High-speed in-line electro-optics testing method and system for defects on chip

An electro-optical detection and defect technology, applied in the field of methods and systems, can solve problems such as time spent on detecting wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

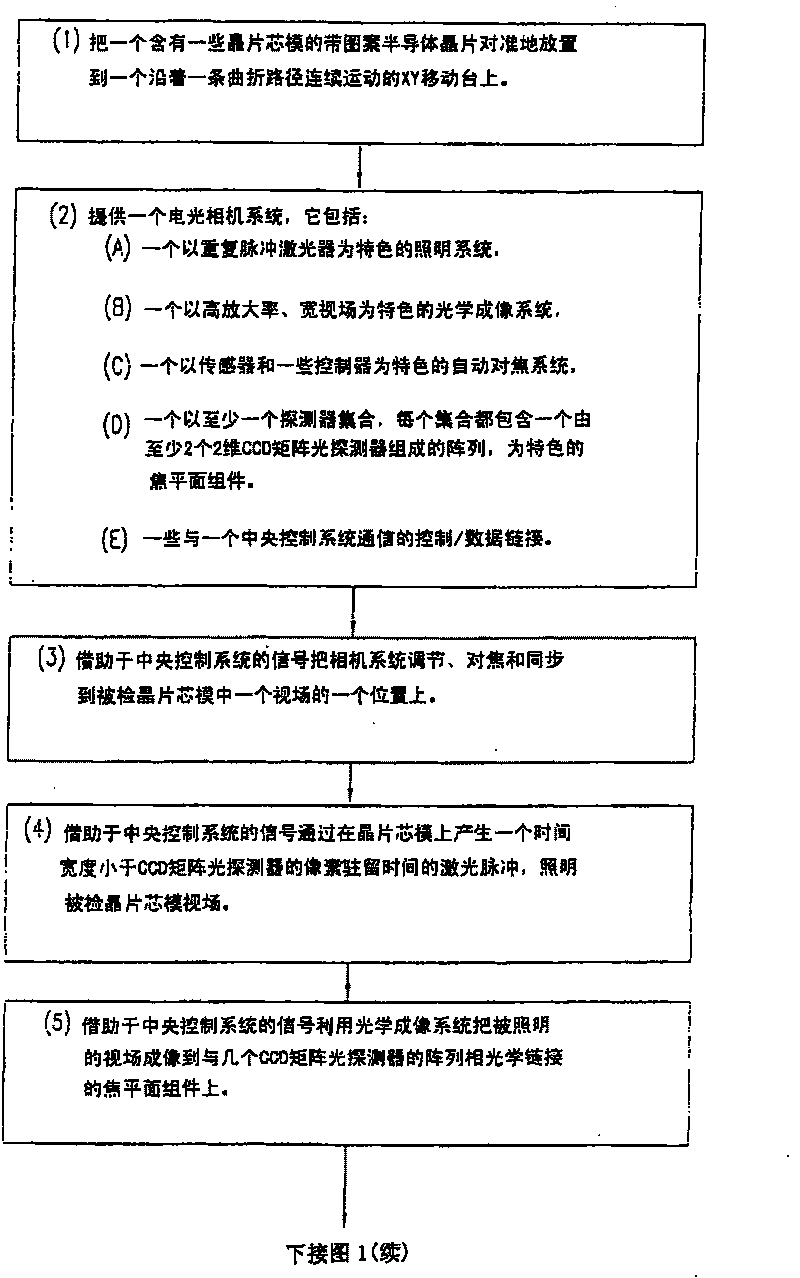

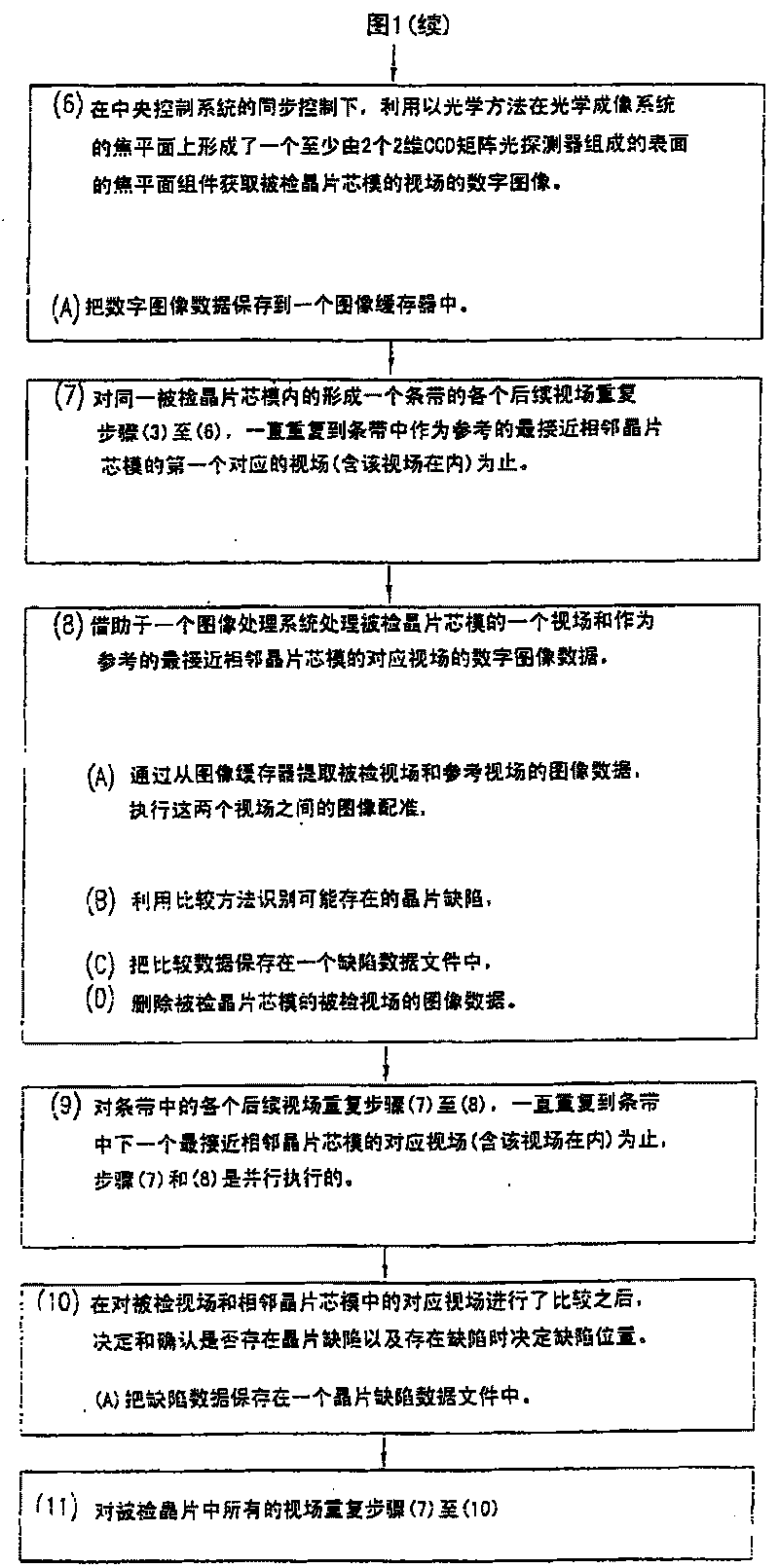

Method used

Image

Examples

Embodiment Construction

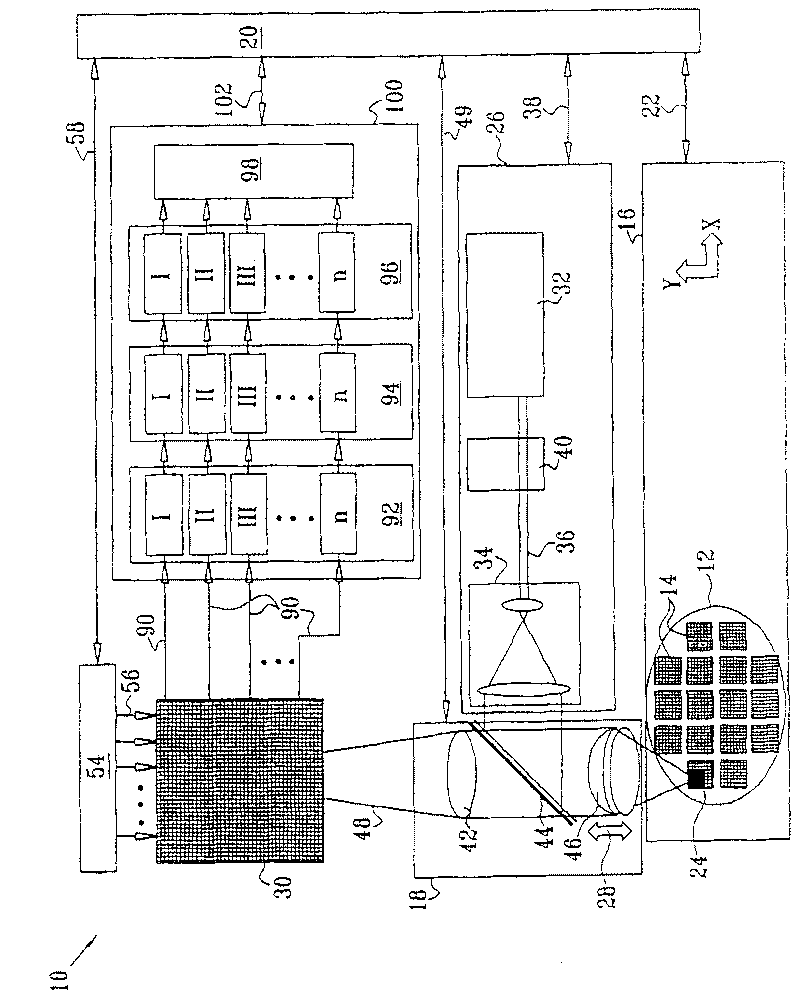

[0046] The present invention advantageously includes methods and systems for rapid in-line electro-optic detection of wafer defects.

[0047] The method and system for rapid on-line electro-optic detection of wafer defects of the present invention introduce a unique combination of a new imaging system and an illumination system, wherein the new imaging system is characterized by an optical method formed on a surface composed of several 2-dimensional matrix photodetectors. The photodetector surface on the focal plane formed by the composed array is used to acquire high resolution, high pixel density and large field of view images of the wafer die in synchronization with the illumination system; the illumination system is characterized by the use of a repeating Short pulses of light from a pulsed laser illuminate the wafer die. The width of the laser pulse is much shorter than the dwell time of the image pixel, where the pixel dwell time refers to the time when a point on the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com