Tester for measuiring bending stress and strain of refractory materials under high temperature

A refractory material and bending stress technology, applied in the field of testers, can solve the problem of not being able to test the amount of deformation, and achieve the effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: Test method for high-temperature bending stress-strain relationship of refractory materials

[0033] 1. Prepare the sample: Cut a cuboid sample of 25×25×125 on the second-grade high-alumina brick, measure the width and height of the middle part of the sample with a vernier caliper, and input the data into the computer.

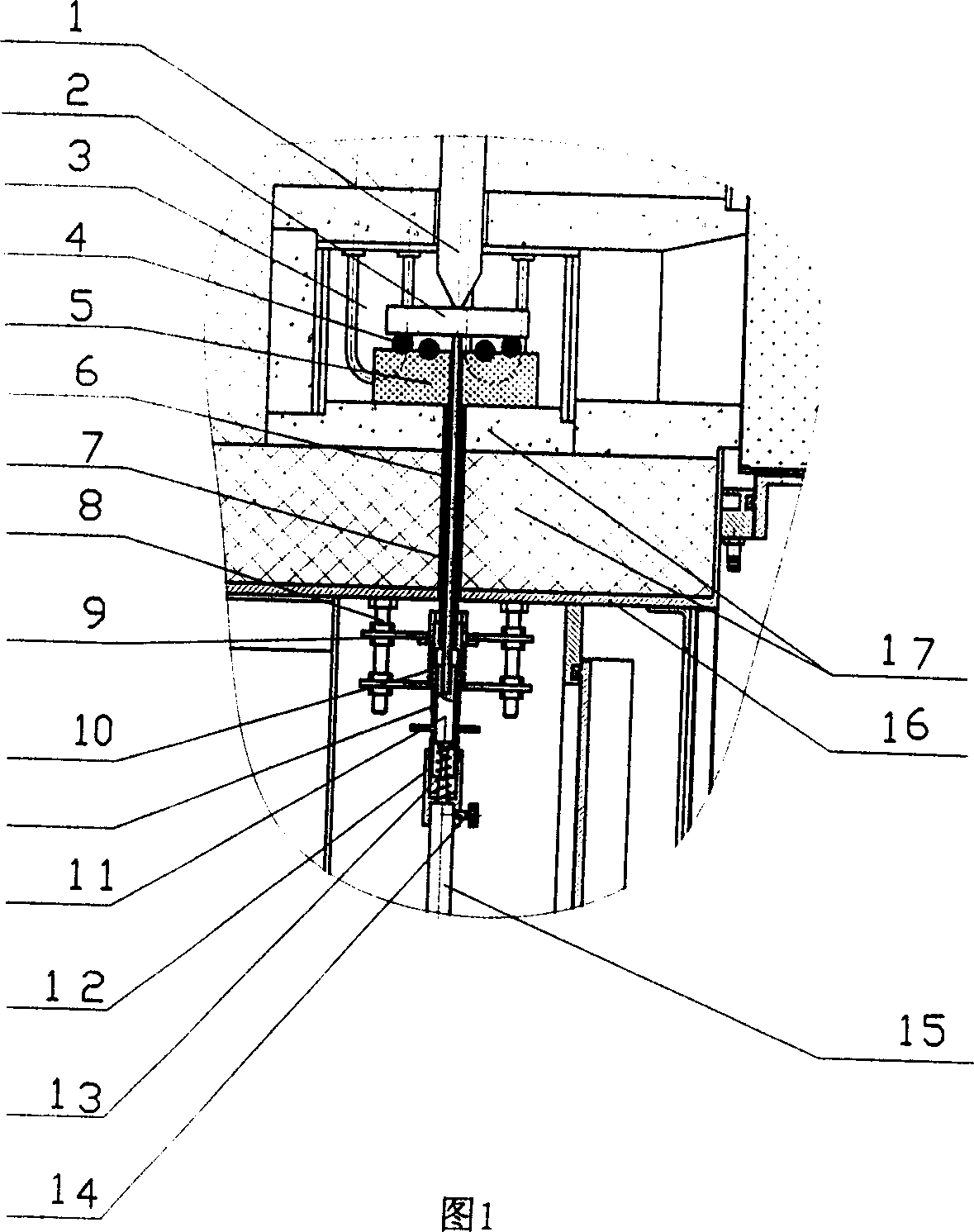

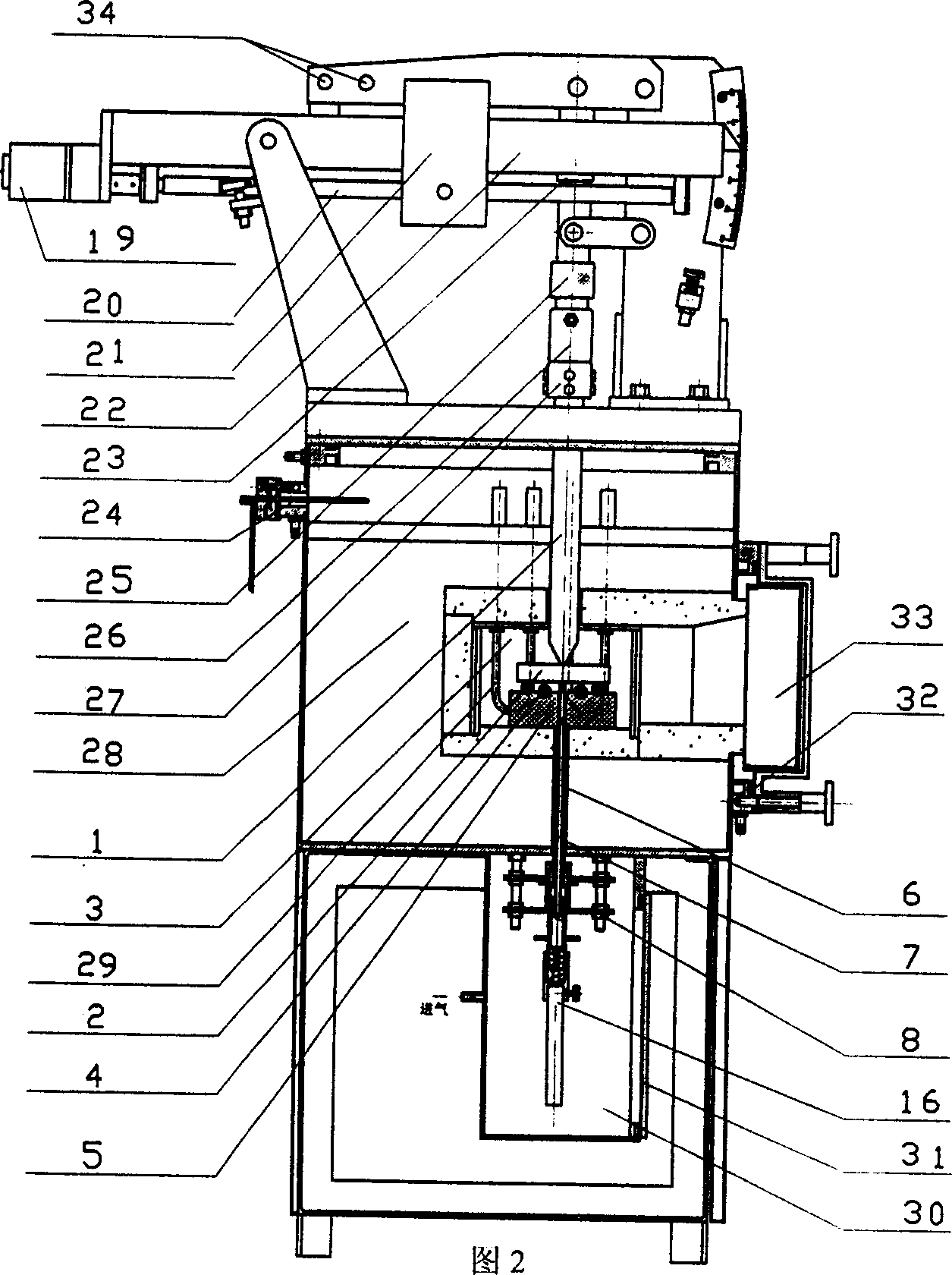

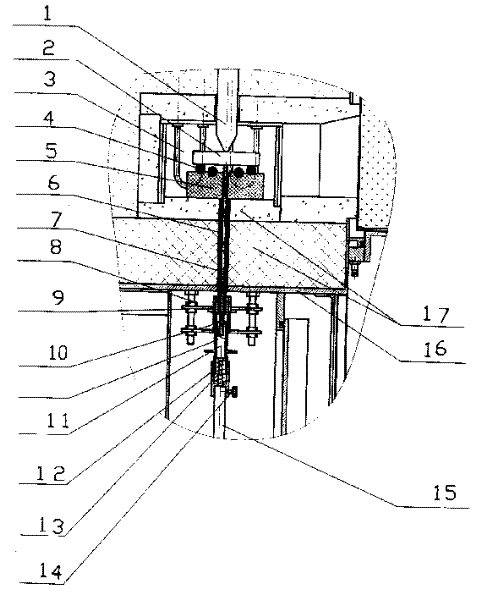

[0034] 2. As shown in Figure 2, put the sample on the lower edge fulcrum 4 in the furnace 3, adjust the height of the inner differential tube 6 so that it touches the bottom of the sample, close the furnace door 33, and turn on the power of the main engine switch.

[0035] 3. At room temperature with 10N / cm 2 The loading speed of .s applies bending stress to the sample. When the stress value reaches 8MPa, the stress is released at the same speed immediately. During the stress reciprocating process, the deformation of the sample is recorded every 1MPa. The stress-strain curve of the second-grade alumina brick.

[0036] 4. Heat the sample to...

example 2

[0039]Example 2: Test of high temperature flexural strength and corresponding maximum deformation of refractory materials:

[0040] 1. The steps are the same as 1 and 2 of Example 1.

[0041] 2. Increase the temperature according to the following program. 0~1000℃: 10℃ / min; 1000℃~1400℃: 5℃ / min; keep warm at 1400℃ for 30min. When the heat preservation is over, use 10N / cm 2 The loading rate of S is applied to the sample until the sample breaks, and the computer will automatically record the maximum stress and the corresponding maximum bending deformation of the sample when it breaks.

example 3

[0042] Example 3: Test of high temperature bending creep deformation rate of refractory materials

[0043] 1. The steps are the same as 1 and 2 of Example 1.

[0044] 2. Heat up and keep warm according to the following program: 0-1000°C, 10°C / min; 1000°C-1300°C, 5 / min; 1300°C. Keep warm for 210min.

[0045] 3. When the holding time reaches 30 minutes, use 8N / cm 2 . S loading rate to load the sample, when the stress value reaches 0.2Mpa, stop loading, observe and record the bending deformation and time relationship of the material under constant temperature and constant pressure.

[0046] 4. According to the formula, calculate the high temperature bending deformation rate of the refractory material, the calculation formula is as follows:

[0047] P ( % ) = Ln - Lo Li × 100 %

[0048] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com