Razor system

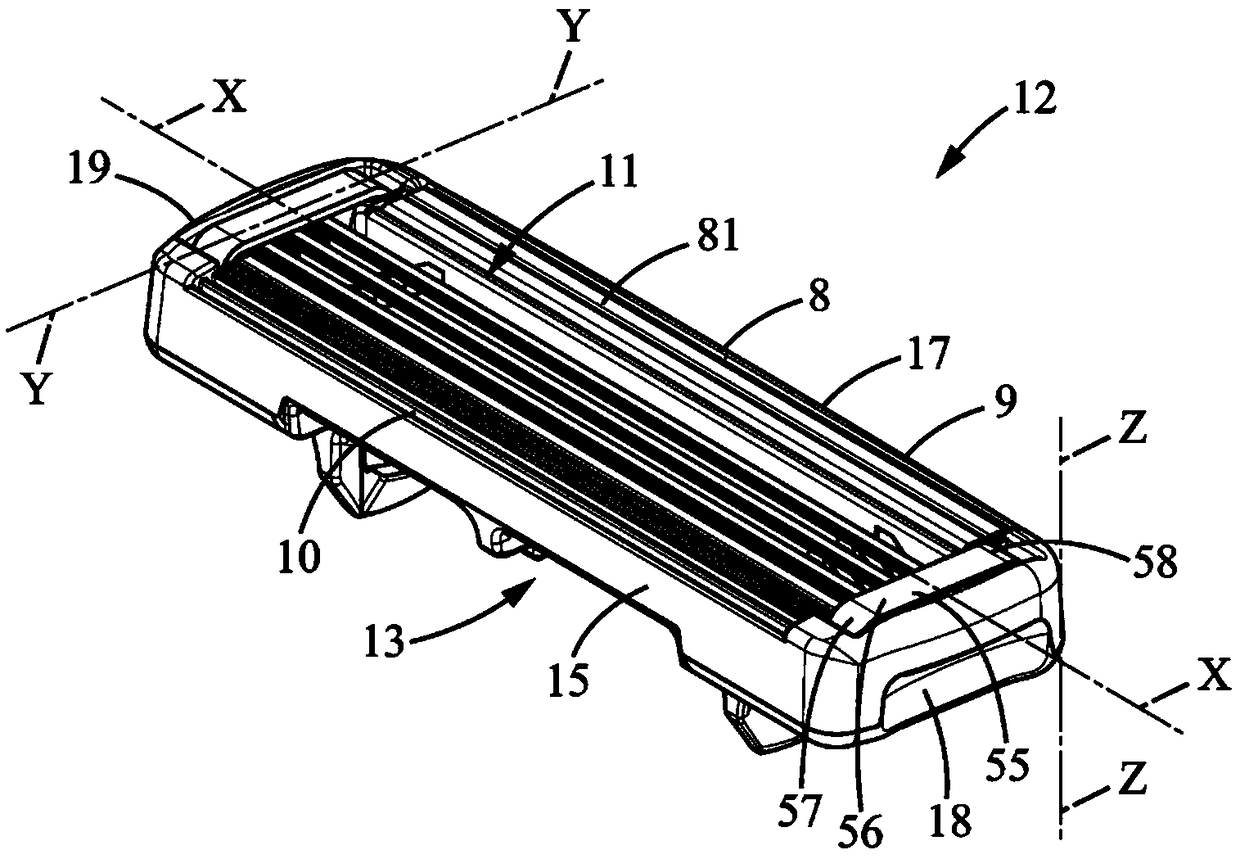

A technology for shaving boxes and knife holders, which is applied in the fields of unique and special shapes, manufacturing cutting parts of shaving boxes, and knife holders, which can solve the problems of reducing the cleanability of shaving heads, improve shaving performance, and manufacture Fast method, less nicks and cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be understood that the concepts are not limited in their application to the details of construction and embodiments of components set forth in the following description or illustrated in the drawings. The drawings and written description are provided to teach those skilled in the art to make and use the inventions sought under patent protection.

[0021] The concept is capable of other embodiments and of being practiced and carried out in various ways. Those skilled in the art will understand that the development of an actual business embodiment incorporating aspects of the present concept requires a great deal of practice - professional decision-making in order to achieve the ultimate goals of the business embodiment developer. Such efforts, while potentially complex and time-consuming, are no less than the routine undertaking of those of ordinary skill in the art having the benefit of this disclosure.

[0022] The phraseology and terminology used herein are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com