Phosphor for vacuum ultravilet ray-excited light-emitting element

A technology of vacuum ultraviolet rays and light-emitting elements, which is applied in the directions of light-emitting materials, fluorescent layers, gas discharge electrodes, etc., and can solve the problems such as the decline of the brightness of phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0044] The present invention is explained in more detail with the following examples, which should not be construed as limiting the invention in any way.

[0045] The composition of the phosphor was analyzed in the following manner. A sample of the phosphor was taken out and melted by alkali fusion with sodium carbonate and boric acid as fluxes. Water and hydrochloric acid are added to the molten sample to obtain a solution. The solution was analyzed using inductively coupled plasma atomic emission spectrometry, and the target element was quantitatively determined.

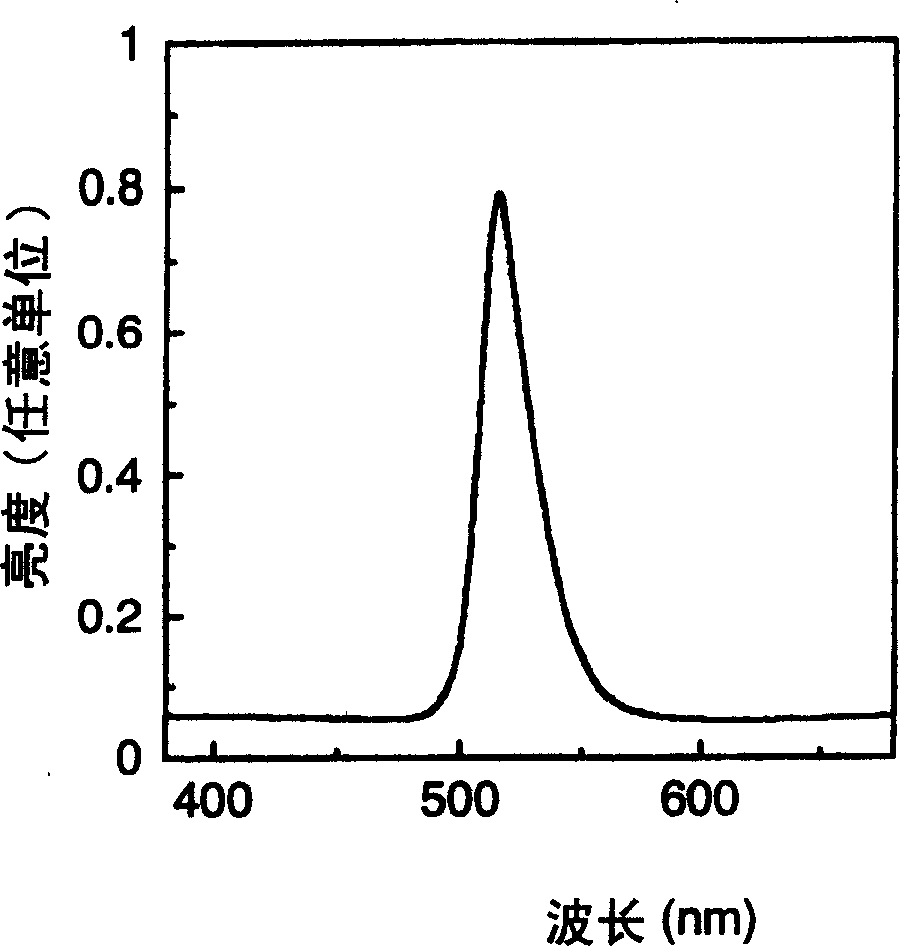

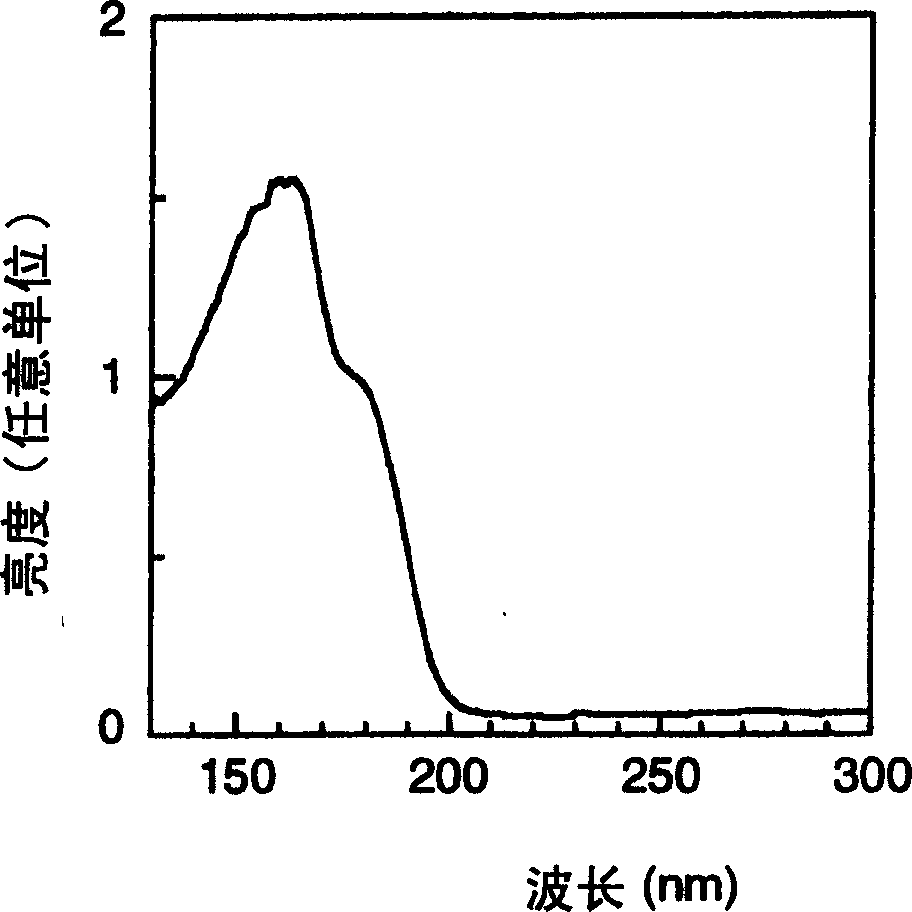

[0046] The brightness measurement of the phosphor was performed in the following manner. The phosphor is placed in a vacuum maintained at 6.7Pa (5×10 -2 torr) or lower, and measured by vacuum ultraviolet ray irradiation using a lamp (model H0012 produced by Ushio Inc.) that excites atoms at 146 nm. Also, the phosphor was heat-treated at 500°C for 30 minutes in air, and then the luminance was measured in the sa...

example 1

[0048] Production of LaMg 0.95 mn 0.05 Al 11 o 19 (comply with the compound of molecular formula (I): M 1 1-a-b-c-d m 2 a m 3 b m 4 1-e m 5 11-f m 6 c+d+e+f o 19-(b+c+f) / 2 , where M 1 It's La, M 4 is Mg, M 5 is Al, M 6 is Mn, a=0, b=0, c=0, d=0, e=0.05, f=0):

[0049] Lanthanum oxide (purity: 99.99%; manufactured by Shin-Etsu Chemical Co., Ltd.), basic magnesium carbonate (purity: 99% or more; manufactured by Kyowa Chemical Industry Co., Ltd.), aluminum hydroxide (purity: 99% or higher; produced by Sumitomo Chemical Co., Ltd.) and manganese carbonate (purity: 99.9%; produced by Wako Pure Chemical Industries, Ltd.) according to La 2 o 3 :(MgCO 3 ) 4 Mg(OH) 2 ·5H 2 O:Al 2 o 3 : MnCO 3 = 2.13: 1.21: 7.33: 0.075 Weighing so that the molar ratio La: Mg: Al: Mn = 1.0: 0.95: 11.0: 0.05, these materials were mixed with isopropanol as a solvent using a wet ball mill for 4 hours. The solvent in the slurry was removed with an evaporator, and the slurry was dr...

example 2

[0051] Production La 0.9 Y 0.1 Mg 0.95 mn 0.05 Al 11 o 19 (comply with the compound of molecular formula (I): M 1 1-a-b-c-d m 2 a m 3 b m 4 1-e m 5 11-f m 6 c+d+e+f o 19-(b+c+f) / 2 , where M 1 It's La 0.9 Y0.1 ,M 4 is Mg, M 5 is Al, M 6 is Mn, a=0, b=0, c=0, d=0, e=0.05, f=0):

[0052] The same procedure as Example 1 was carried out except that lanthanum oxide (purity: 99.99%; produced by Shin-Etsu Chemical Co., Ltd.), yttrium oxide (purity: 99.99%; produced by Shin-Etsu Chemical Co., Ltd.), Basic magnesium carbonate (purity: 99% or more; produced by Kyowa Chemical Industry Co., Ltd.), aluminum hydroxide (purity: 99% or more; produced by Sumitomo Chemical Co., Ltd.), and manganese carbonate (purity: 99.9% %; Wako Pure Chemical Industries, Ltd. production) according to La 2 o 3 : Y 2 o 3 :(MgCO 3 ) 4 Mg(OH) 2 ·5H 2 O:Al 2 o 3 : MnCO 3 =1.93:0.15:1.21:7.37:0.076 Weighed so that the molar ratio La:Y:Mg:Al:Mn=0.9:0.1:0.95:11.0:0.05. Under vacuum u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com