Flat display panel and method of dividing the flat display panel

A flat display and liquid crystal display panel technology, applied in stone processing equipment, instruments, glass manufacturing equipment, etc., can solve the problems of longer processing flow and lower product value, and achieve the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below with reference to the drawings.

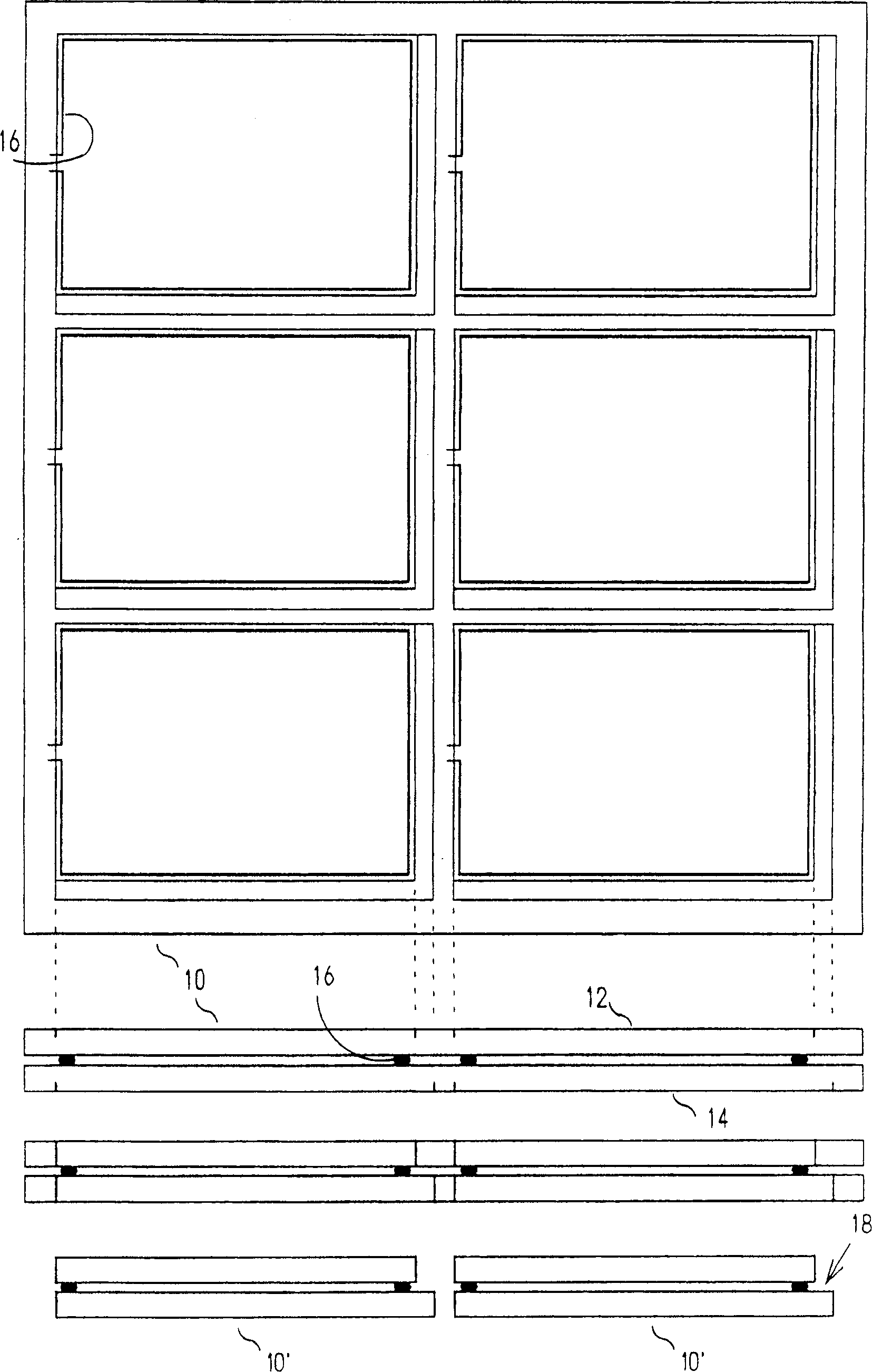

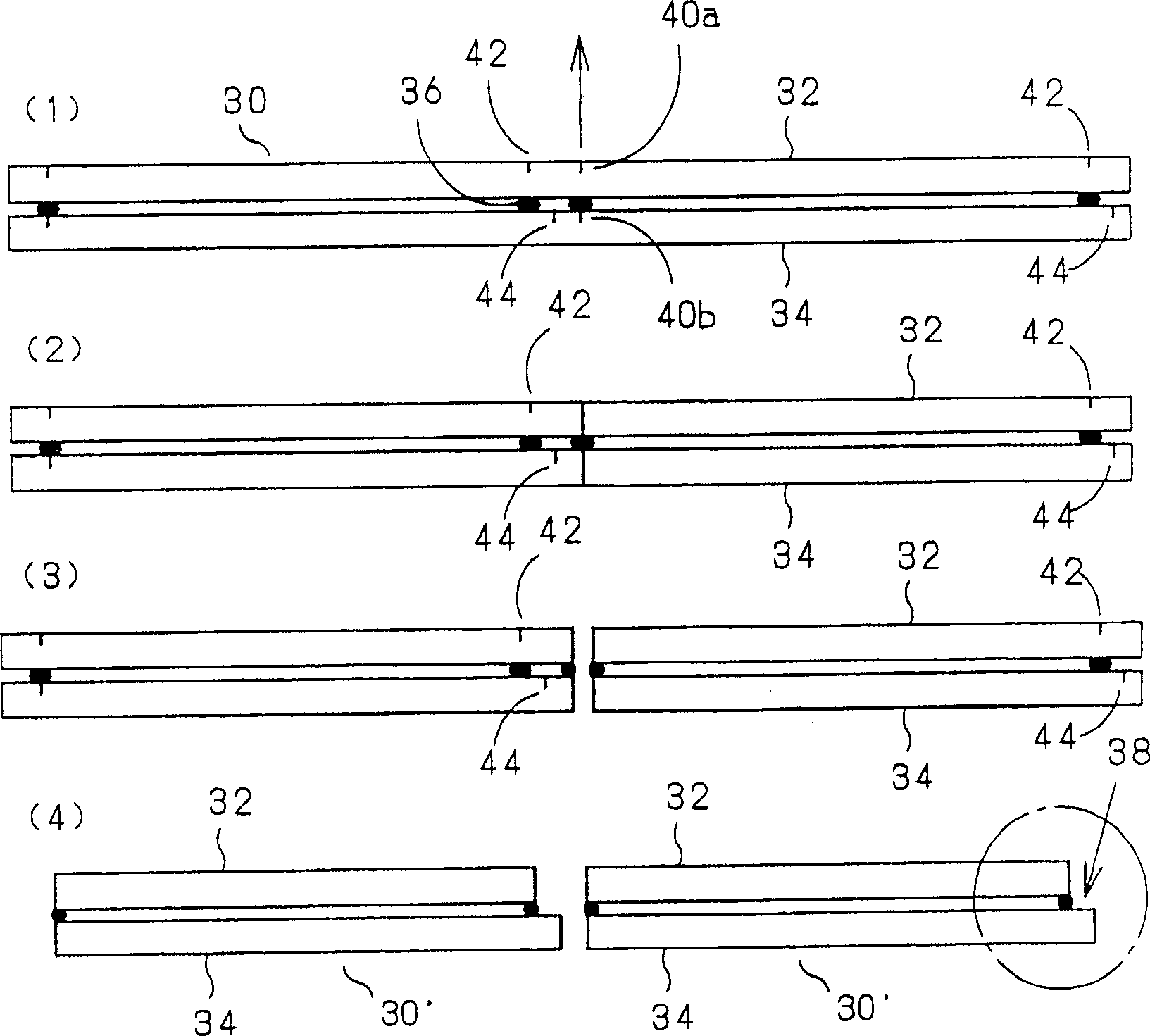

[0028] image 3 It is a figure for demonstrating the manufacturing method of the liquid crystal display panel which is one kind of flat display panel of this invention. A large-sized liquid crystal display panel 30 is manufactured by making two glass substrates 32 and 34 face each other and bonding them together with a sealant 36 . On the inner surfaces of the glass substrates 32 and 34 , various electronic control circuits (TFT arrays, etc.) required for display functions are formed. In addition, between the two glass substrates 32 and 34, a part of the sealing material 36 is opened to form a gap for introducing a functional material (liquid crystal). In addition, the terminal portion 38 is a portion serving as a terminal of a TFT array formed on one glass substrate 34 . The composition and figure 1 The prior art examples shown are identical. Scribe lines 40a are formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com