Finger cutter

A milling cutter and cutter body technology, applied in the field of finger joints, can solve the problems of large damage, reduced blade toughness, and unusable milling cutters, etc., to improve wear resistance, supplement wear resistance, and wear resistance is effective Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

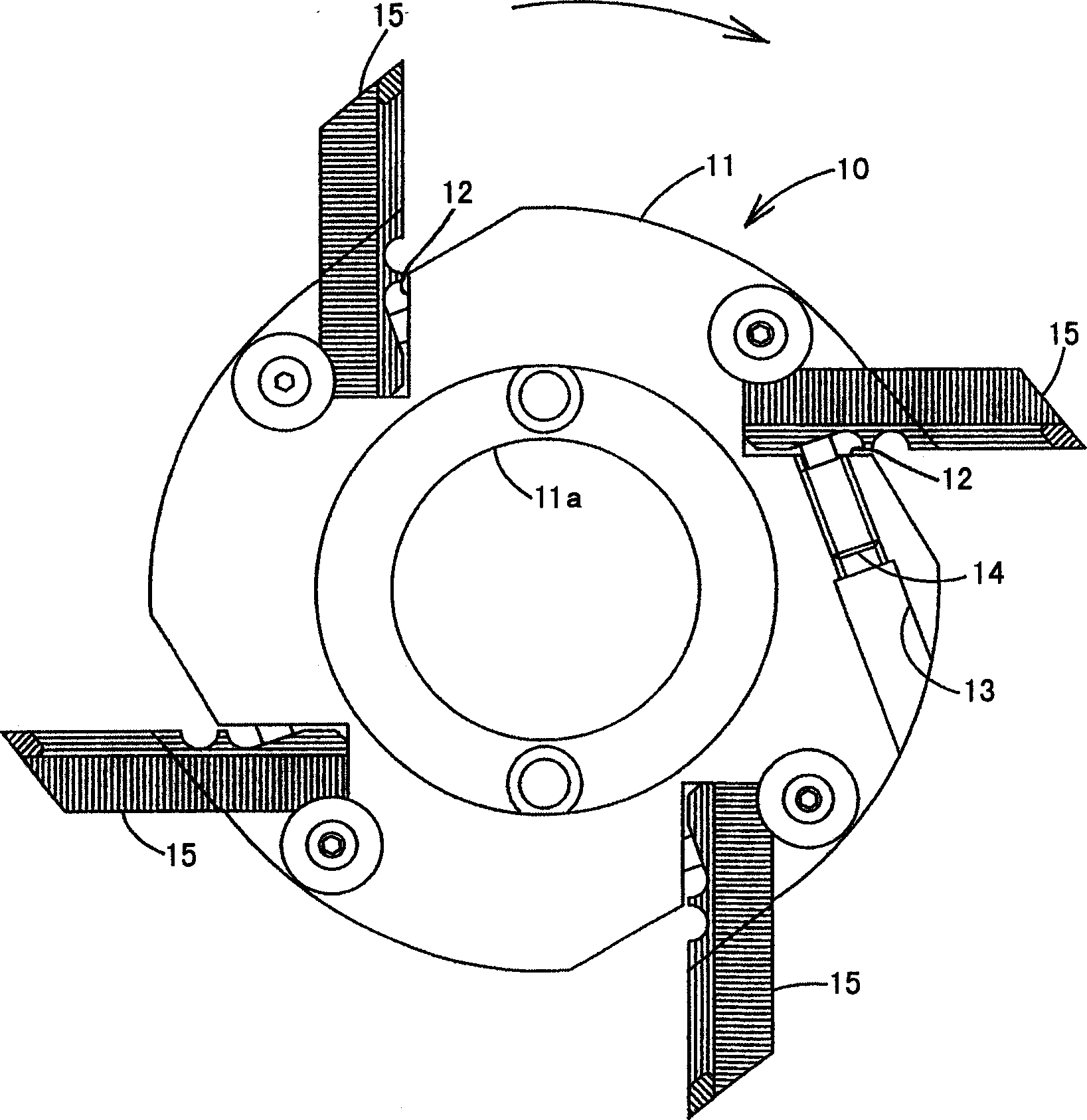

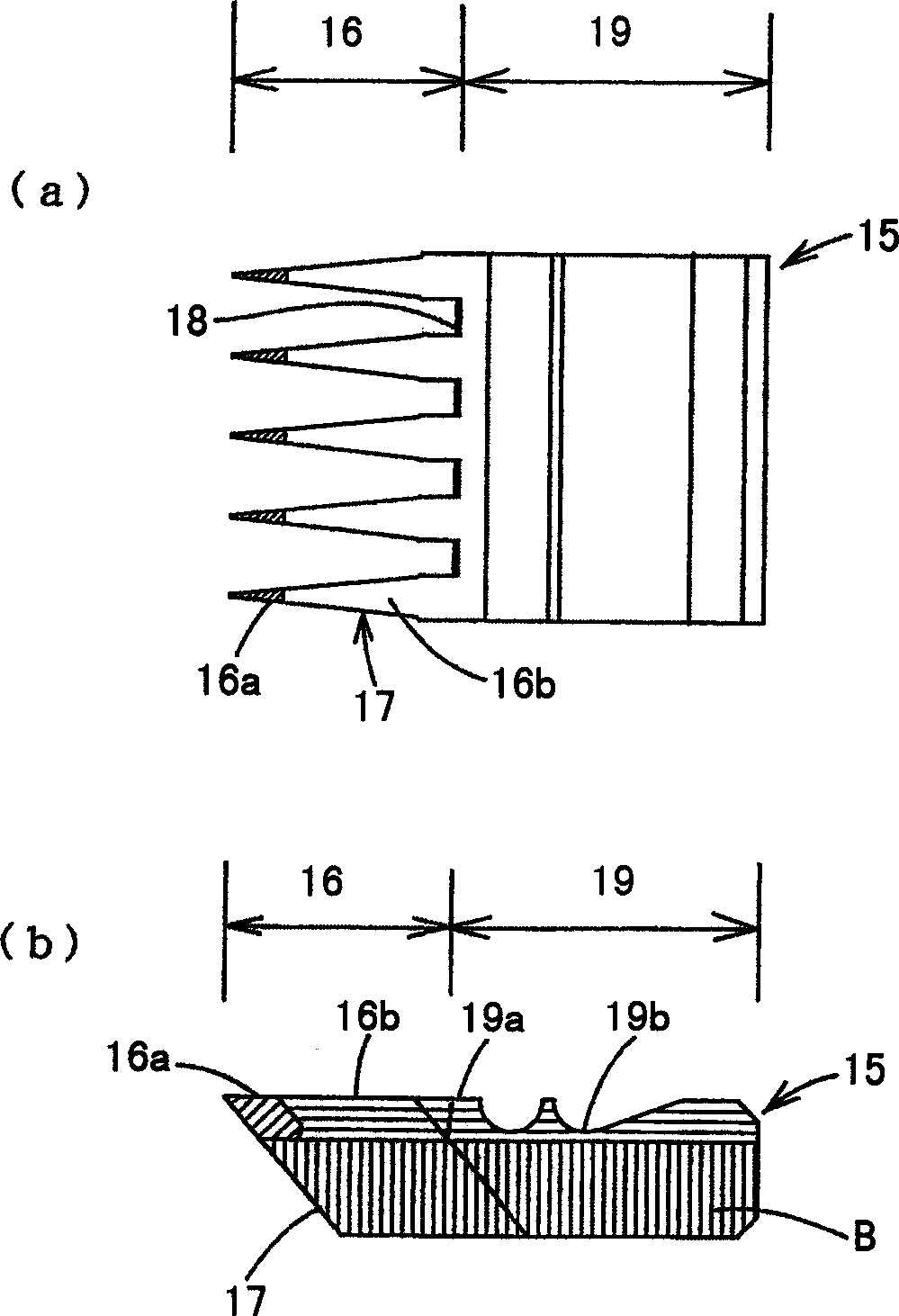

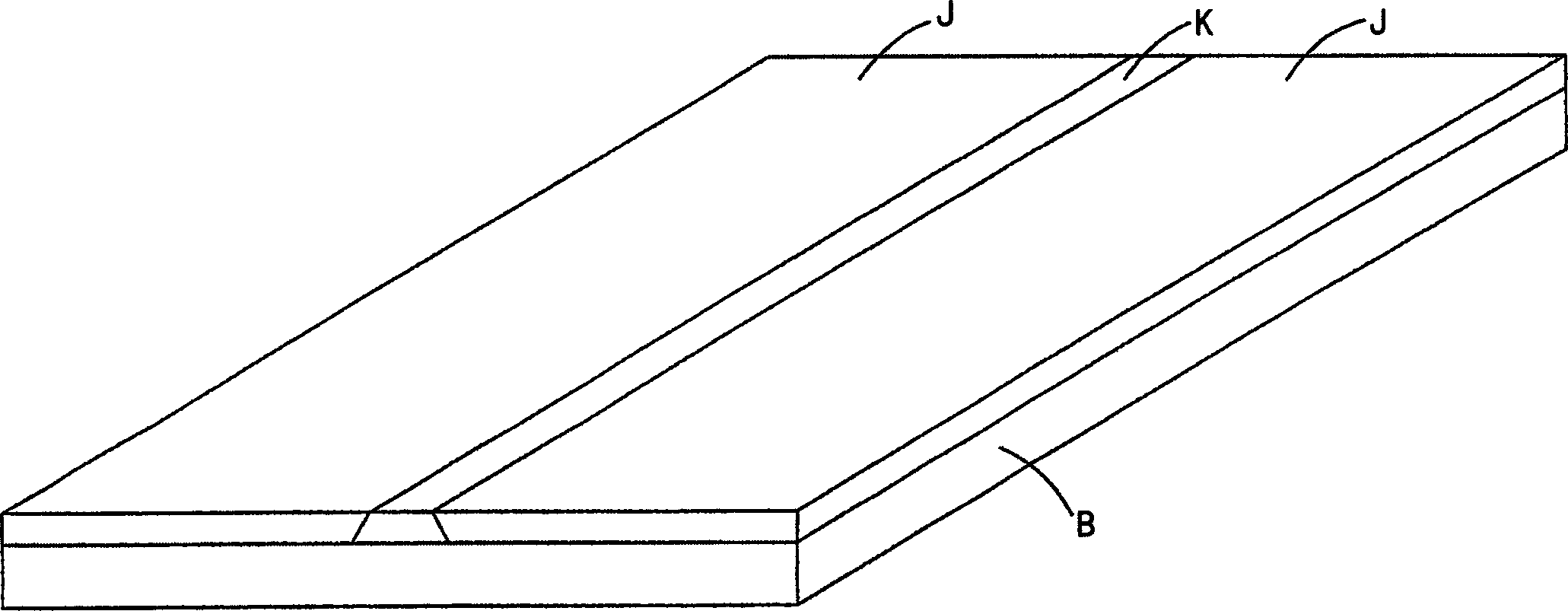

[0015] An embodiment of the present invention will be described below using the drawings. figure 1 is a side view of the replaceable edge finger milling cutter according to this embodiment, figure 2 It is a front view and a side view of the replaceable edge 15.

[0016] The finger milling cutter 10 is provided with a steel cylindrical cutter body 11. The center of the cutter body 11 has a central hole 11a for inserting into the main shaft, and four places in the circumferential direction of the peripheral wall of the cutter body 11 are provided with holes extending in the axial direction. The mount 12. The mounting seat 12 is inclined about 30° toward the front of the rotation direction with respect to the radial direction, and is a recess cut into a substantially rectangular shape. The replaceable blade 15 is inserted into the mounting seat 12 . On the outer periphery of the cutter body 11, a mounting hole 13 communicating with the mounting base 12 from the rotation fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com