Solid insulator and method for manufacturing solid insulator

A solid insulator, insulator technology, applied in insulators, insulators, organic insulators and other directions, can solve the problems of limited mechanical properties and relative brittleness of materials, sudden failure of mechanical devices, etc., and achieve the effect of cheap maintenance, simple design shape, and great flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

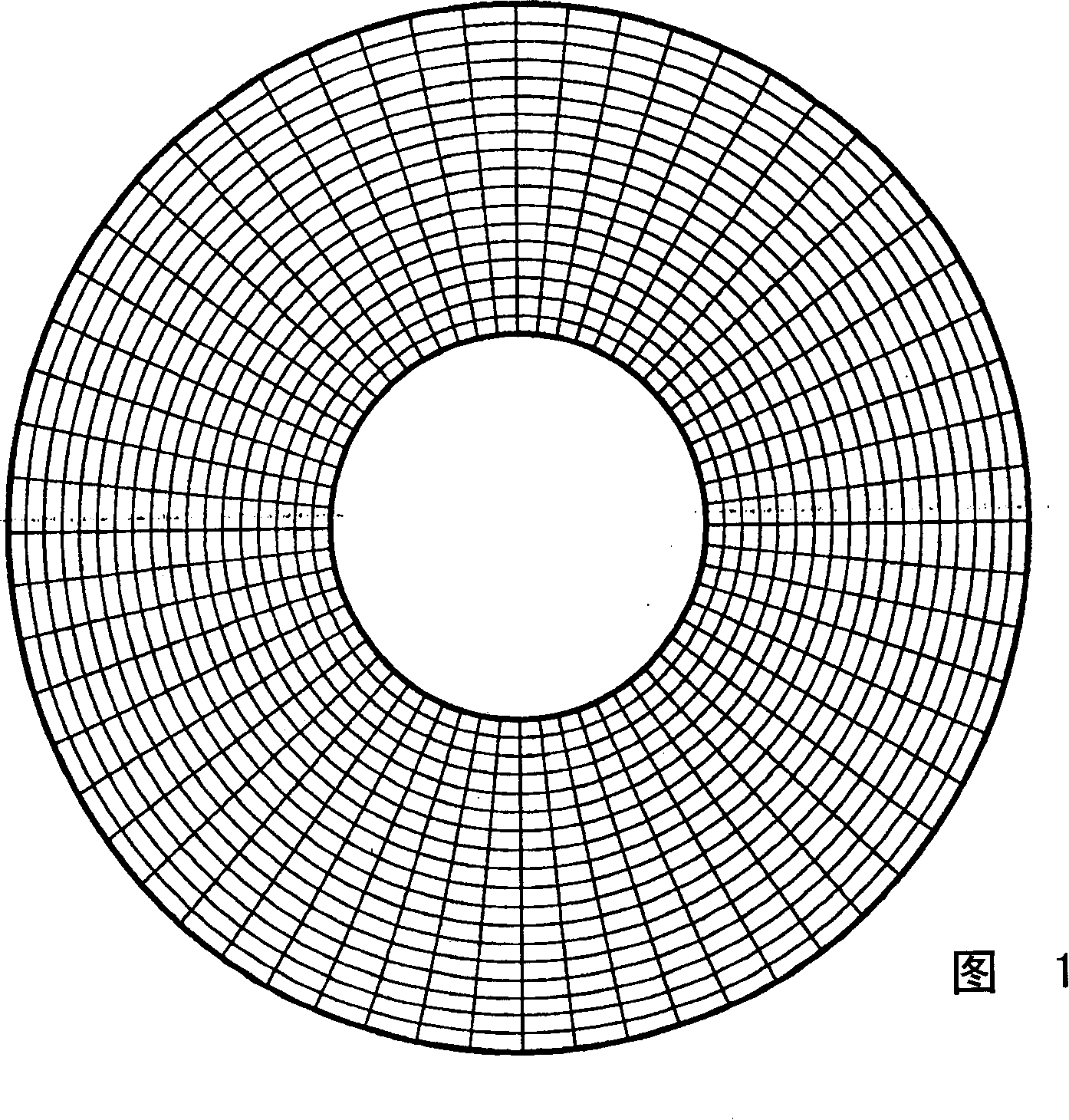

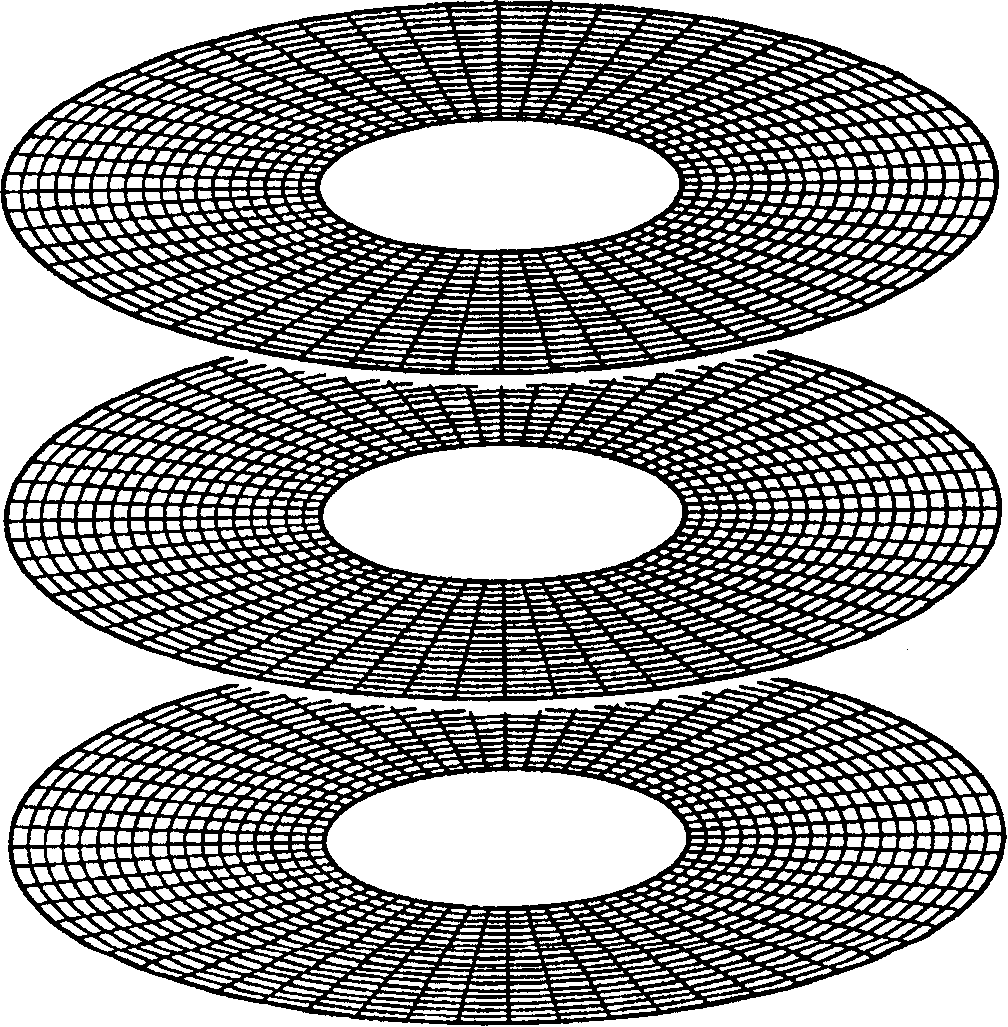

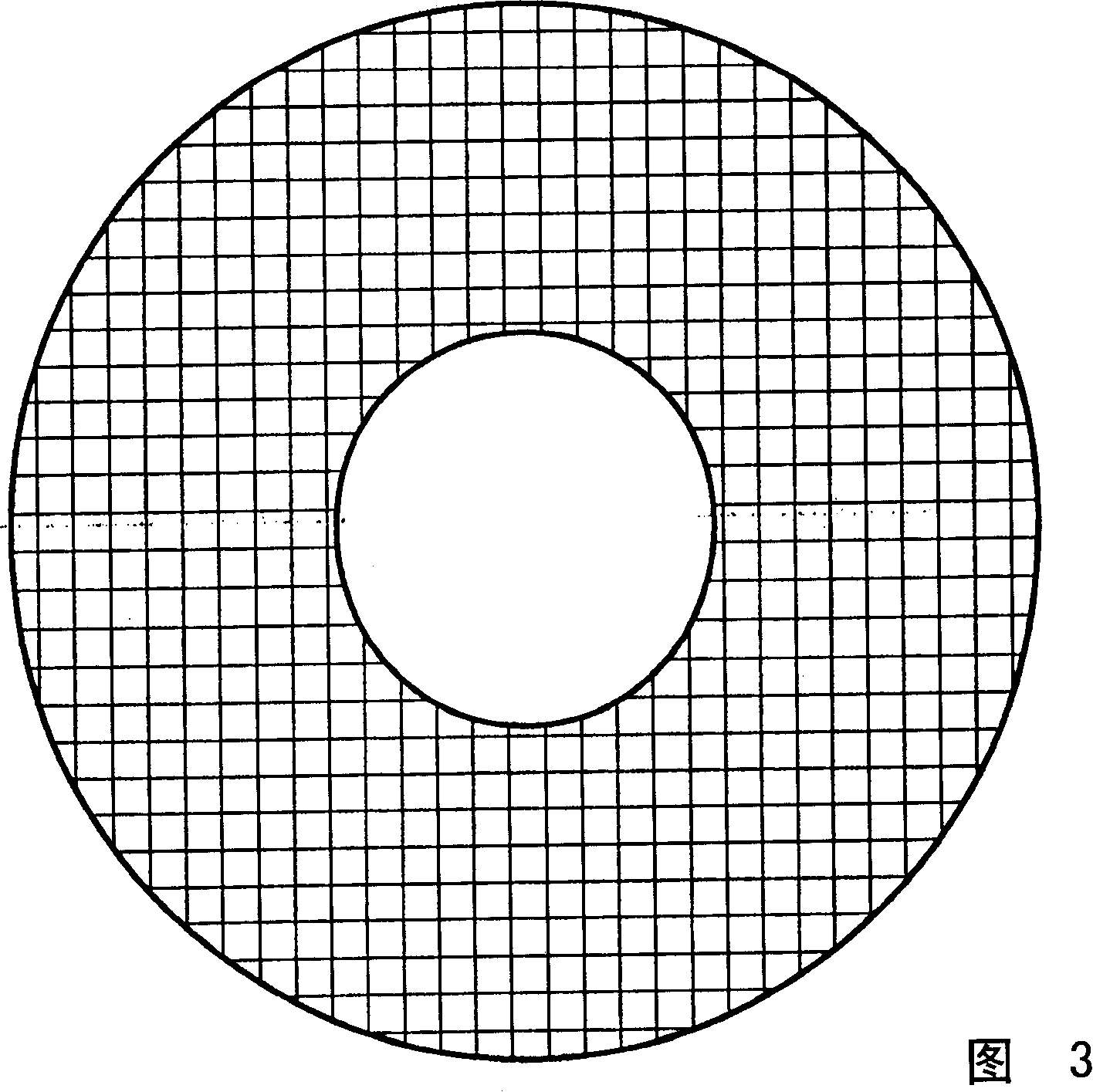

[0026] Fiber-reinforced polymers are a special type of material consisting of a polymer matrix material reinforced with inorganic or organic fibers. The reinforcing fibers are the main load carrier, while the matrix part just transfers the load from fiber to fiber. In this specification, the polymer matrix is composed of a typical anhydride cured epoxy resin usually used in electrical insulators, while the kind of reinforcing fibers can be of different types as long as it includes good electrical insulating properties. In general, glass fibers are of course the most suitable fibers for this solid electrical insulation application, especially E-RC glass fibers. However, other inorganic fibers such as basalt and quartz fibers, and organic fibers such as liquid crystal polymer, aromatic polyamide and polyethylene (p-phenylene-2,6-benzobisoxazole) fibers may also be used. In addition, the polymer matrix can be reinforced in different ways. Fibers can be continuous, in the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com