Method for reducing produced bacterial mud and mixture

A technology for mixtures and bacterial sludge, applied in chemical instruments and methods, special compound water treatment, bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

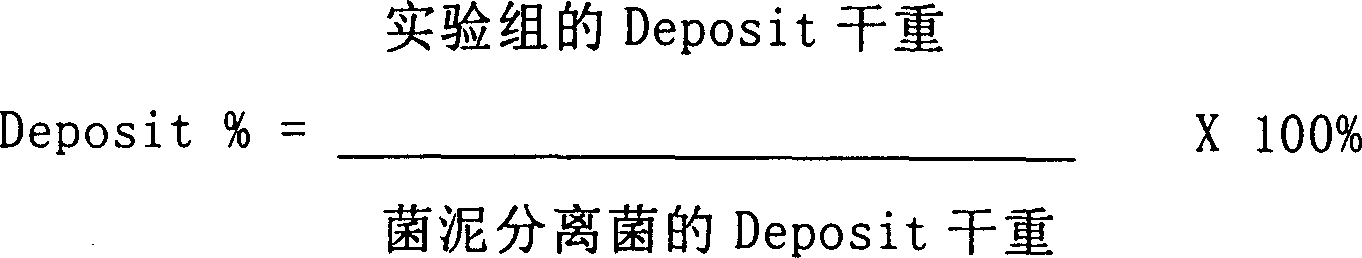

[0014] Example 1: Test of the influence of antagonistic bacteria and dispersants on the formation of deposits

[0015] Experimental procedure

[0016] Centrifuge 1mL of each strain isolated from the sludge cultured in NB liquid culture medium for 21-24 hours at 15000rpm for 1min, remove the supernatant, add 1mL of sterile water to resuspend all the test strains, and then inoculate into 100mL Erlenmeyer flask with sterilized white water and 3g LBKP slurry. Afterwards, different dispersants were added to the above treatment respectively, and cultured in a 40°C, 70rpm shaking incubator. After 3hrs of fully mixed culture, 3mL of the antagonistic bacteria C5 Streptomyces bikiniensis (Streptomyces bikiniensis) that had been cultured for 24h were added. Bacterial liquid, about 107 / ml, and cultured in 40°C, 70rpm shaking incubator, observed and recorded the amount of precipitation after 7 days.

[0017] The whole experiment was divided into six treatments,

[0018] There are two c...

Embodiment 2

[0048] Embodiment two: Follow-up test of regular addition of antagonistic antibiotics

[0049] Experimental procedure

[0050]Centrifuge 1 mL of each strain isolated from the sludge cultured in NB liquid culture medium for 21-24 hours at 15,000 rpm for 1 min, remove the supernatant, add 1 mL of sterile water to resuspend all the test strains, and then inoculate into 100 mL of the sterilized Bacterial white water and 3g LBKP slurry in the conical flask, mix well and culture in 40°C, 70rpm shaking incubator, after 3hr, add 3mL of antagonistic bacteria C5 cultured for 24h, about 107 / ml, Also cultured in a 40°C, 70rpm shaking incubator, observed and recorded the amount of Deposit produced every 7 days, and added antagonistic bacteria C5 again at the same time, observed and recorded the final result after 14 days.

[0051] The whole experiment was divided into four treatments:

[0052] There are two comparison groups:

[0053] 1: A control group that was only inoculated with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com