Method for preparing ethene and propylene

An ethylene and propylene technology, applied in the field of preparation of low-carbon olefins, can solve the problems of difficulty in separation, uneconomical and the like, and achieve the effects of long service life, simple preparation method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

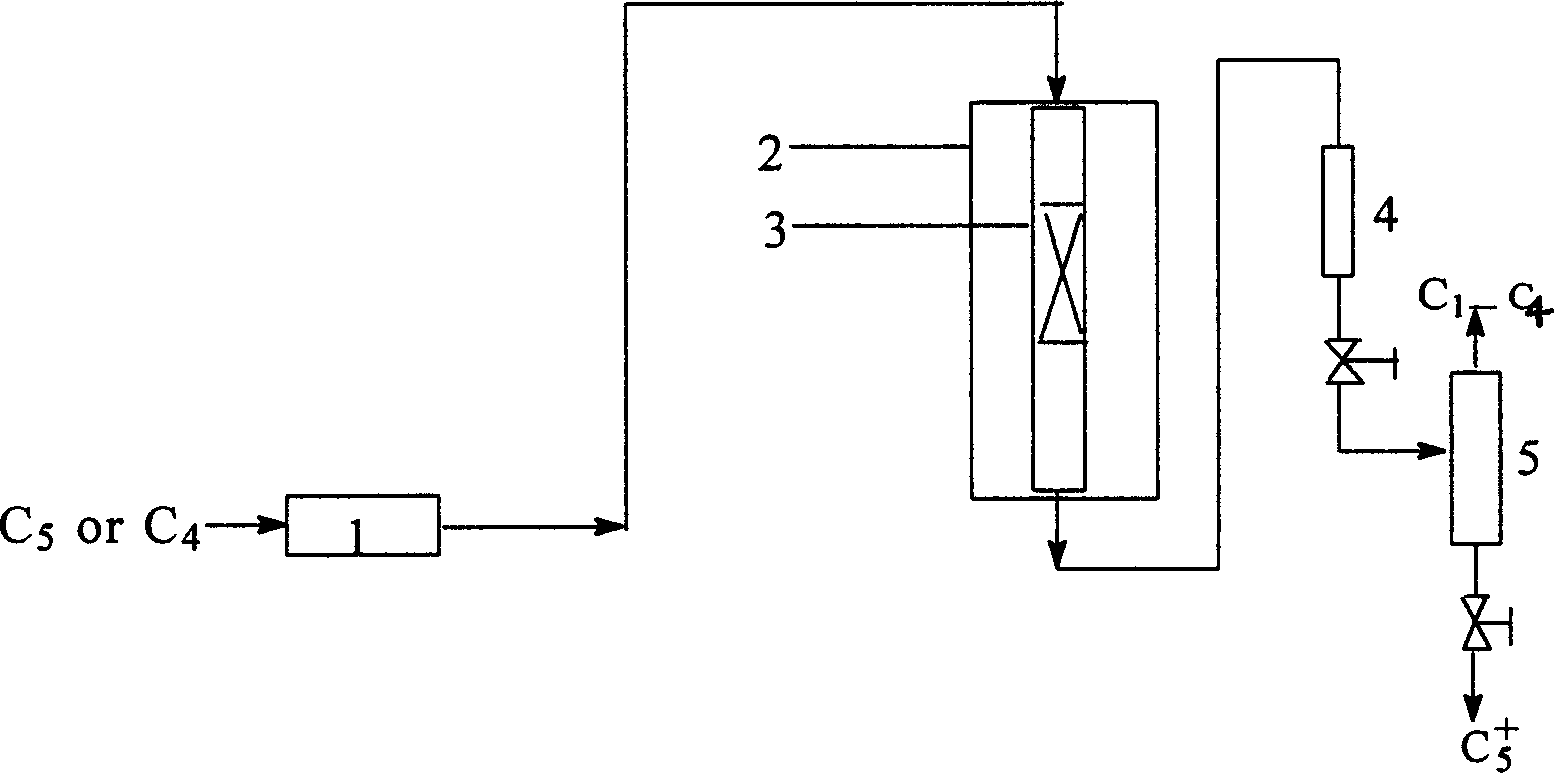

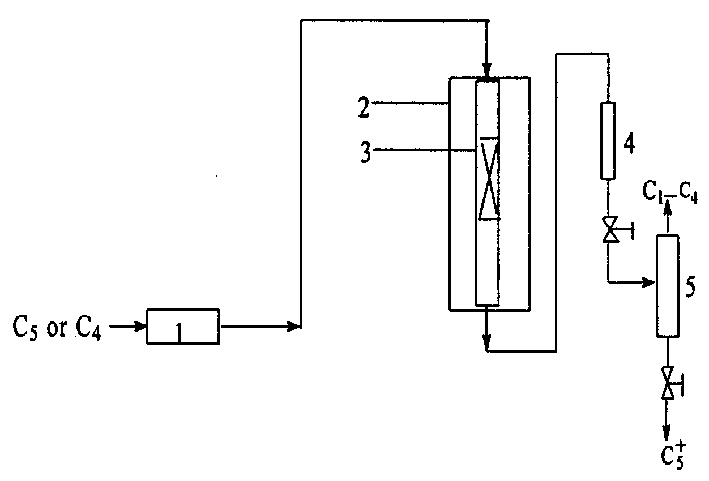

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of catalyst A

[0037] 150g ZRP molecular sieve (provided by Beijing Wanshuyuan Economic and Technological Trade Center, SiO 2 / Al 2 O 3 >200), 75g alumina (provided by Beijing Green Star Special Catalytic Technology Co., Ltd.), and 8g succulent powder; add 120ml of 5% nitric acid after mixing, extrude into 2mm cylindrical shape after mixing, and cut into 2- 3mm; dried at 80°C and 120°C for 10 hours respectively, then calcined at 580°C for 6 hours, taken out and cooled to room temperature; then take 50g of the shaped catalyst with 30ml of 0.3M ammonium molybdate, 0.1M lanthanum nitrate and 0.6M phosphoric acid respectively Immersion in ammonium solution, drying at 80°C and 120°C for 10 hours, calcining at 580°C for 6 hours, and then put into a desiccator for use.

[0038] The catalyst prepared in this way, designated catalyst A, has the following composition: Al 2 O 3 29.2%, ZRP zeolite 58.4%, MoO 3 8.1%, P 2 O 5 3.2%, La 2 O 3 is 1.1%.

Embodiment 2

[0039] Example 2 Preparation of catalyst B

[0040] Example 1 was repeated, changing the amount of alumina to 150 g and the amount of nitric acid to 150 ml. Other operation methods are the same as in Example 1.

[0041] The catalyst prepared in this way, designated catalyst B, has the following composition: Al 2 O 3 43.8%, ZRP zeolite 43.8%, MoO 3 8.1%, P 2 O 5 3.2%, La 2 O 3 is 1.1%.

Embodiment 3

[0042] Example 3 Preparation of catalyst C

[0043] Example 1 was repeated, and 150g of ZRP molecular sieve, 75g of alumina, 10g of calcium carbonate, and 8g of succulent powder were mixed;

[0044] The catalyst prepared in this way, designated Catalyst C, has the following composition: Al 2 O 3 28.5%, ZRP zeolite 57.0%, MoO 3 8.0%, P 2 O 5 3.2%, La 2 O 3 It is 1.2%, and CaO is 2.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com