2-acetyl thiophene synthetic method using thiophene in crude benzene as material

A technology for acetylthiophene and thiophene, applied in the field of synthesizing 2-acetylthiophene, can solve the problems of poor efficiency, complicated process, low recovery rate of thiophene, etc., to avoid the destruction of thiophene resources, simple process flow, and low recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

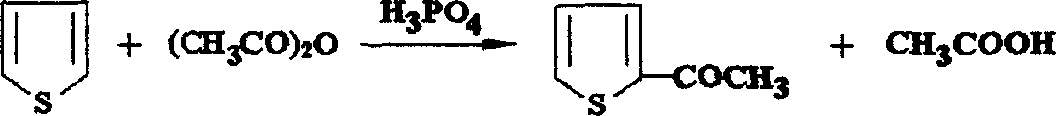

Method used

Image

Examples

Embodiment 1

[0019] Using coking light benzene containing 3350 mg / L thiophene as raw material, adopting the method introduced in the patent "A method for preparing pure benzene and concentrated thiophene from crude benzene" through one-stage and two-stage extraction and rectification to obtain thiophene containing 1.98% (by weight) respectively. ) and 19.5% (weight) of thiophene-benzene solution as raw material, with 85% phosphoric acid, Hβ zeolite molecular sieve, strongly acidic ion exchange resin, active clay, anhydrous zinc oxide, iron trichloride as catalyst, acetic anhydride is acetyl Chemical reagent, under the conditions of 40°C-90°C, normal pressure, and the molar ratio of acetic anhydride to thiophene is 2, convert thiophene into 2-acetylthiophene, the conversion rate of thiophene and the selectivity of 2-acetylthiophene of different catalysts See Table 1: Table 1 The reaction results of different catalysts catalyzing the synthesis of 2-acetylthiophene from thiophene and acetic an...

Embodiment 2

[0030] Adopting the benzene solution containing thiophene 19.5% involved in embodiment 1 as raw material, with 85% phosphoric acid, polyphosphoric acid, Hβ zeolite molecular sieve, strongly acidic ion exchange resin, anhydrous zinc chloride, iron trichloride as catalyst, Acetic anhydride is an acetylation reagent. It converts thiophene into 2-acetylthiophene under the condition of 40°C-90°C, normal pressure and the molar ratio of acetic anhydride to thiophene is 3. The conversion rate of thiophene and 2-acetylthiophene of different catalysts The selectivity of thiophene is shown in Table 2:

[0031] Table 2 Synthesis of 2-acetylthiophene from thiophene and acetic anhydride catalyzed by different catalysts

[0032] Catalyst Reaction temperature °C Material-dosage ratio * mass space velocity (h -1 ) Thiophene Conversion Rate 2-Acetylthiophene Selectivity (%)

[0033] (%)

[0034] 85% phosphoric acid 90 15 / >99.0 99.2

[0035] Po...

Embodiment 3

[0041] Using coked light benzene containing 4250mg / L thiophene as raw material, adopting the process introduced in the patent "A method for preparing pure benzene and concentrated thiophene from crude benzene" through two-stage extraction and rectification to obtain thiophene containing 24% (weight) thiophene - Benzene solution as raw material, with 85% phosphoric acid, Hβ zeolite molecular sieve, strong acid ion exchange resin, activated clay, anhydrous zinc chloride, ferric chloride as catalyst, acetic anhydride as acetylation reagent, at 40 ℃ -90 Under the conditions of ℃, normal pressure and the molar ratio of acetic anhydride and thiophene being 2, thiophene was converted into 2-acetylthiophene, the conversion rate of thiophene and the selectivity of 2-acetylthiophene of different catalysts are shown in Table 3:

[0042] Table 3 Synthesis of 2-acetylthiophene from thiophene and acetic anhydride catalyzed by different catalysts

[0043] Catalyst Reaction temperature °C Mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com