Punching cutting assembly and folding assembly for single workpiece

A workpiece and assembly technology, which is applied in the field of single workpiece folding assembly, can solve the problems of reduced operating efficiency, complex changes in the peripheral speed of the second conveyor belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0069] (corrugated cardboard box making machine of the first embodiment)

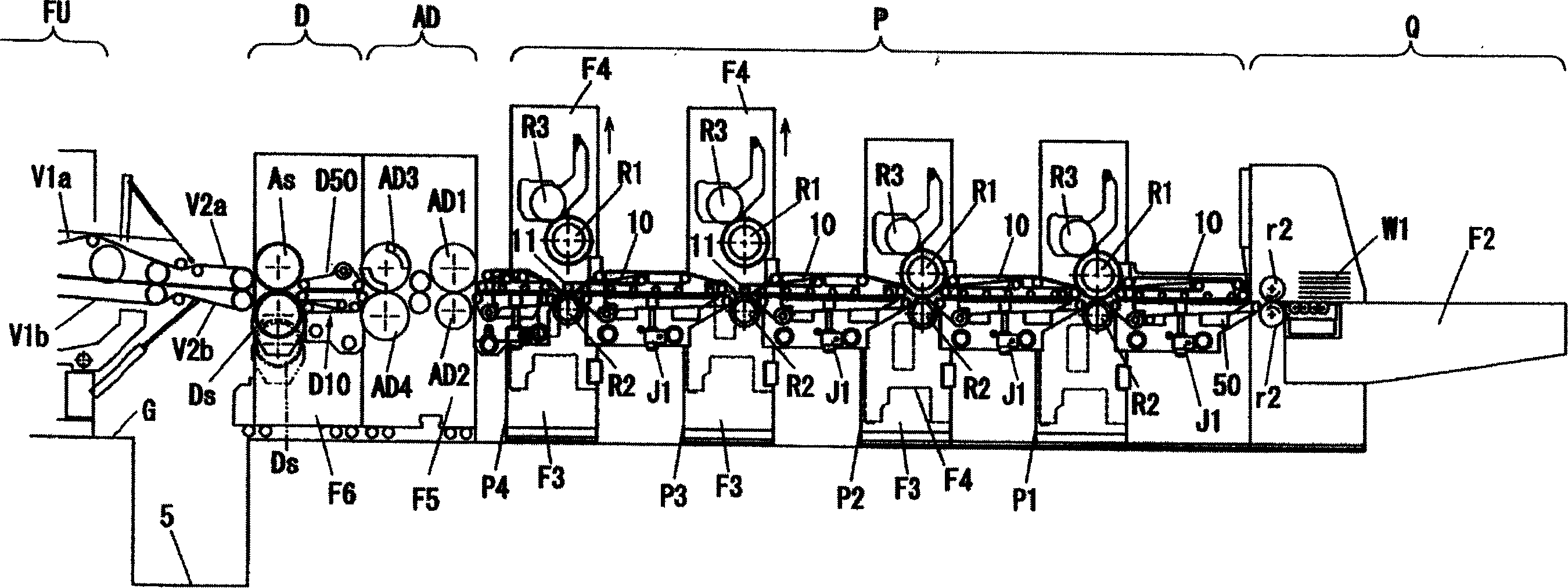

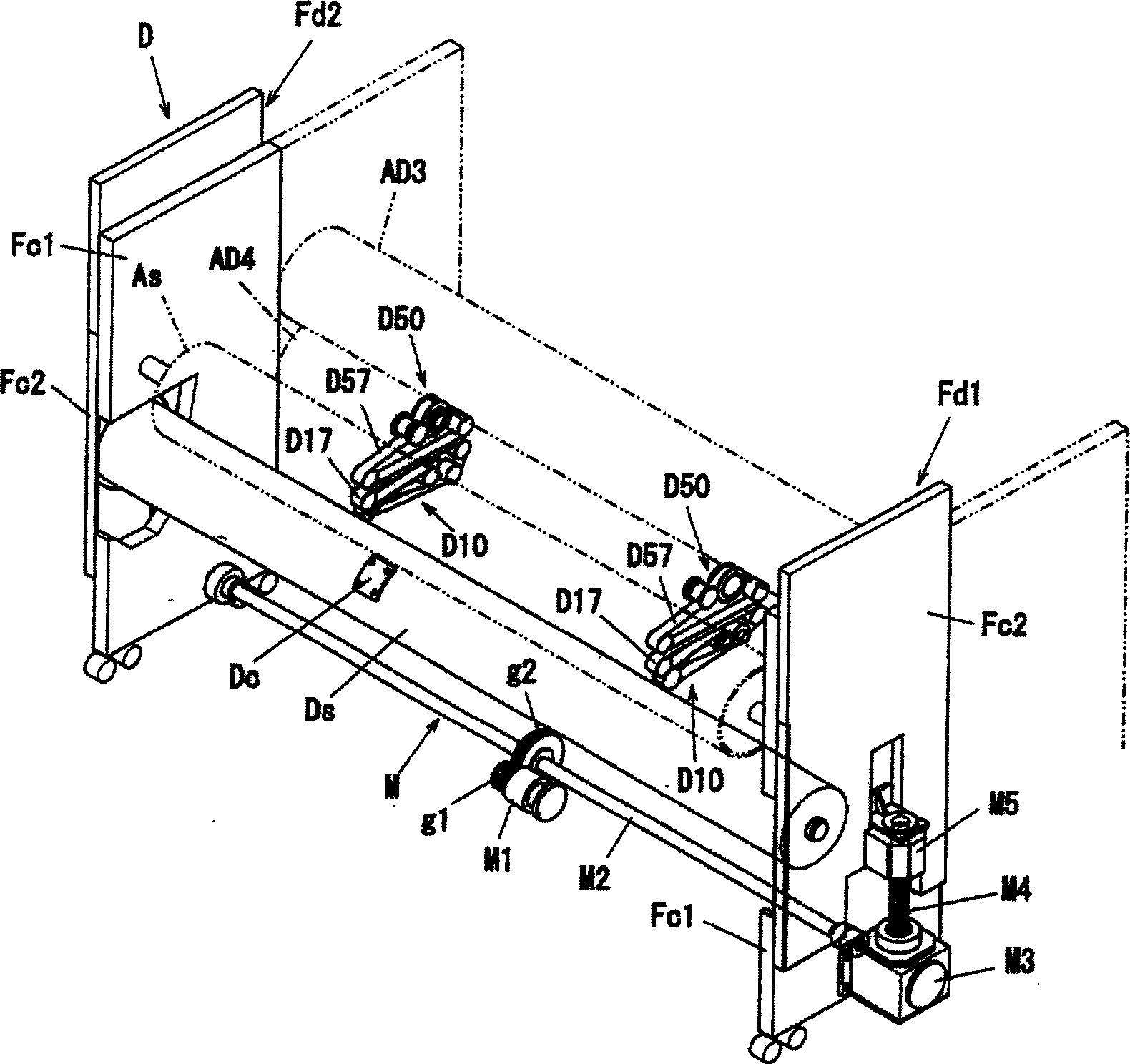

[0070] This embodiment is a corrugated cardboard box-making machine for manufacturing a corrugated cardboard box which is applied to the present invention. like figure 1 As shown, the corrugated cardboard box making machine is sequentially equipped with a paper feeding assembly Q for feeding loaded single workpieces, 4 printing units P1...P4 for printing, a slotting machine assembly AD for grooving and marking processing, punching Unit D, folding unit FU, and output unit not shown.

[0071] A single workpiece is loaded on the feeding platform F2 of the paper feeding assembly Q of the corrugated cardboard box making machine, and the single workpiece W1 sent from the paper feeding assembly Q is transported to the printing unit P1...P4, and multi-color printing is carried out through the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com