Waveform monitoring device and method for monitoring waveform

A monitoring device and waveform technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of not showing the reference waveform, not knowing the difference and change of unqualified parts and unqualified degrees, and reduce the burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

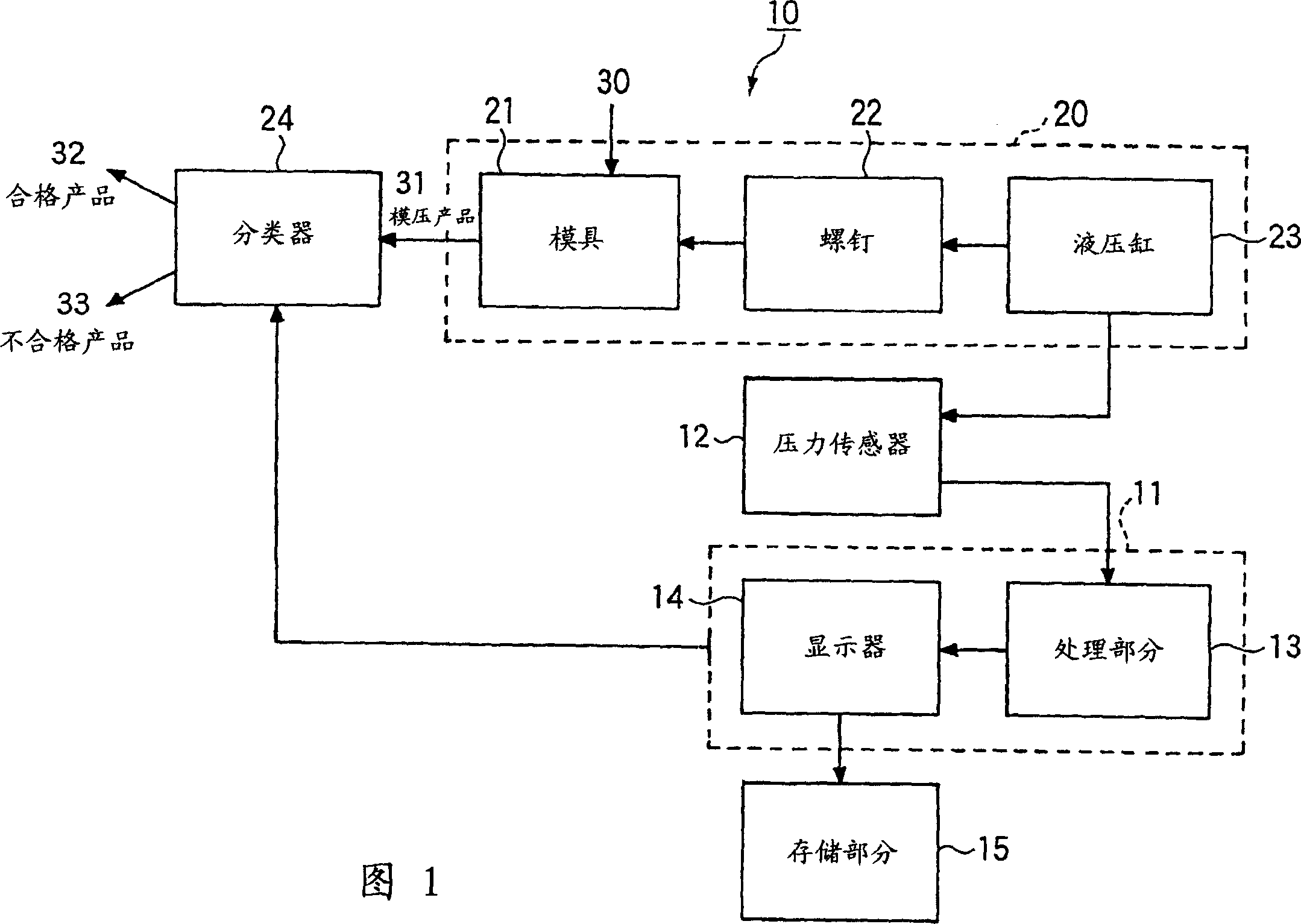

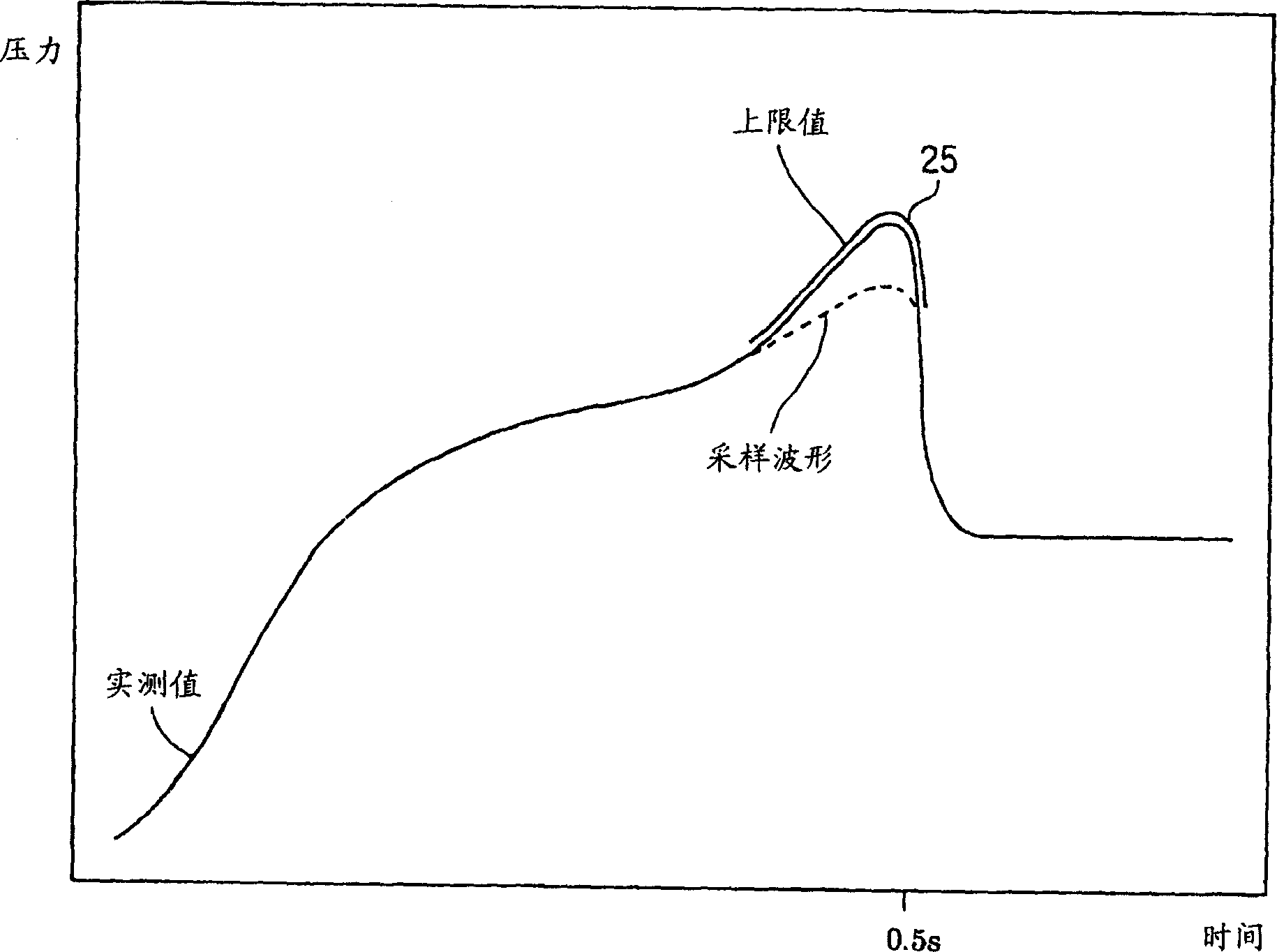

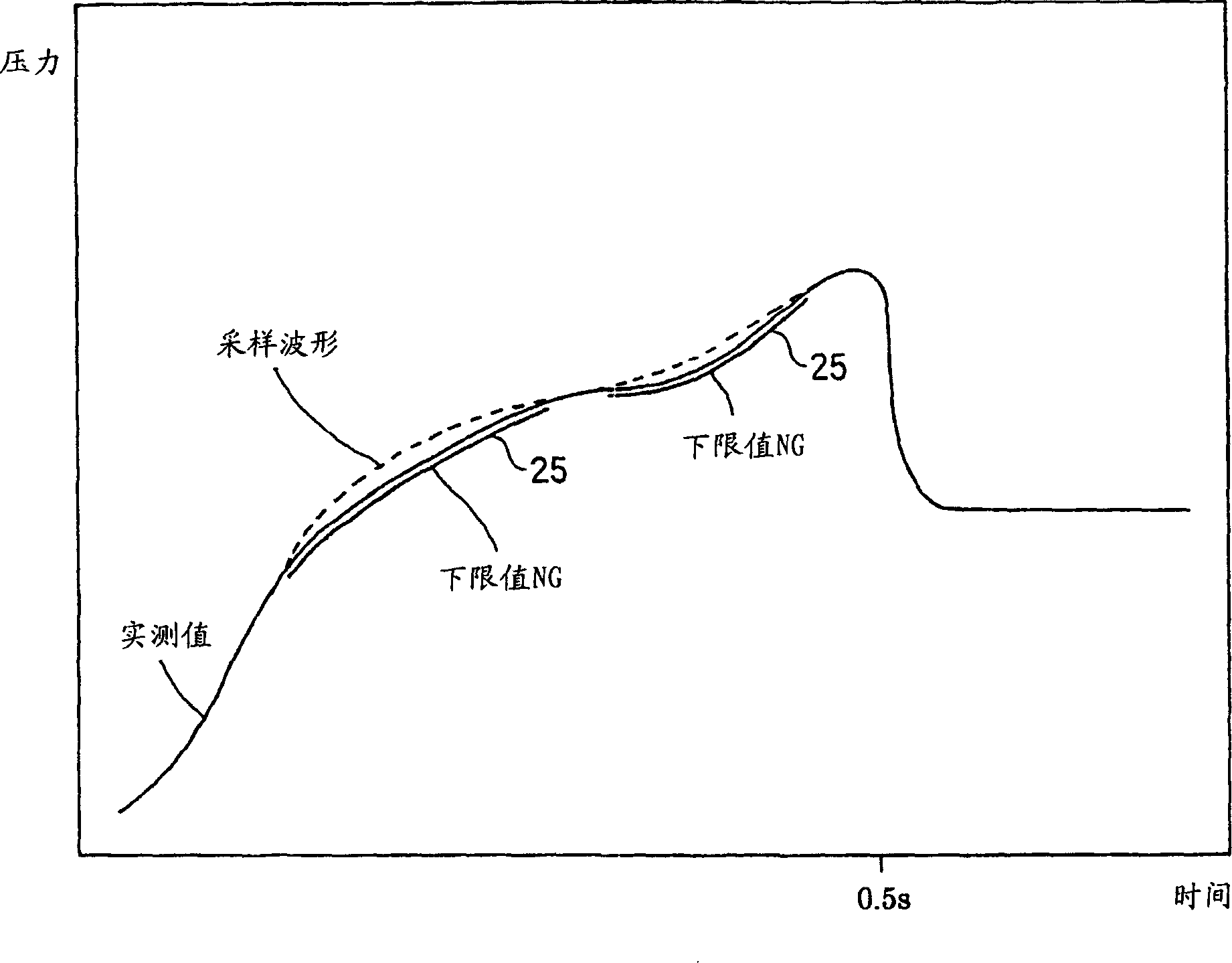

[0044] Embodiments of the simple waveform monitoring device according to the present invention will be described in detail with reference to accompanying drawings 1-3.

[0045] As shown in FIG. 1 , a simple waveform monitoring device 10 according to an embodiment of the present invention is combined with an injection molding tool 20 including a mold 21 , screws 22 , and a hydraulic cylinder 23 , and a classifier 24 . The simple waveform monitoring device 10 generally includes a pressure sensor 12 , a determination unit 11 and a storage portion 15 , wherein the determination unit 11 includes a processing portion 13 and a display 14 .

[0046] In the injection molding process, after the material (molding material) 30 is filled in the hydraulic cylinder (heating cylinder) 23, the injection molding tool 20 is pushed towards the screw head (not shown) and the ring valve (not shown) via the rotation of the screw 22 shown), the screw 22 engages with the screw head.

[0047] Next, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com