Wear-resistant sliding member

A sliding part, external sliding technology, applied in the direction of engine components, machines/engines, coatings, etc., can solve problems such as attack, cylinder liner wear, etc., achieve low attack, prolong engine life, excellent wear resistance and friction resistance The effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

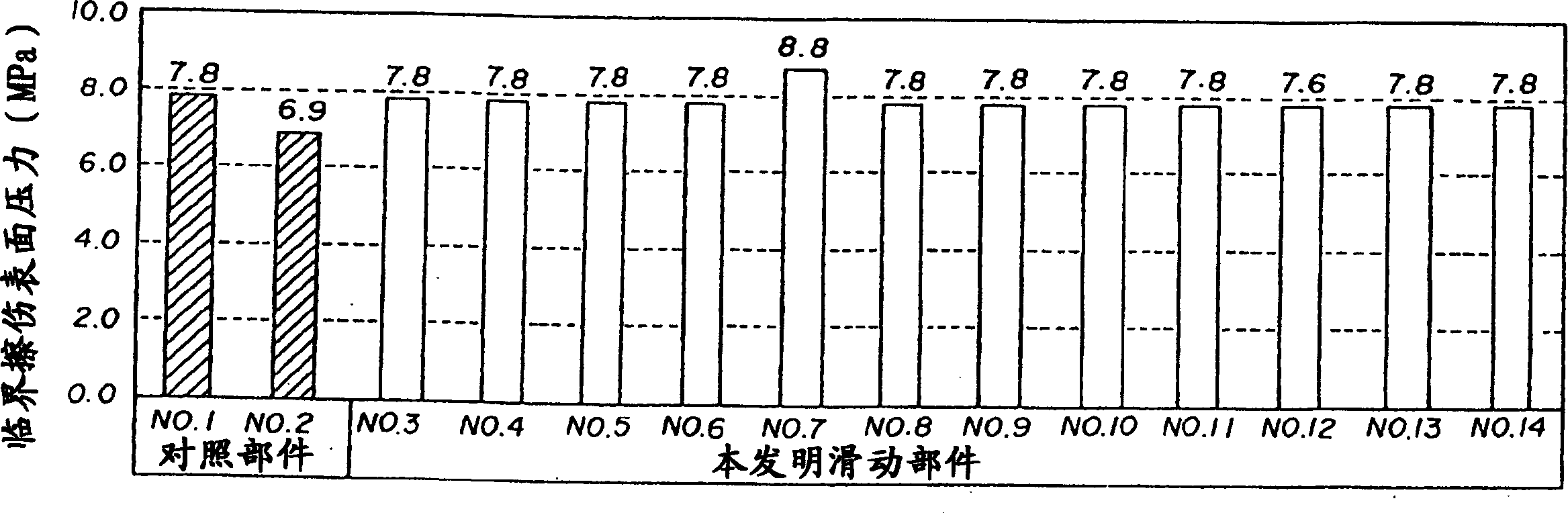

[0020] Now, embodiments of the sliding member according to the present invention will be further described in conjunction with various tests conducted for comparison with other sliding members.

[0021] 14 types of 300 μm thick coatings were formed on the same cast iron segment used for piston rings (as the base material), and 14 samples were prepared, of which two samples 1 and 2 were controls or corresponded to the preceding Other sliding parts described in the references, 12 samples 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 and 14 are according to the invention or correspond to the respective embodiments. The coatings were obtained by plasma spraying various powder mixtures whose compositions are shown in Table 1.

[0022] Table 1

[0023] Sample number Remarks Composition of powder mixture (% (mass))

[0024] Mo Ni-Cr Alloy Ceramic Solid Lubricant

[0025] 1 Control 45 20 35(CrC)

[0026] 2 Control 65 30 5(CrC)

[0027] 3 Example of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com