Method for producing tunable optical fiber attenuator

A manufacturing method and technology of an optical attenuator, which is applied in the field of optical communication and can solve problems such as difficulty in making attenuators and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

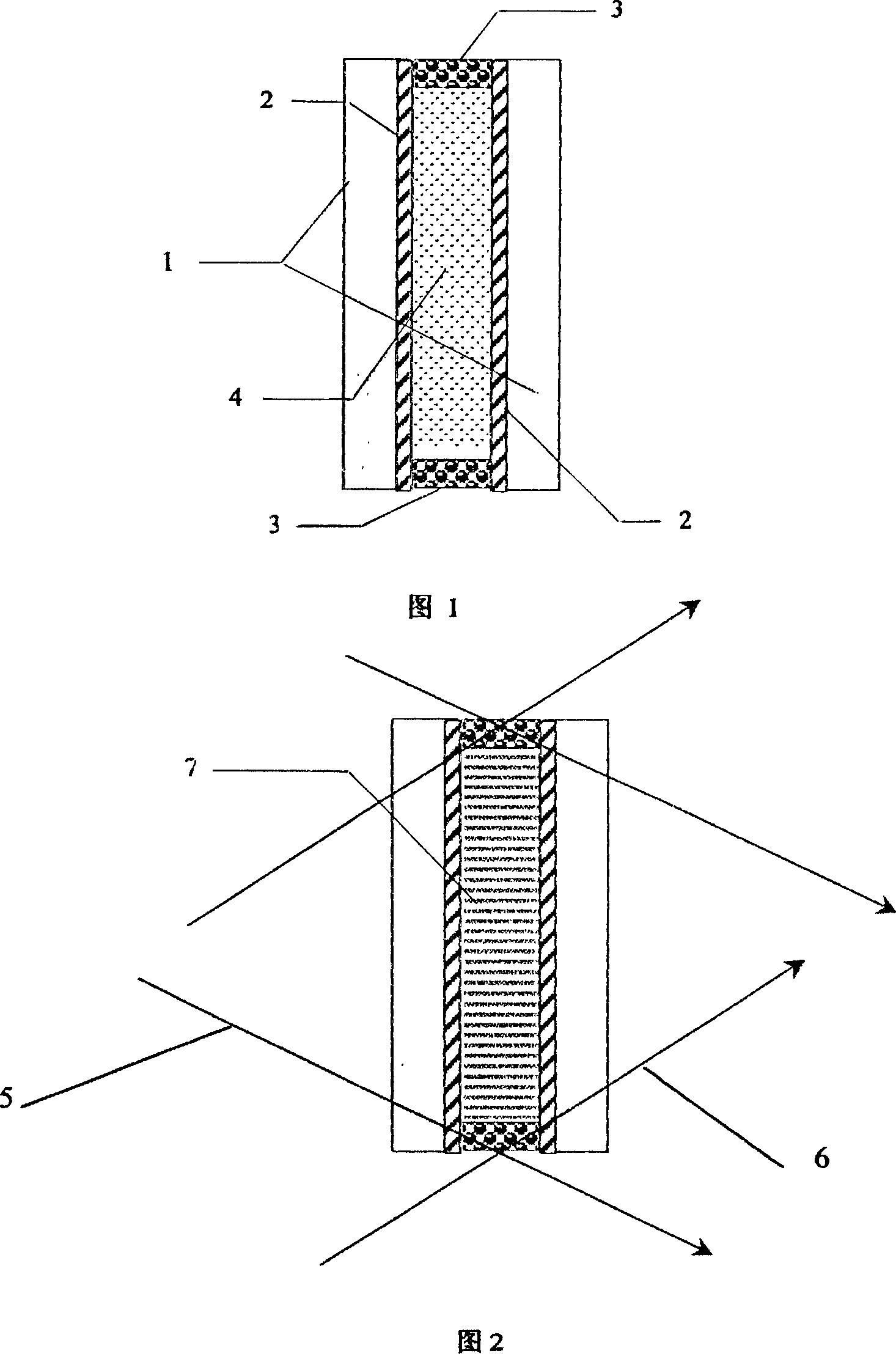

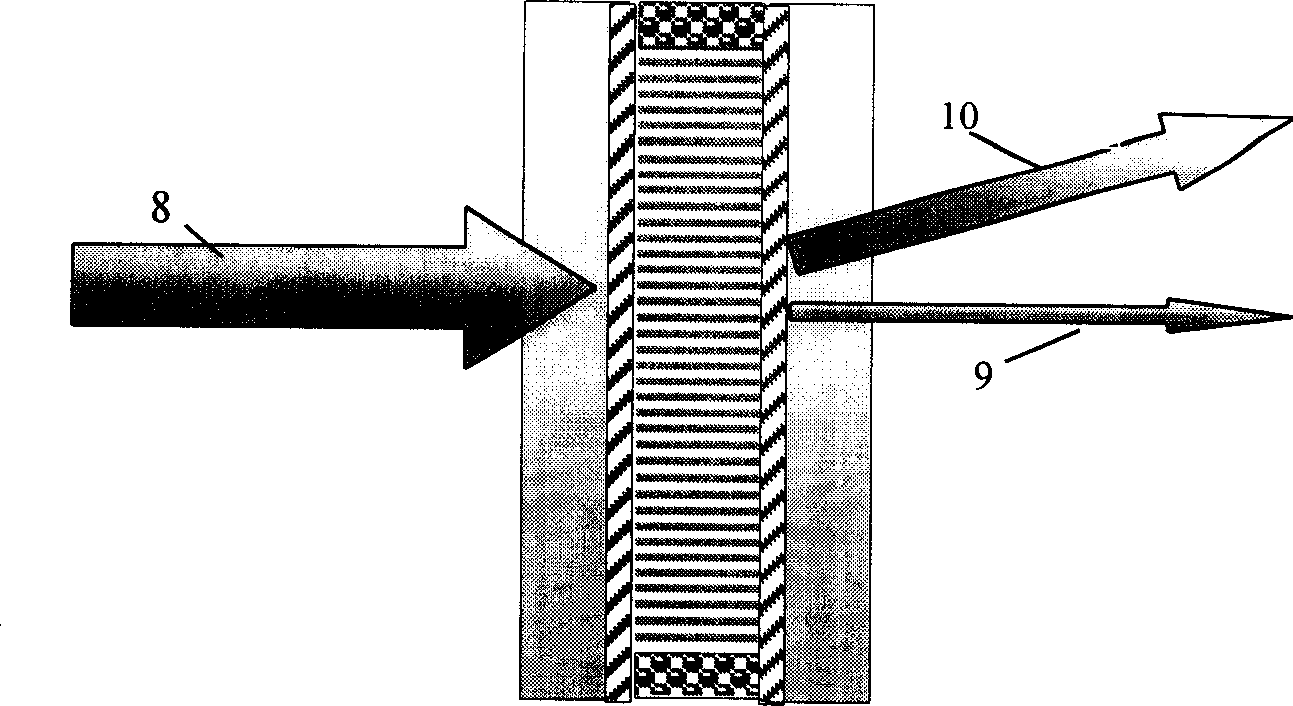

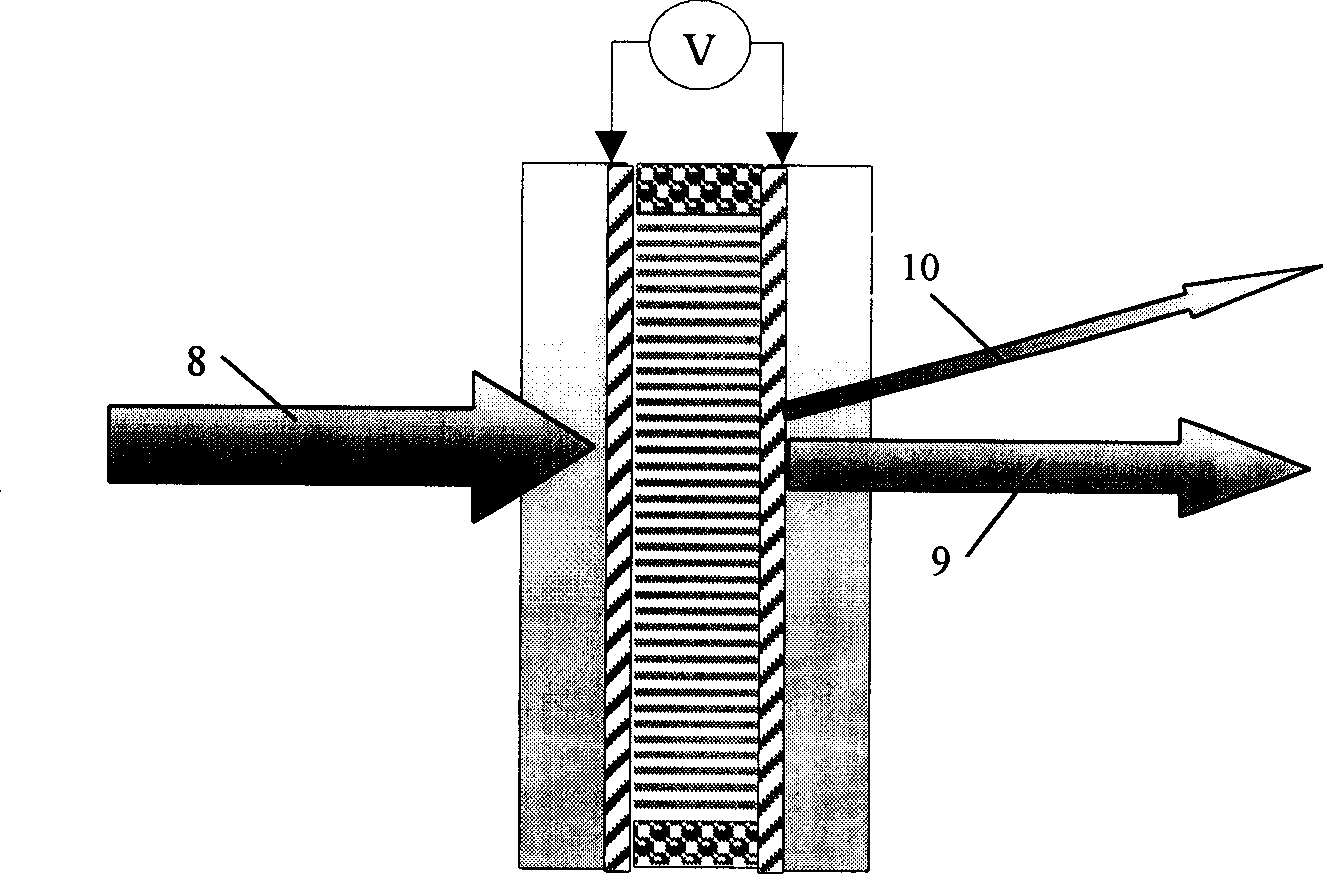

[0014] The implementation steps of the method are as follows: 1. Prepare a liquid crystal grating element, as shown in FIG. 1 , which includes two glass substrates 1 coated with an ITO conductive layer 2 , and the glass substrate 1 is filled with 5-10 μ photocuring high A recording layer composed of a mixture of molecular prepolymerized material and liquid crystal 4 (polymer-dispersed liquid crystal material, namely PDLC solution), and spacers 3 are placed at both ends of the PDLC solution; 2. Design a holographic optical path by laser holography, and establish a As shown in Figure 2, 5 is the coherent laser 1, 6 is the coherent laser 2, and 7 is the interference fringe generated; 3. Apply an electric field on the liquid crystal grating, and the electric field acts on it. The molecular orientation of the liquid crystal has a tendency to gradually unify from the disordered state to the direction of the electric field. The magnitude of the applied electric field directly affects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com