Electric plasm glue processing method for shoes material

A processing method and technology for shoe materials, which can be applied to footwear, other household appliances, household appliances, etc., can solve problems such as cost, increase in production cost, and human injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to achieve the above-mentioned purpose and technology, the detailed means and effects thereof adopted by the invention of this case are now given a preferred embodiment and explained in detail in conjunction with the drawings.

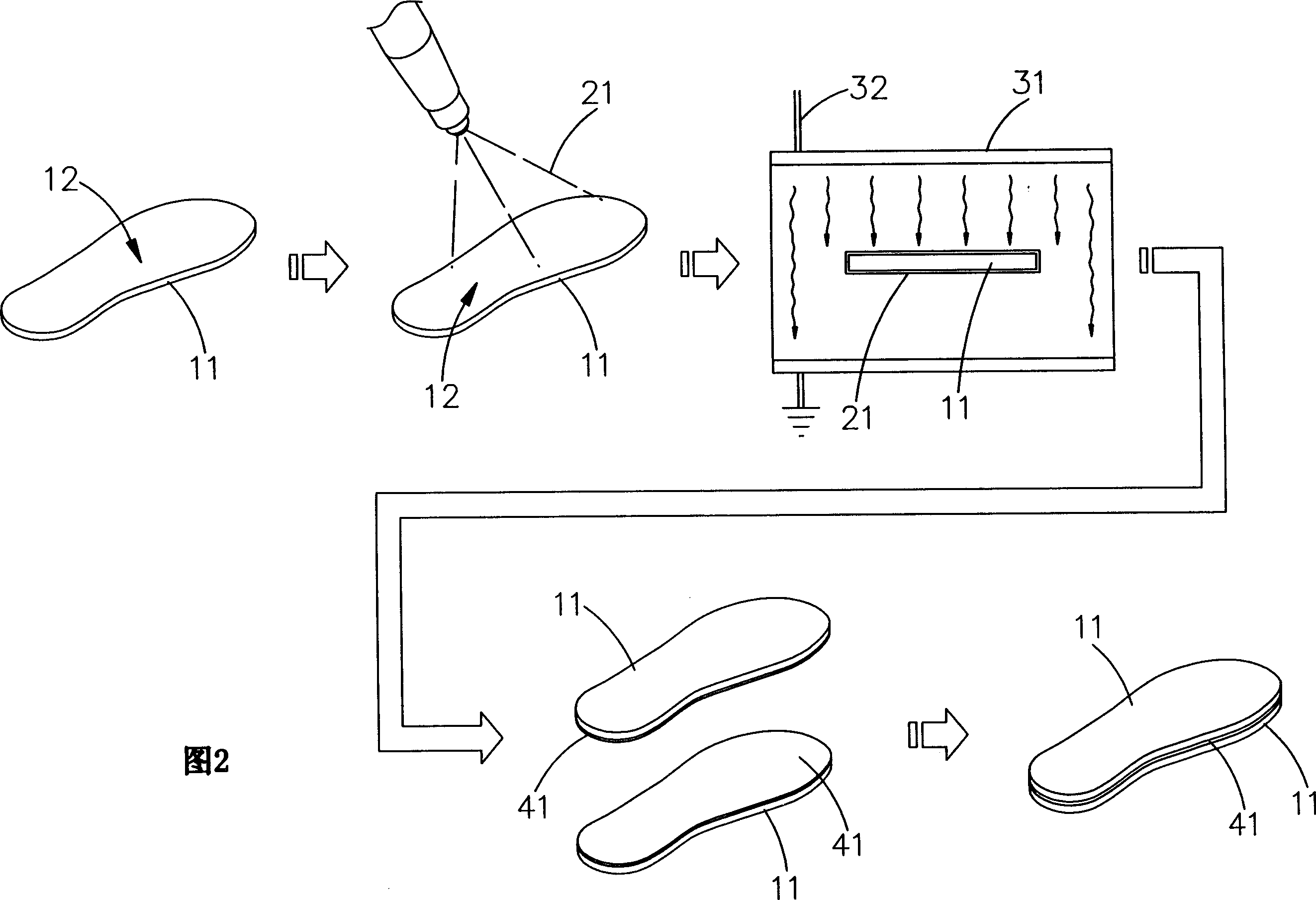

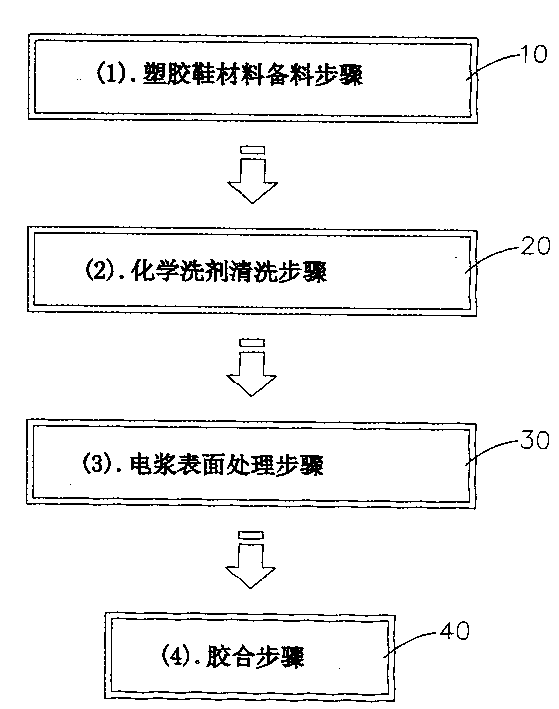

[0022] The purpose, characteristics and advantages of the invention in this case, as well as specific understanding; also refer to figure 1 , shown in Fig. 2, the present invention is to carry out according to following steps:

[0023] 1. Plastic shoe material preparation step 10: prepare the preset plastic shoe material 11 to be glued (for example: the outsole and midsole of the sole), and make a surface 12 to be glued on the plastic shoe material 11;

[0024] 2. Chemical lotion wiping step 20: use the preset chemical lotion 21 (for example: ketone chemical lotion) to wipe the plastic shoe material 11, so that the surface 12 of the plastic shoe material 11 to be glued is covered with the chemical lotion 21;

[0025] 3. Plasma surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com