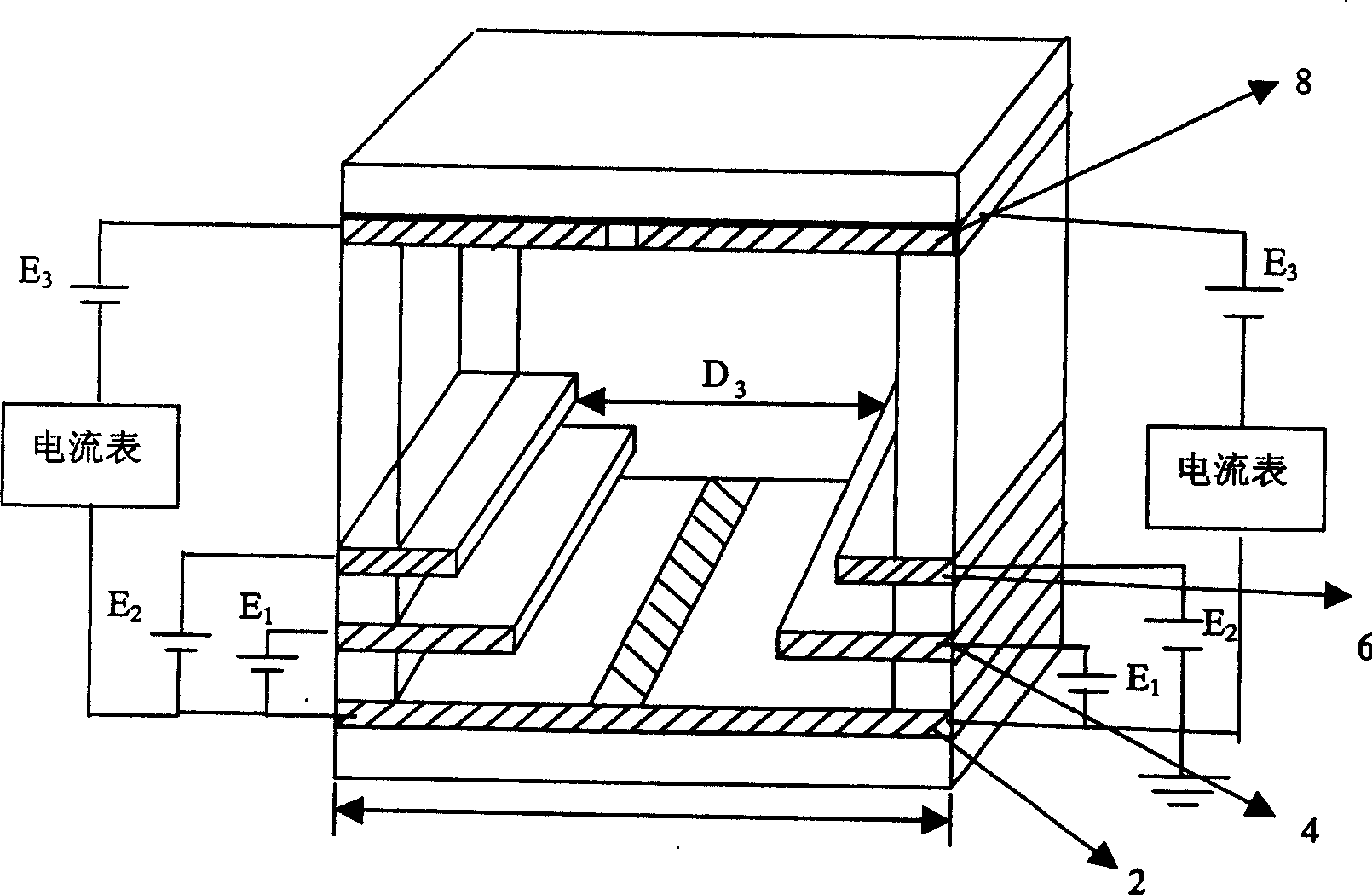

[0019] Refer to attached figure 2 , the present invention has a lower substrate 1, the first metal film 2 is on the lower substrate 1, the thickness W 1 About 1μm, length D 1 About 1mm, the first insulating film 3 is on the first metal film 2, and its thickness W 2 About 10 μm; the second metal film 4 is on the first insulating film 3, and its thickness W 3 About 1 μm, the second insulating film 5 is on the second metal film 4, and its thickness W 4 About 4 μm; the third metal film 6 is on the second insulating film 5, and its thickness W 5 About 1 μm. The middle fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com