Carbon micromillimeter tube loading cerium dioxide micromillimete particles and method for making the same

A technology of carbon nanotubes and ceria, applied in chemical instruments and methods, catalyst activation/preparation, catalyst supports, etc., can solve the problems of catalyst performance and utilization rate, particle size and dispersion degree not meeting the ideal requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

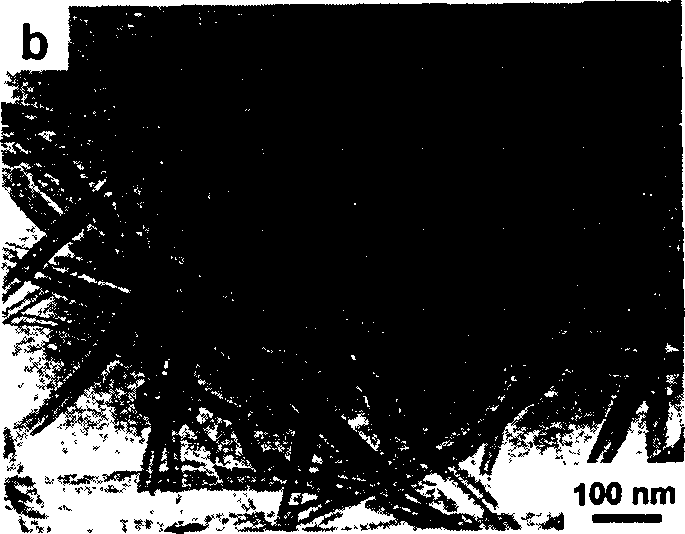

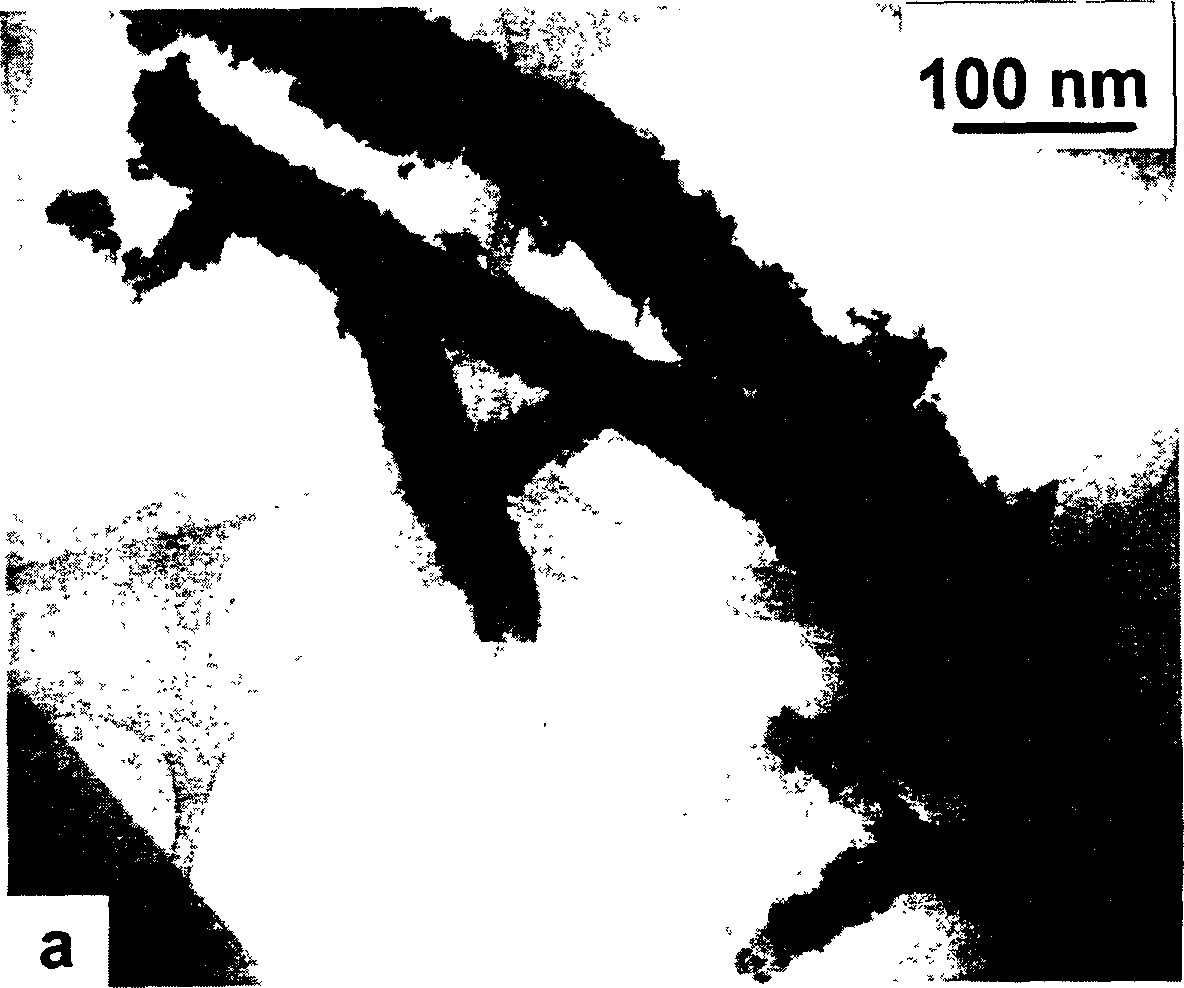

[0028] (1) In a mixed solvent of ethanol and distilled water (v / v is 1:1), add carbon nanotubes, stir and sonicate for 20 minutes each;

[0029] (2) Add 0.01g / ml of CeCl to the mixed solution after stirring 3 Solution (the mass ratio of Ce / C is 0.2:1);

[0030] (3) After stirring for a while, slowly drop 0.002g / ml KOH solution until the pH value of the mixed solution is about 11;

[0031] (4) After stirring for 6 hours, obtain solid powder after filtering and drying;

[0032] (5) Heat the solid powder in air at 400°C for 5 minutes.

Embodiment 2

[0034] (1) In a mixed solvent of methanol and distilled water (v / v is 1:1), add carbon nanotubes, stir and sonicate for 20 minutes each;

[0035] (2) Add 0.05g / ml of CeCl to the mixed solution after stirring 3 Solution (Ce / C mass ratio is 1:1);

[0036] (3) After stirring for a while, slowly drop 0.01g / ml ammonia solution until the pH value of the mixed solution is about 11;

[0037] (4) After stirring for 6 hours, obtain solid powder after filtering and drying;

[0038] (5) Heat the solid powder in air at 200°C for 10 minutes.

Embodiment 3

[0040] (1) In a mixed solvent of ethanol and deionized water (v / v is 1:1), add carbon nanotubes, stir and sonicate for 20 minutes each;

[0041] (2) Add 0.1g / ml of CeCl to the mixed solution after stirring 3 Solution (the mass ratio of Ce / C is 1.5:1);

[0042] (3) After stirring for a while, slowly drop into 0.02g / ml NaOH solution until the pH value of the mixed solution is 12;

[0043] (4) After stirring for 6 hours, obtain solid powder after filtering and drying;

[0044] (5) Heat the solid powder in the air at 100°C for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com