Complete solid state nanocrystalline solar battery and its preparing method

A solar cell and nanocrystalline technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of low production cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

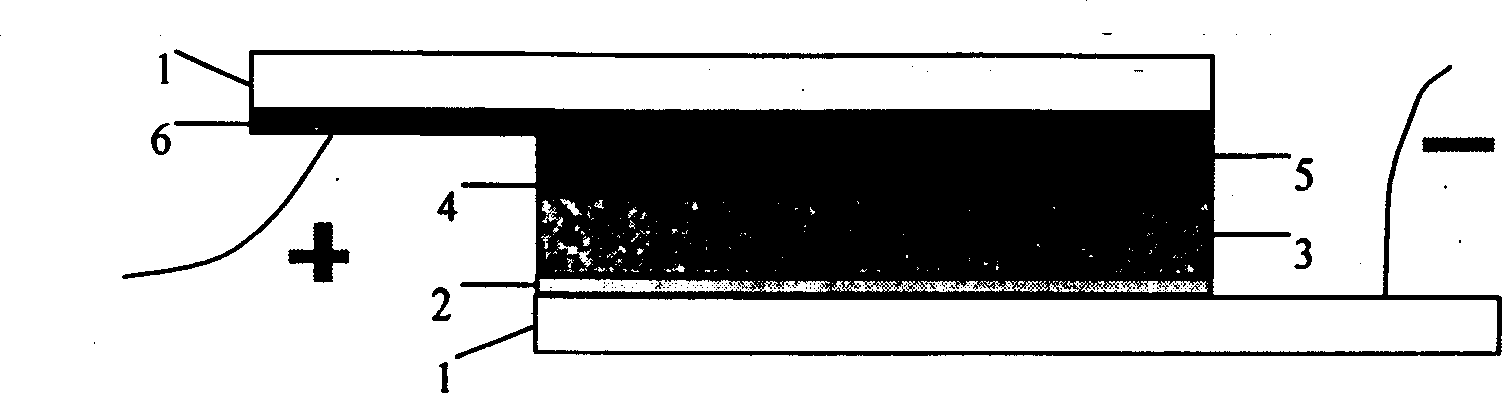

Method used

Image

Examples

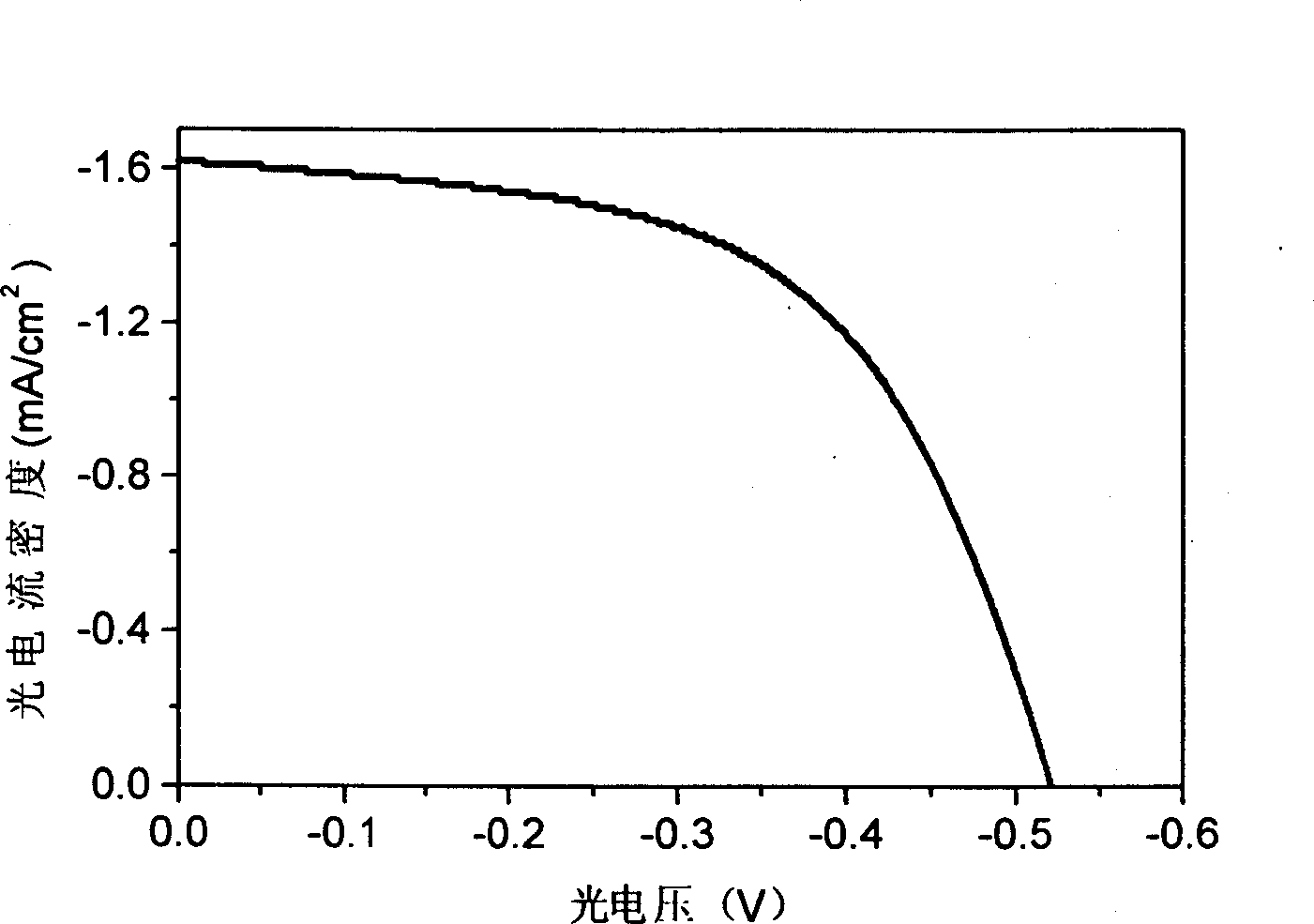

Embodiment 1

[0033] Clean the conductive glass and prepare TiO by spin coating method 2 Dense layer. Then TiO 2 The sol is uniformly coated on the electrode and sintered at 450℃ to form TiO 2 Nanocrystalline electrode, the film thickness is 1-10μm. The electrode was immersed in the ethanol solution of the ruthenium complex and left for 2 days. After taking it out, it was repeatedly rinsed with ethanol and dried. Polyaniline with a conductivity of 300S / cm was applied to the dye-sensitized electrode in a drop film manner as a solid electrolyte. Finally, platinum-plated conductive glass is used as the counter electrode to form a solar cell. The open-circuit photovoltage is 173mV, and the short-circuit photocurrent is 0.37mA / cm 2 , The photoelectric conversion efficiency is 0.02%.

Embodiment 2

[0035] Clean the conductive glass and prepare TiO by spin coating method 2 Dense layer. Then TiO 2 The sol is uniformly coated on the electrode and sintered at 450℃ to form TiO 2 Nanocrystalline electrode, the film thickness is 1-10μm. The electrode was immersed in the ethanol solution of the ruthenium complex and left for 2 days. After taking it out, it was repeatedly rinsed with ethanol and dried. Polyaniline with a conductivity of 100S / cm was applied to the dye-sensitized electrode in a drop film manner as a solid electrolyte. Finally, platinum-plated conductive glass is used as the counter electrode to form a solar cell. Its open circuit photovoltage is 319mV, short circuit photocurrent is 0.51mA / cm 2 , The photoelectric conversion efficiency is 0.08%.

Embodiment 3

[0037] Clean the conductive glass and prepare TiO by spin coating method 2 Dense layer. Then TiO 2 The sol is uniformly coated on the electrode and sintered at 450℃ to form TiO 2 Nanocrystalline electrode, the film thickness is 1-10μm. The electrode was immersed in the ethanol solution of the ruthenium complex and left for 2 days. After taking it out, it was repeatedly rinsed with ethanol and dried. Polyaniline with a conductivity of 10S / cm was applied to the dye-sensitized electrode in a drop film manner, as a solid electrolyte. Finally, platinum-plated conductive glass is used as the counter electrode to form a solar cell. The open-circuit photovoltage is 332mV, and the short-circuit photocurrent is 0.72mA / cm 2 , The photoelectric conversion efficiency is 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com