Chemical Supply device and method thereof

A supply device and liquid medicine technology, applied to the surface coating liquid device, pump device, separation method, etc., can solve the problems of reduced discharge accuracy, unstable liquid medicine discharge, and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

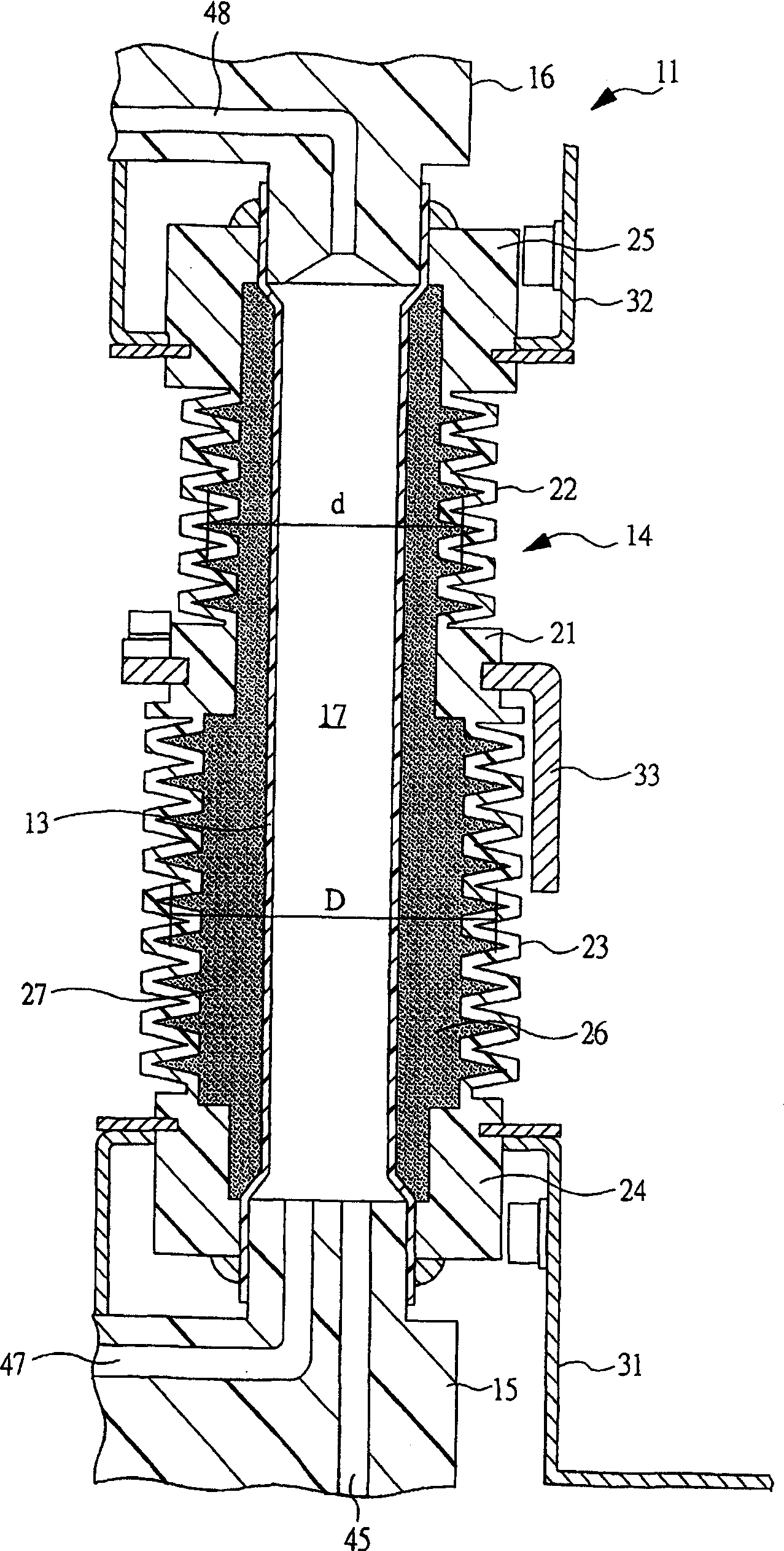

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

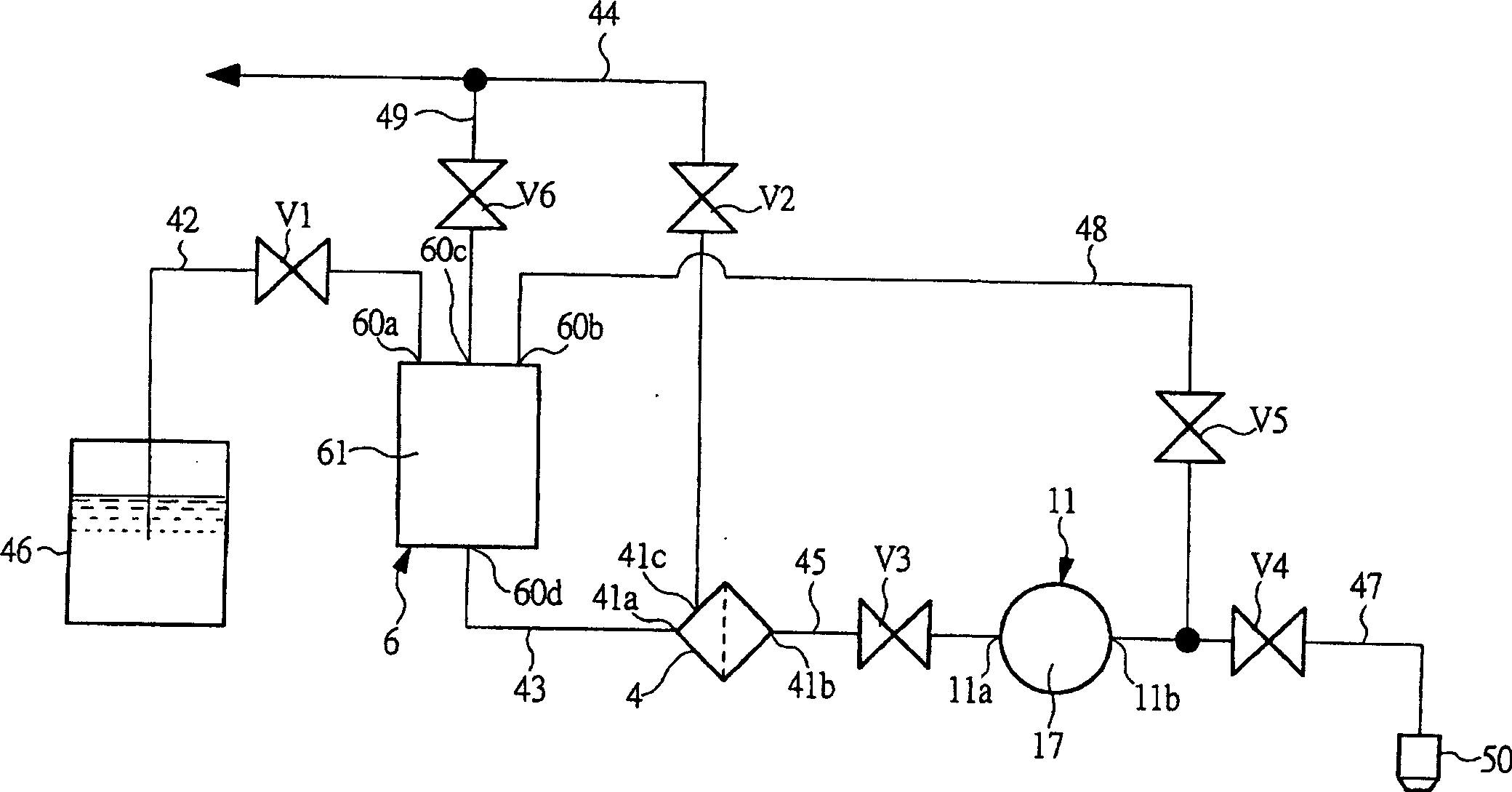

[0018] figure 1 It is a liquid circuit diagram showing the outline of a chemical liquid supply device as one embodiment of the present invention. Such as figure 1 As shown, the buffer tank part 6 of the liquid medicine supply device is provided with a liquid storage chamber 61 inside, and a liquid inflow port 60a connected to the liquid introduction flow path 42 is formed on the top wall, and a liquid inlet 60a connected to the return flow path 48 is formed. The inflow port 60b, the exhaust port 60c connected to the exhaust channel 49, and the liquid discharge port 60d connected to the communication channel 43 are formed on the bottom wall.

[0019] On the liquid inlet 60a of the buffer tank part 6, one end of the liquid introduction flow path 42 is connected. The liquid introduction flow path 42 is provided with an introduction valve V1 for opening and clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com