Process and apparatus for the production of calcium bromide by liquid-liquid extraction

A production method and technology of calcium bromide are applied in directions such as magnesium bromide, calcium/strontium/barium bromide, magnesium chloride, etc., and can solve problems such as not considering problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

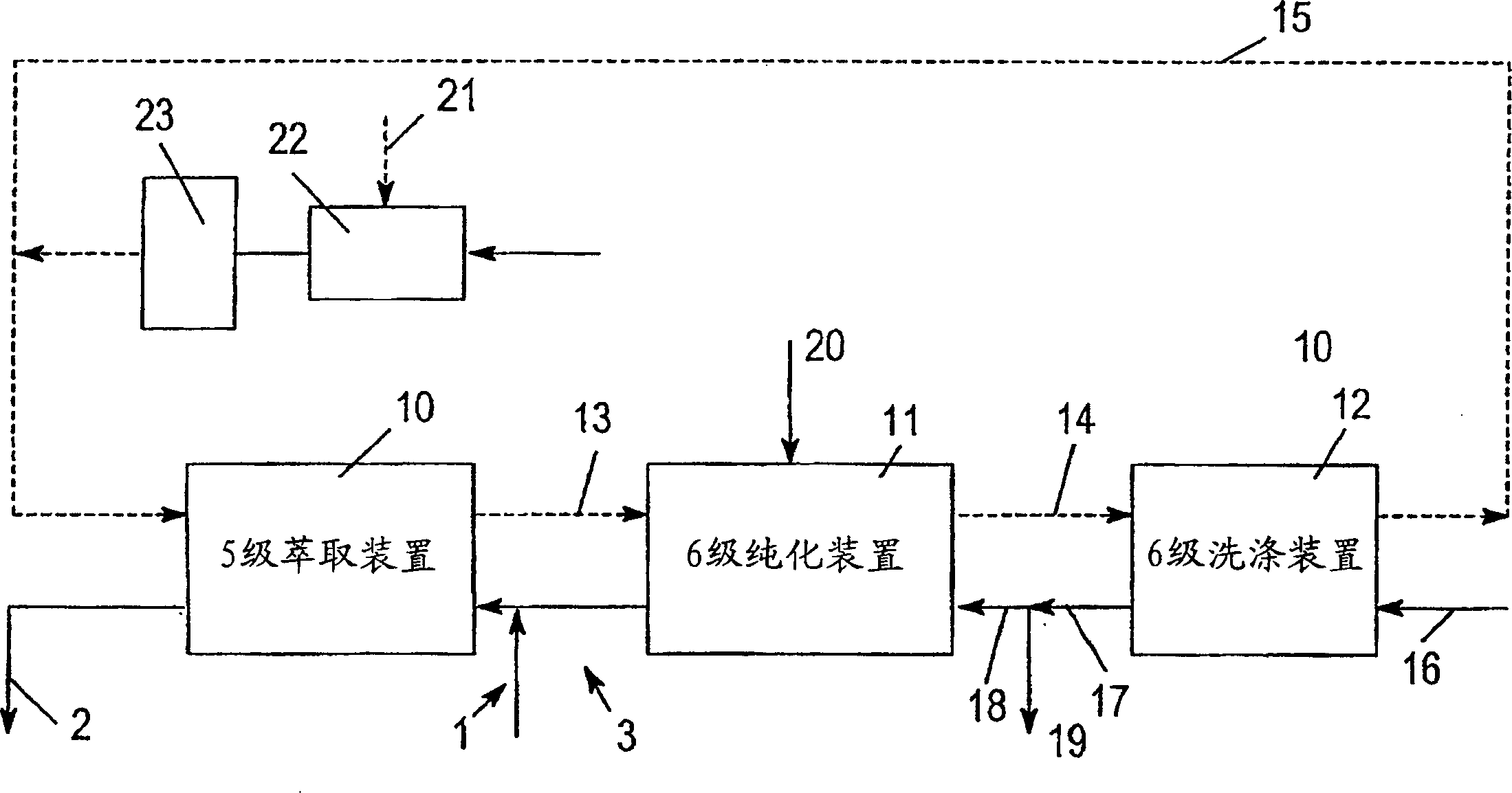

[0077] The following is based on figure 1 Representative results of the summer run (August) of the process flow diagram. The obtained parameters are as follows:

[0078] Brine composition: 0.90% Br - , 26.2% Cl - .

[0079] Flow rate: raw brine 43m 3 / hr, solvent 85m 3 / hr, washing water 3.6m 3 / hr.

[0080] Yield: 1110 1t / hr of 18.5% CaBr 2(490kg 52% CaBr 2 , 0.7% Cl in this 52% product - ).

[0081] Br - Extraction rate: 37%.

[0082] Representative concentration:

[0083] Depleted brine: 0.53% Br - , 24.4% Cl - .

[0084] Extract: 1.2% Br - , 1.2% Cl - .

[0085] Washed Solvent 0.03% Br 2 .

[0086] Percentages here and thereafter are by weight unless otherwise indicated.

[0087] liquid flow

Embodiment 2

[0089] liquid flow

Embodiment 3

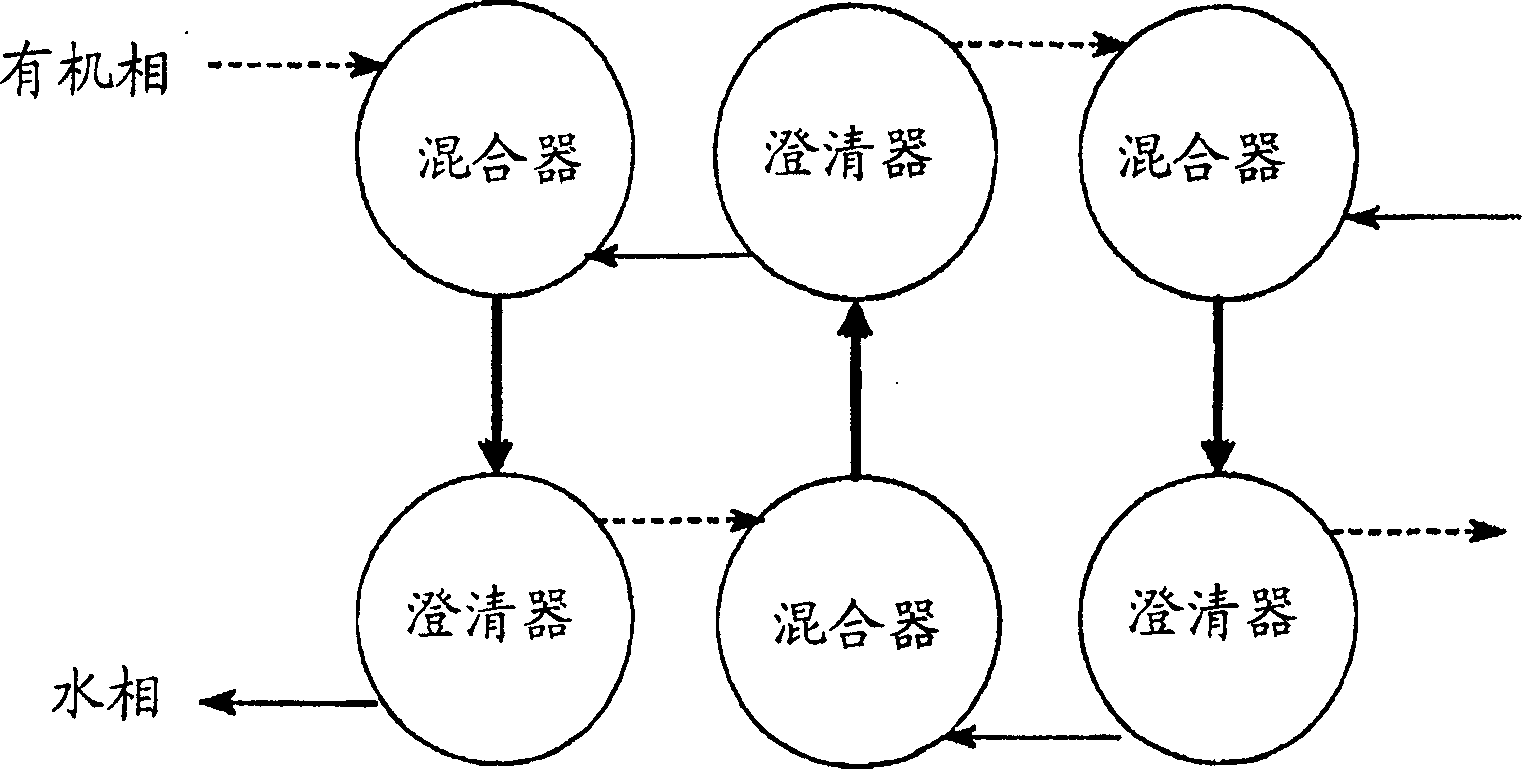

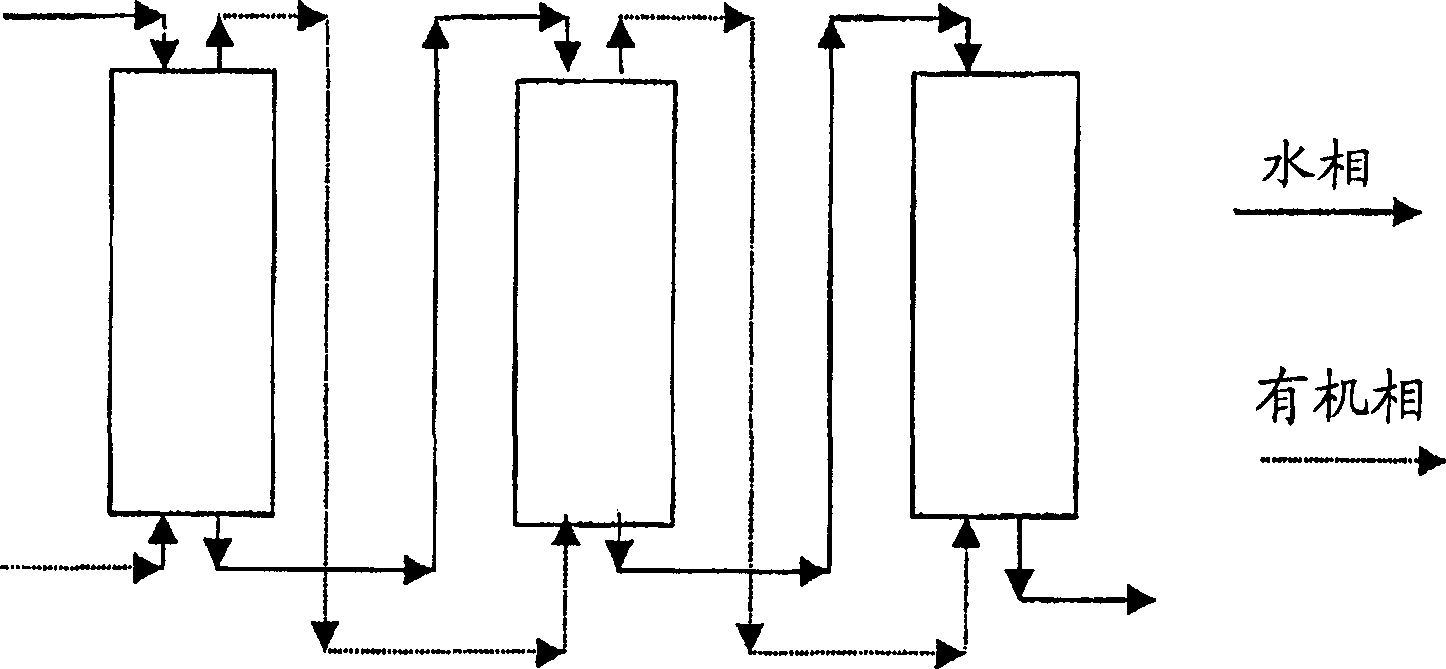

[0091] This example refers to a summer operation (temperature 50° C.) carried out in an intermediate plant consisting of a nine-stage mixer-clarifier, where 45 l / h of specific Dead Sea brine meets 85 l / h of washed solvent. The extract was washed with 6 l / h of distilled water without any purification. Stage five is used for extraction and stage four is used for washing.

[0092] The introduced brine contained 26.7 wt% Cl, 0.92 wt% Br and 4.08 wt% Ca ++ and 6.8 wt% Mg ++ . The product has 5.2 wt% Br - and 17.1 wt% Cl - . 85% by weight of Br in the raw brine - is extracted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com