Etching agent composition and method for producing reflective plate using the same etching liquid composition

A composition and etching solution technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of cumbersome etching process, difficulty in forming highly fine patterns, uneconomical, etc., and achieve the purpose of suppressing the amount of side corrosion, easy operation, The effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

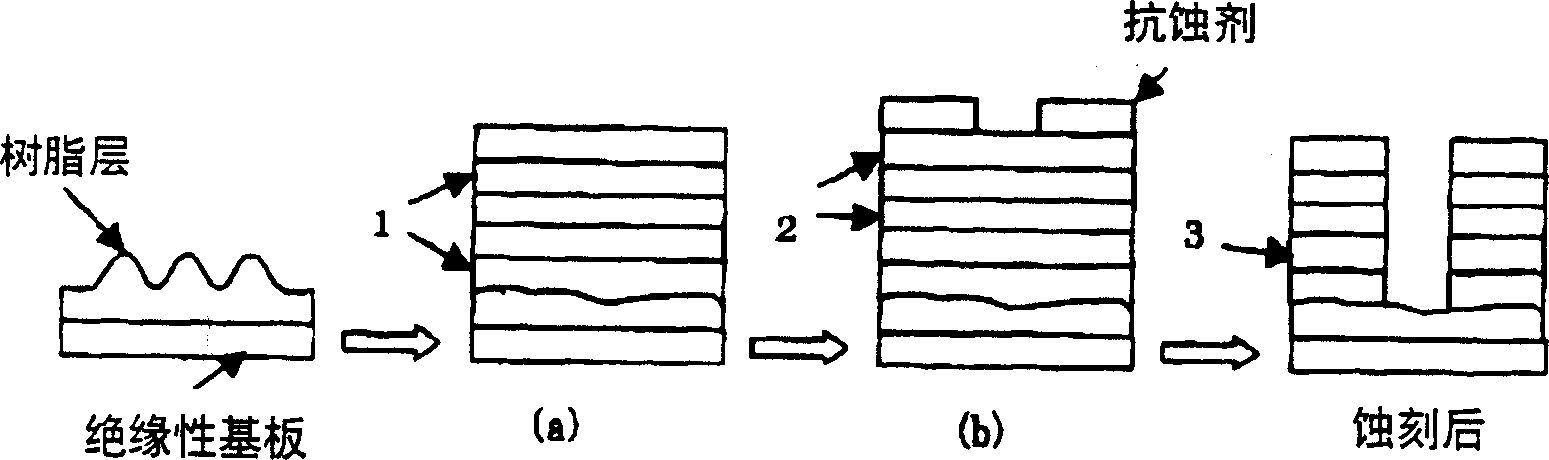

[0034] Such as figure 1 As shown in (a), a resin layer as a light scattering layer is formed on an insulating substrate made of glass or the like by a coating method. On top of it, SiO with a refractive index of 1.7 is formed by sputtering 2 Film / ITO film with a refractive index of 2.1 / SiO 2The reflective layer composed of film / silver alloy / ITO film is made into the substrate.

[0035] Conventionally, a metal film (aluminum, etc.) capable of reflecting light was formed on an insulating substrate, but since it has no unevenness, it completely reflects light like a mirror, making it difficult to see the actual display on the display. To prevent this phenomenon, such as figure 1 The above-mentioned resin layer is formed on an insulating substrate, and a moderate light-scattering effect is produced by providing a concavo-convex shape, so that the display of the display can be easily observed.

[0036] Subsequently, if figure 1 As shown in (b), the board|substrate was patterne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com