Melt polycarbonate catalyst system

A polycarbonate, melt polymerization technology, applied in the field of polycarbonate preparation, can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

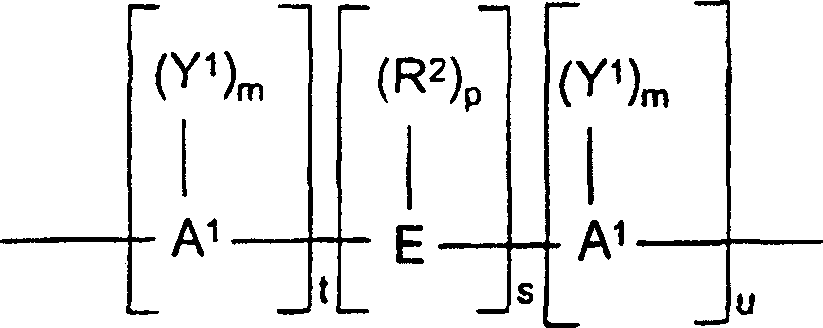

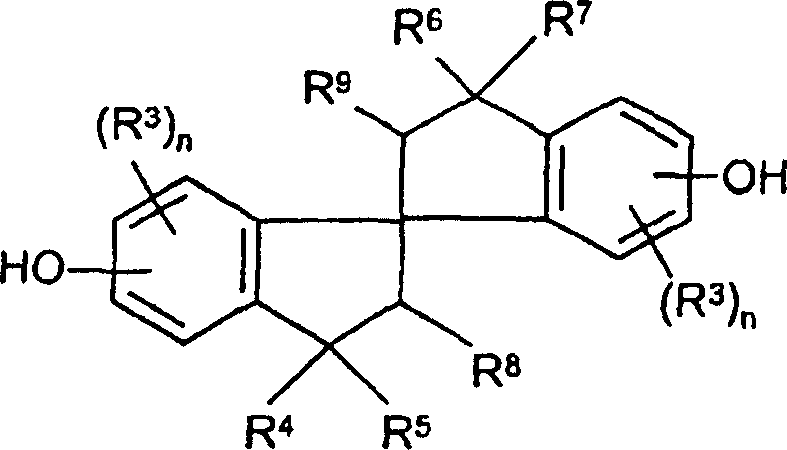

[0011] The invention provides a kind of polycarbonate preparation method, this method comprises under melt polymerization reaction condition in molecular formula A x + MF 6 -x contacting a diaryloxy compound and a dihydric phenol compound in the presence of a compound of , optionally in the presence of a cocatalyst selected from tetraalkylammonium and tetraalkylphosphonium salts,

[0012] where A is an alkali metal or an alkaline earth metal;

[0013] M is a transition metal of group IVA or VA, or M is a p-block metal of IIIB, IVB or VB;

[0014] x is 1, 2 or 3.

[0015] In a preferred embodiment, A is selected from sodium, potassium, cesium, lithium, barium or calcium. In a further preferred embodiment, M is a metal cation selected from silicon, tin, germanium, zirconium, strontium, aluminum, niobium and titanium.

[0016] Particularly preferred catalysts include Na 2 SiF 6 、Na 2 SnF 6 、Cs 2 SiF 6 、Cs 2 SiF 6 、K 2 TiF 6 、Na 2 GeF 6 、Na 2 ZrF 6 、Na 2 SbF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com