Ink jetting recording device

An inkjet recording and equipment technology, applied in printing, printing devices, etc., can solve the problems of reduced collection efficiency, complex equipment structure, and increased output printing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

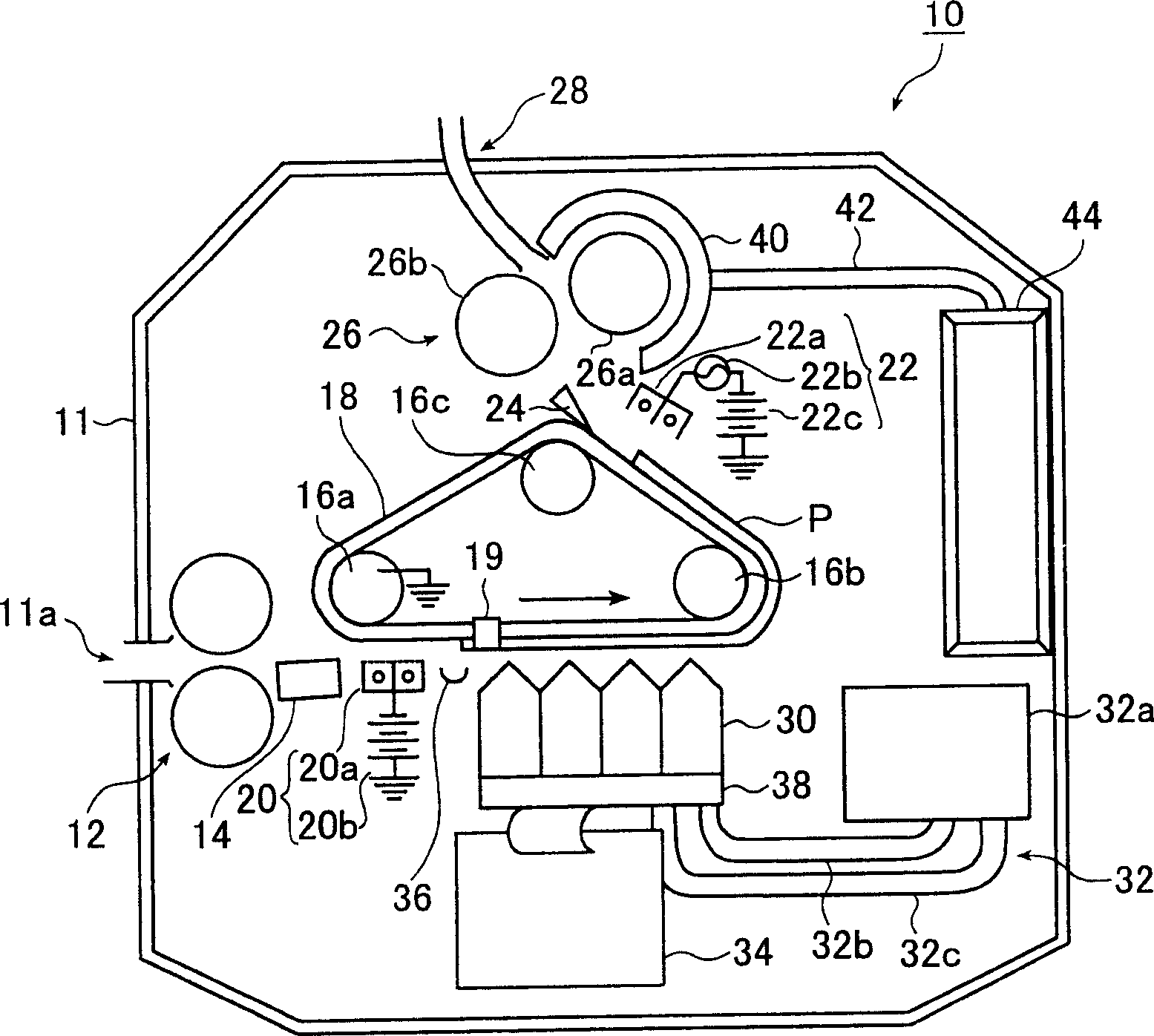

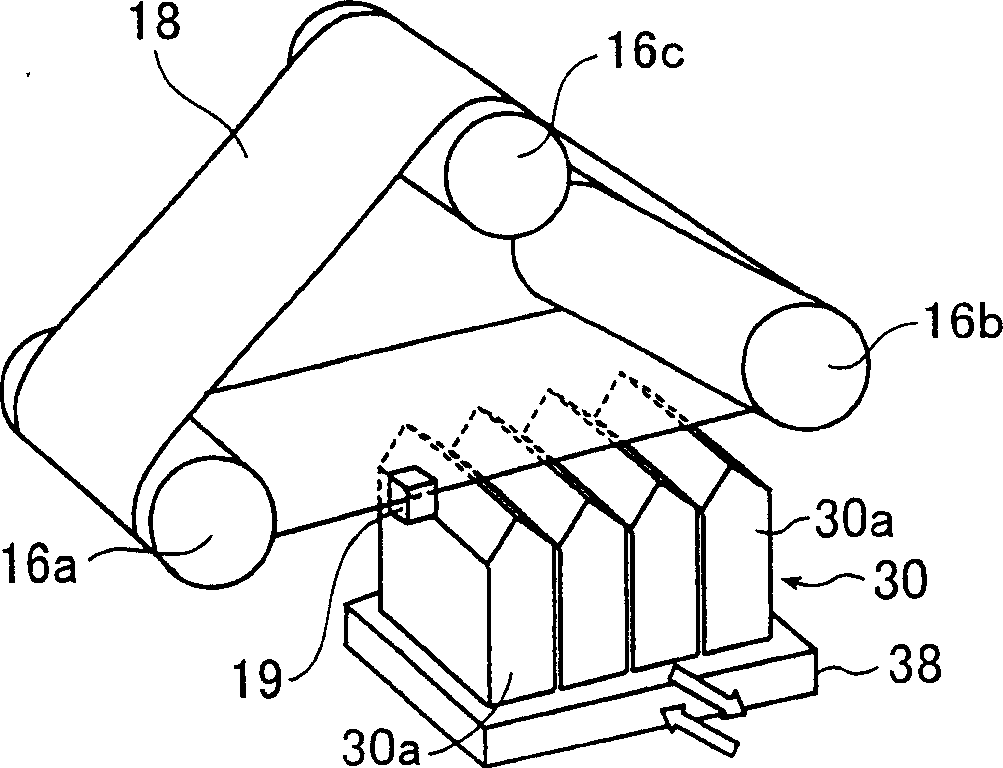

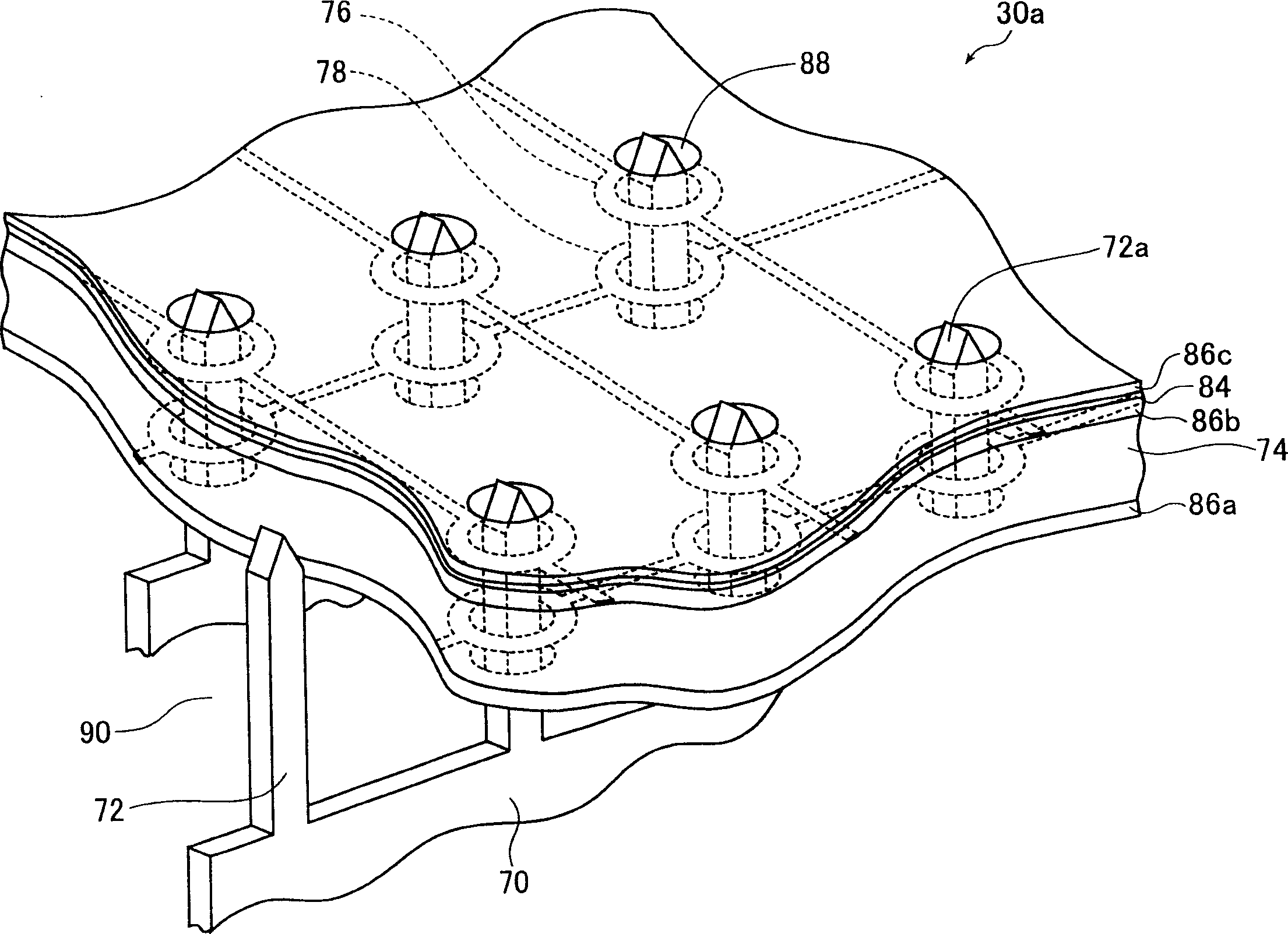

[0036] figure 1 is a schematic configuration diagram showing the general configuration of the first embodiment of the inkjet recording apparatus according to the present invention.

[0037] By using the image forming device, an image composed of ink particles (pigment particles) is formed on the recording medium P conveyed by the conveying device by ejecting ink droplets of four colors according to the input image data, and aligned on the recording medium P. The image composed of the formed ink particles is fixed (fixed or fixed), figure 1 The illustrated electrostatic inkjet recording apparatus 10 (hereinafter referred to as "inkjet printer") enables recording of full-color images. In addition, the inkjet printer 10 also collects air containing a large amount of ink solvent vapor from an area near the fixing / conveying device 26 using collecting means, and removes the solvent in the collected air using removing means.

[0038] figure 1 The illustrated inkjet printer 10 is a...

no. 2 example

[0154] Hereinafter, a second embodiment of the inkjet recording apparatus of the present invention will be described.

[0155] Figure 6 The inkjet printer 100 has the same figure 1 The inkjet printer 10 shown in is substantially the same in structure and function. The difference between the inkjet printer 100 and the inkjet printer 10 is: when the image is formed, the recording medium P is not directly powered; an insulating conveyor belt 112 is used; The counter electrode of the electrostatic adsorption device 116 and the static elimination device 117, which each use a conductive roller; a certain preheating device 118 is arranged between the static removal device 117 and the fixing / transfer device 26; and the removal cover 40 and In addition to the delivery pipe 42 as a collection device for solvent-containing air, a blower device 119 is also provided. In the following description, elements of the same structure as those of the inkjet printer 10 are assigned the same ref...

no. 3 example

[0175] A third embodiment of the ink jet recording apparatus of the present invention will be described below.

[0176] Figure 7 The illustrated inkjet printer 120 includes a recording medium storage cassette 122 that can be inserted into and removed from a housing 121 . As a device for conveying the recording medium P, the inkjet printer 120 includes: a pick-up roller 124; a pair of feed rollers 126; a dust removal device 128; rollers 130a, 130b, and 130c; a conveyor belt 132; ; a separation or peeling device 140 ; a fixing device 142 ; and a discharge roller pair 144 . With this structure, the recording medium P stored in the paper storage cassette 122 is conveyed to each processing step, and then output on the paper output pallet 146 .

[0177] In addition, as an image forming device, the inkjet printer 120 includes: a platen 148; an inkjet head 150; an ink circulation system 152; an inkjet head driver 154; a recording medium position detecting device 156; Position co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com