Cam type plastic flat filament coiling machine

A technology of plastic flat wire and winder, which is applied in thin material handling, conveying filamentous material, transportation and packaging, etc., can solve the problems of wear of sliders and spiral grooves, high sides at both ends, high power loss, etc. Achieve the effect of smooth reciprocating motion and reversing, easy and smooth movement, and improved winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

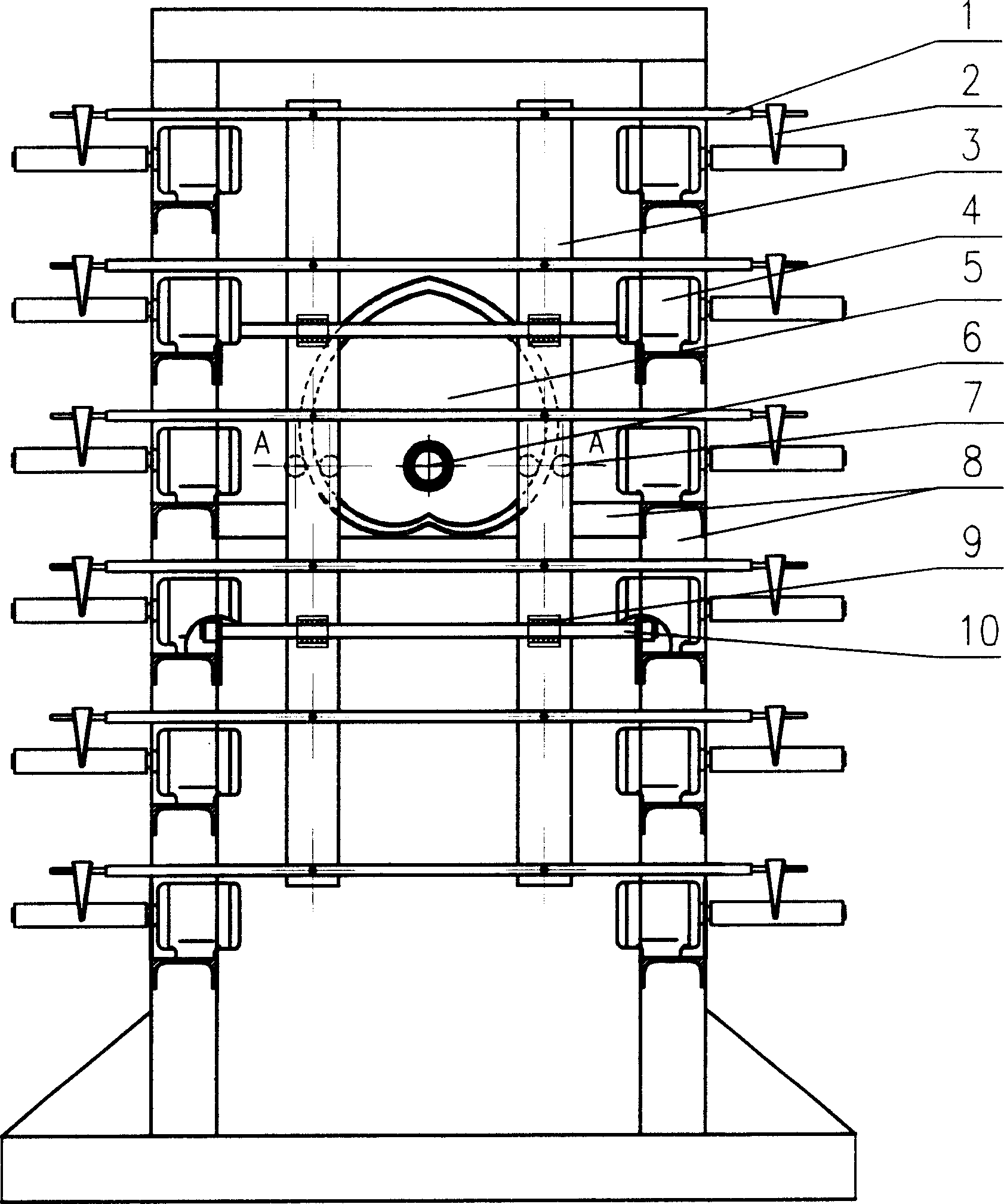

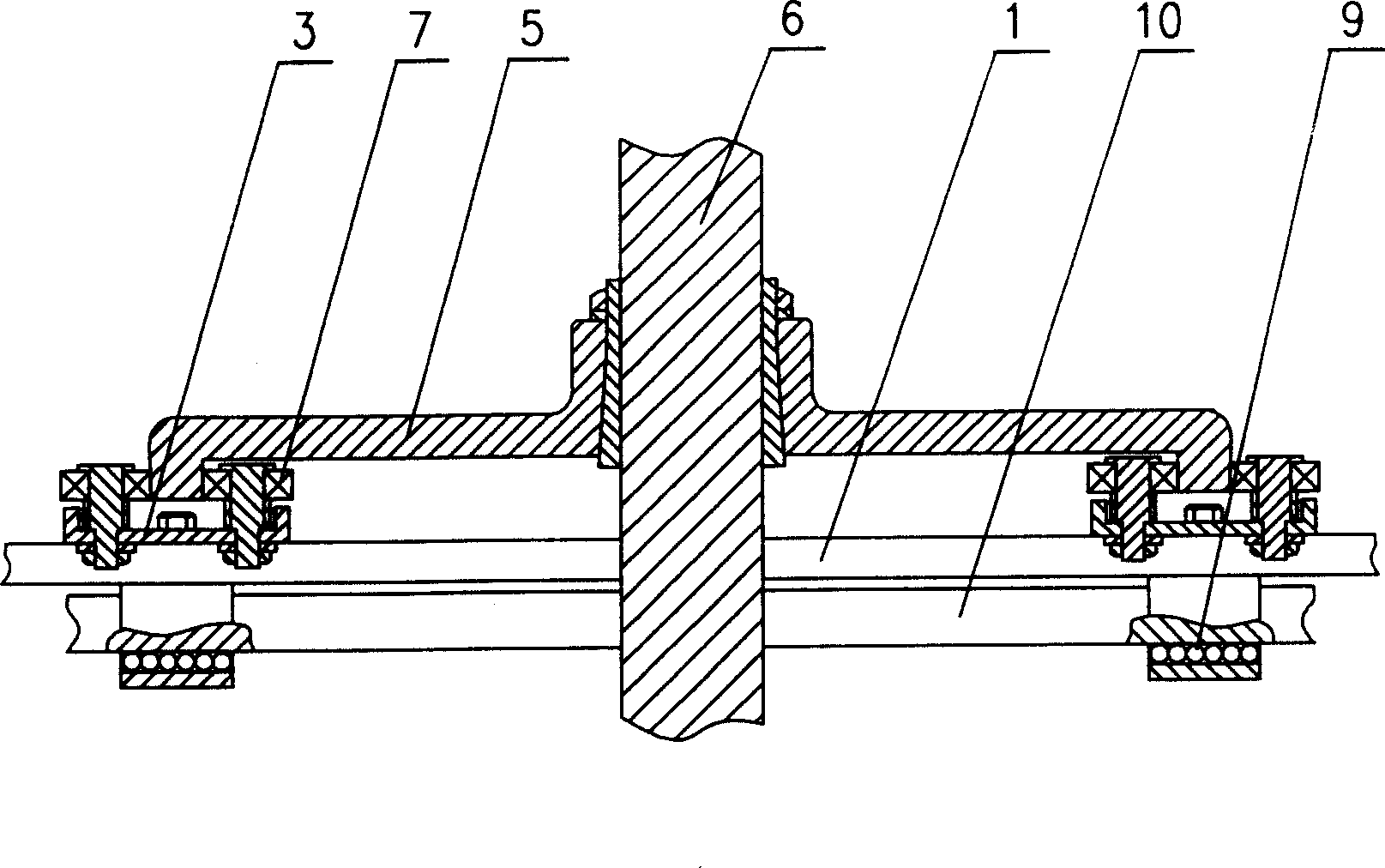

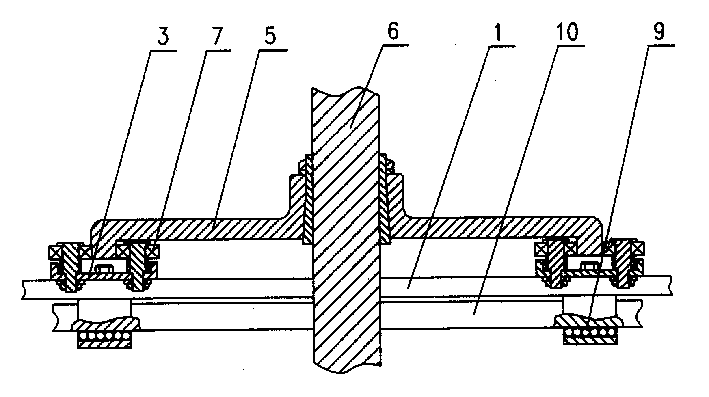

[0011] Refer to figure 1 , The whole machine is composed of a guide wire rod 1, a guide wire duckbill 2, a moving frame 3, a torque motor 4, a cam 5, a main shaft 6, a rolling bearing 7, a frame 8, a bearing 9, a guide shaft 10, etc. On both sides of the frame (8) are installed 4-6 layers of torque motors (4), the main shaft (6) is fixedly equipped with a cam (5), and the edge of the cam (5) has a rolling bearing (7) on both sides of the curved bosses on the left and right sides. ), the rolling bearing (7) is fixedly mounted on the left and right moving frames (3), and the moving frame (3) is additionally fixedly equipped with 4-6 layers of guide screw rods (1), and the two ends of the guide screw rods (1) are installed Guide wire duckbill (2). A bearing (9) is fixed on the moving frame (3), and the bearing (9) is in rolling fit with the guide shaft (10). The two ends of the guide shaft (10) are fixedly mounted on the frame (8). The cam (5) is a heart-shaped cam.

[0012] Refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com