Integral fungus deodorizing reactor and its operation method

An operation method and reactor technology, applied in the field of integrated fungal deodorization reactors, can solve the problems of hindering mass transfer rate, reducing treatment efficiency, deteriorating the treatment effect of biological filter, etc., achieving simple operation and maintenance, and easy control , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

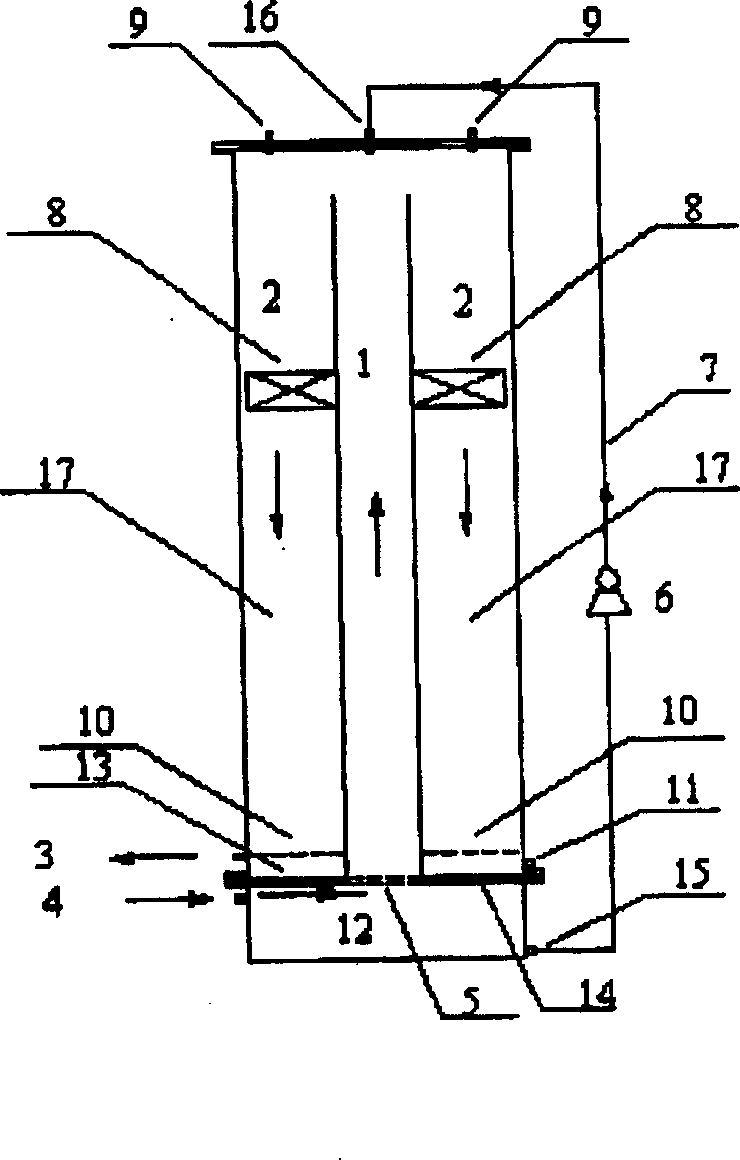

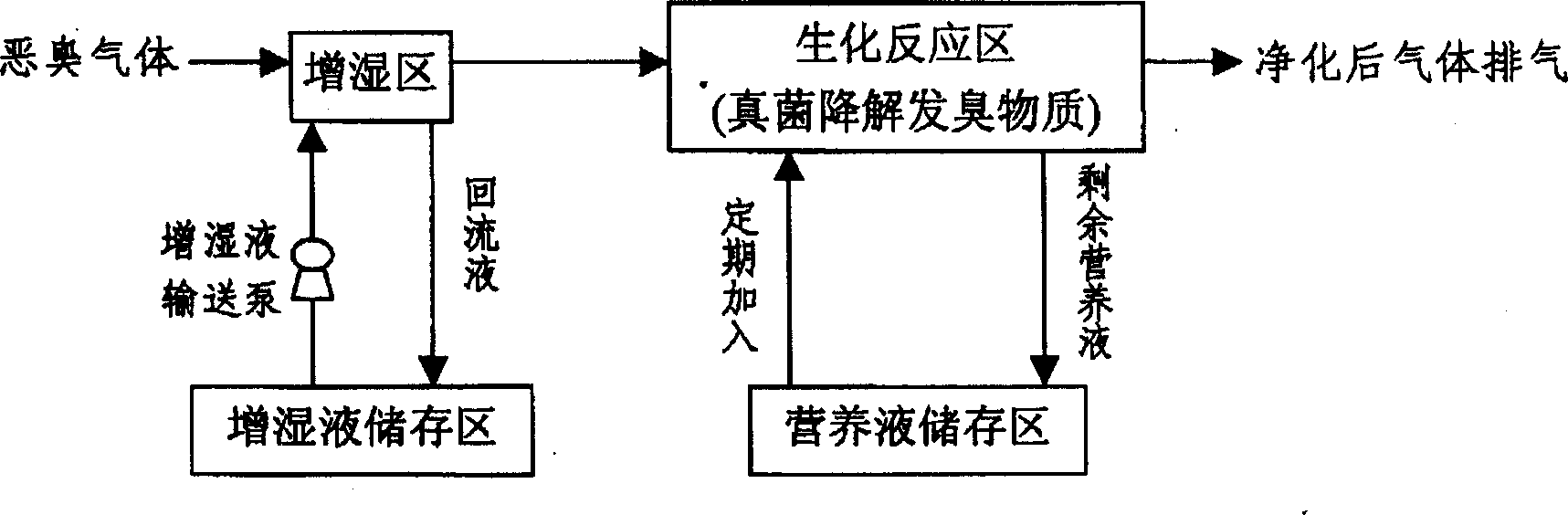

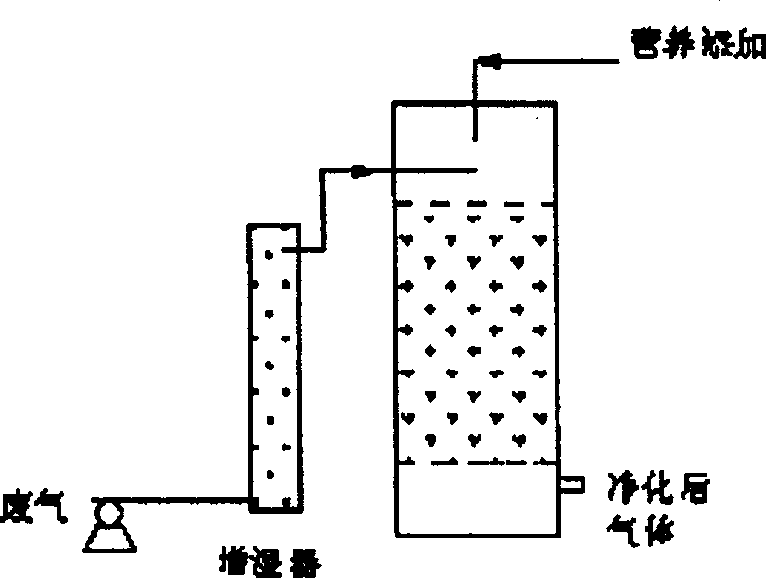

[0046] The integrated fungal deodorization reactor is a cylindrical container, which is divided into a humidification zone 1, a biochemical reaction zone 2, a humidification solution storage zone 12 and a nutrient solution storage zone 13 by partitions.

[0047] The exhaust gas containing ethanethiol enters the upper part of the humidification liquid storage area 12 through the air compressor, and enters the humidification area 1 through the entrance 5 of the humidification area. The humidifying liquid in the humidifying liquid storage area 12 enters the humidifying area 1 through the humidifying liquid delivery pump 6 . The ascending waste gas is mixed with the descending humidifying liquid, and the humidity of the waste gas is adjusted. The humidity-adjusted waste gas enters the biochemical reaction zone 2 directly from the upper outlet of the humidification zone 1 . In the biochemical reaction zone 2, through cultivation, fungi such as Penicillium permanensis, Paecilomyces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com