Resin electrode and electrostatic dust collector using the same

A resin electrode and dust collection device technology, which is applied in the field of electrostatic dust collection devices, can solve the problems of characteristics and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0049] figure 1 It is a schematic diagram which shows an example of the electrostatic dust collector using the resin electrode which concerns on Embodiment 1 of this invention.

[0050] Such as figure 1 As shown, the electrostatic dust collecting device 1 has: an ionization source part 10 as an electrification part composed of a discharge electrode 11 and its counter electrode 12; The connected non-dust-collecting electrode 21 and the dust-collecting electrode 22 oppositely connected to a negative potential constitute a current collecting part 20 as a dust collecting part. Moreover, when the discharge electrode 11 is connected to negative potential, the non-dust collecting electrode 21 is connected to negative potential relatively, and the dust collecting electrode 22 is connected to positive potential relatively.

[0051] In the ionization source unit 10 , a plurality of flat counter electrodes 12 are arranged in parallel and are electrically connected to each other, and th...

Embodiment approach 2

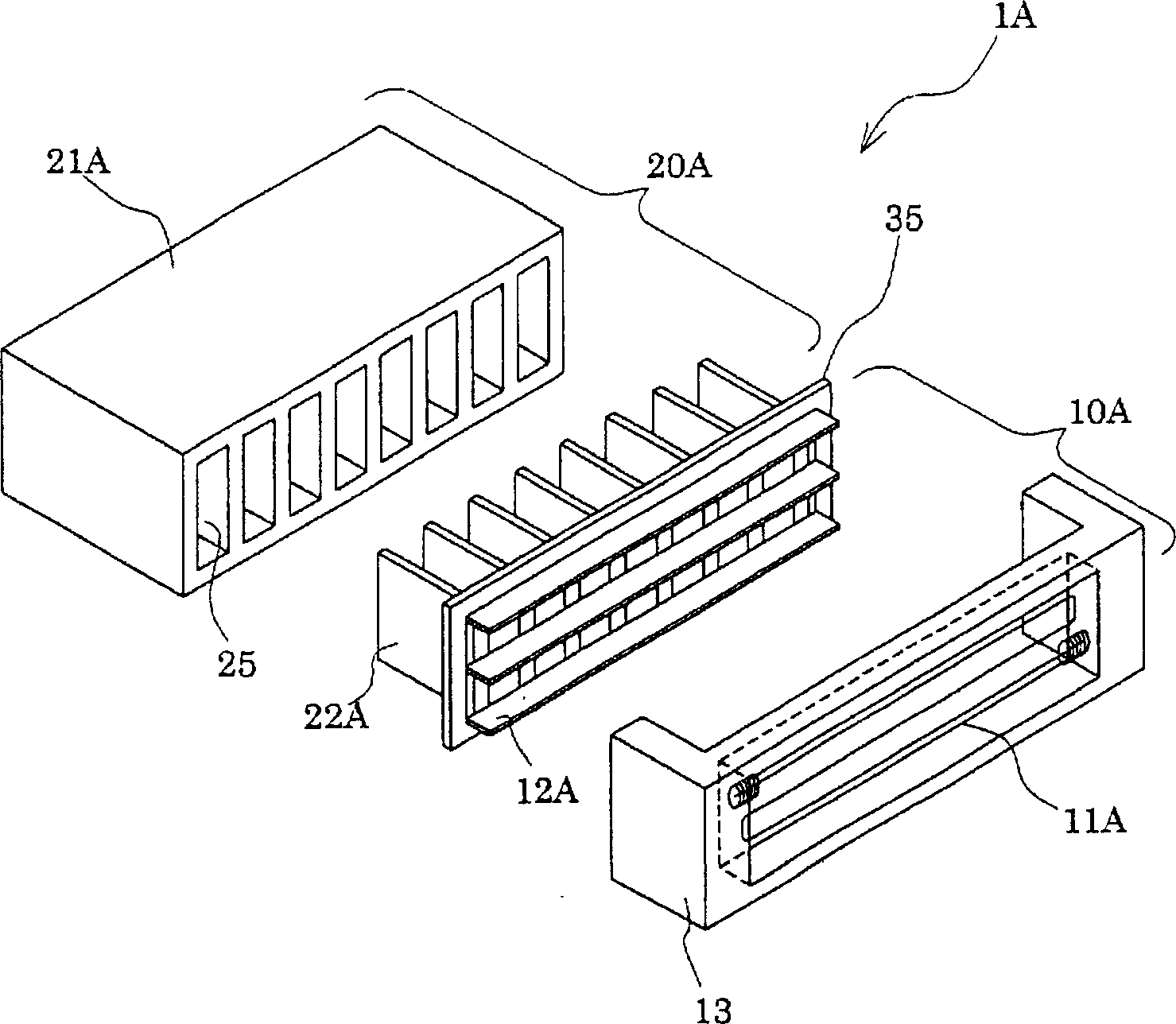

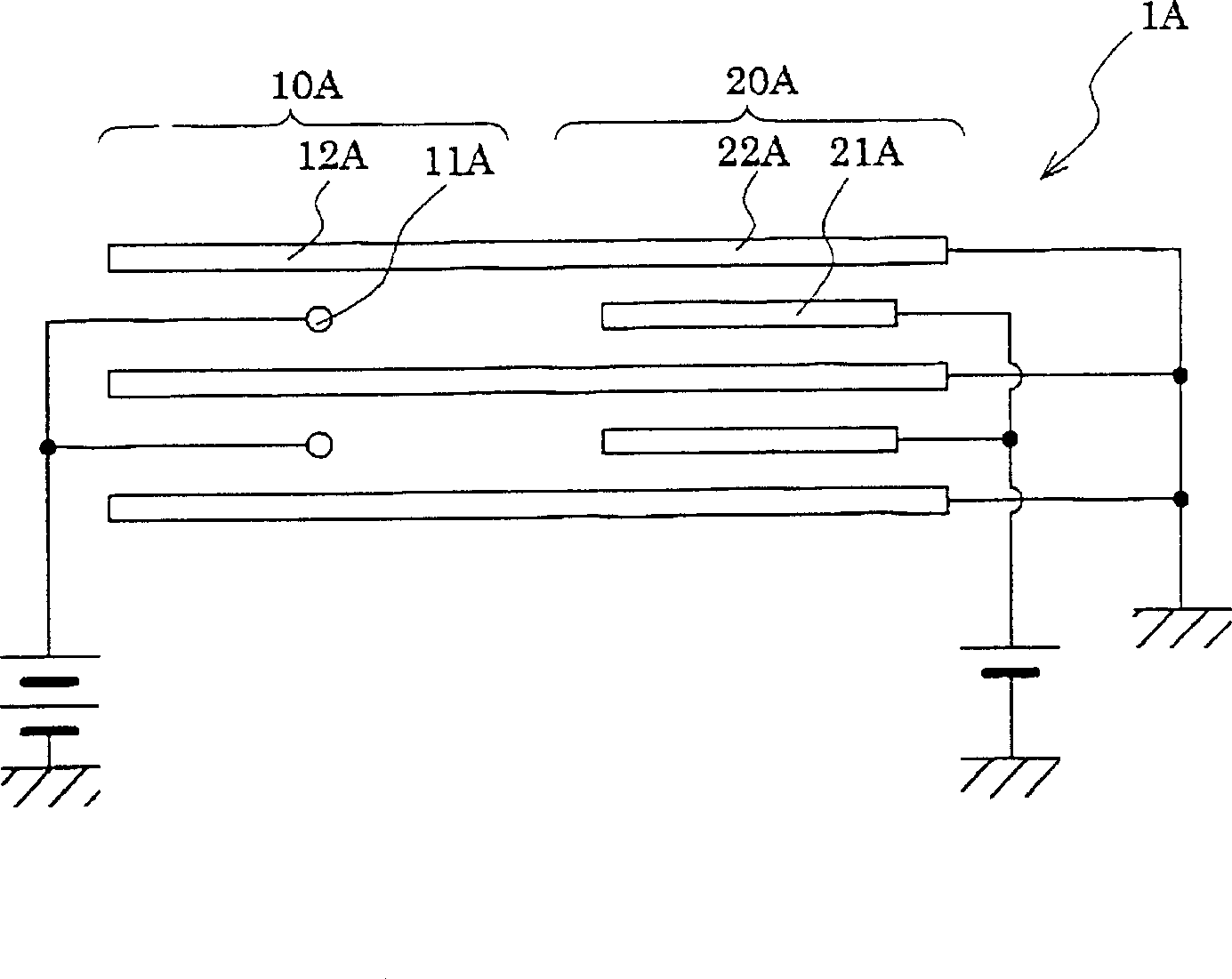

[0061] figure 2 It is an exploded perspective view showing an example of an electrostatic dust collector using a resin electrode according to Embodiment 2 of the present invention. image 3 is its schematic diagram.

[0062] Such as figure 2 with image 3 As shown, the electrostatic dust collector 1A has: an ionization source part 10A as an electrification part composed of a discharge electrode 11A and its counter electrode 12A; when the discharge electrode is connected to a positive potential, it is relatively connected to a positive potential The current collecting part 20A is constituted by the non-dust collecting electrode 21A and the dust collecting electrode 22A oppositely connected to the negative potential. In addition, when the discharge electrode 11A is connected to a negative potential, the potential of each electrode may be set in the same manner as in Embodiment 1 described above.

[0063] The counter electrode 12A of the ionization source part 10A and the d...

Embodiment 1

[0069] A resin electrode of 100 mm x 26 mm x 0.8 mm (thickness) was molded using a conductive resin made of ketchen black (CB) in which 30% by weight of conductive carbon black was blended into a polypropylene resin. The volume resistivity is 10 0 ~10 1 Ωcm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com