High activity antidraught nutrient and its making method

A nutrient and highly active technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of affecting the drought resistance effect, unbalanced nutrient composition, poor persistence and controllability in drought resistance and supply of nutrients, etc., to prevent the invasion of pathogens. The effect of dyeing, relieving drought and increasing yield is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

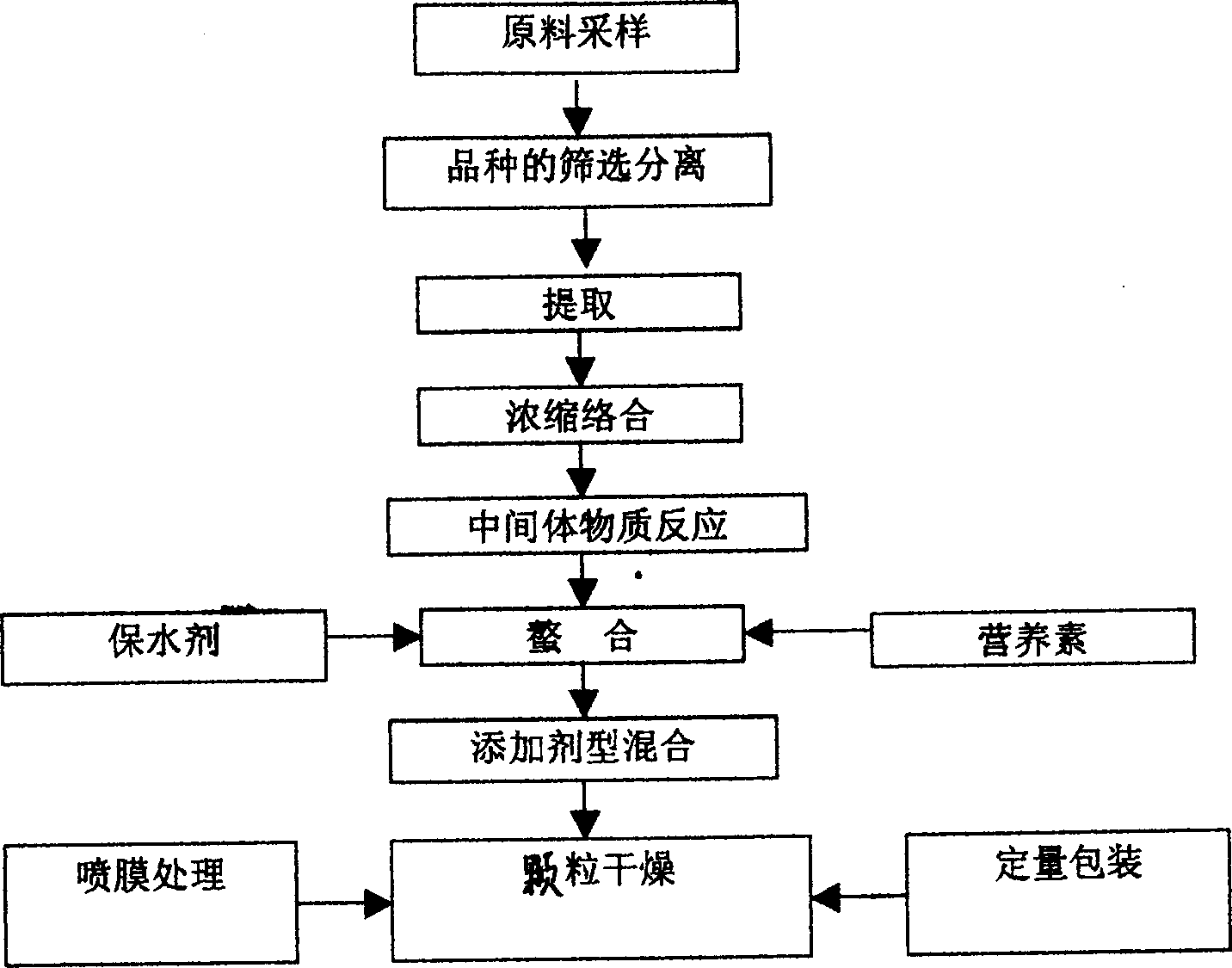

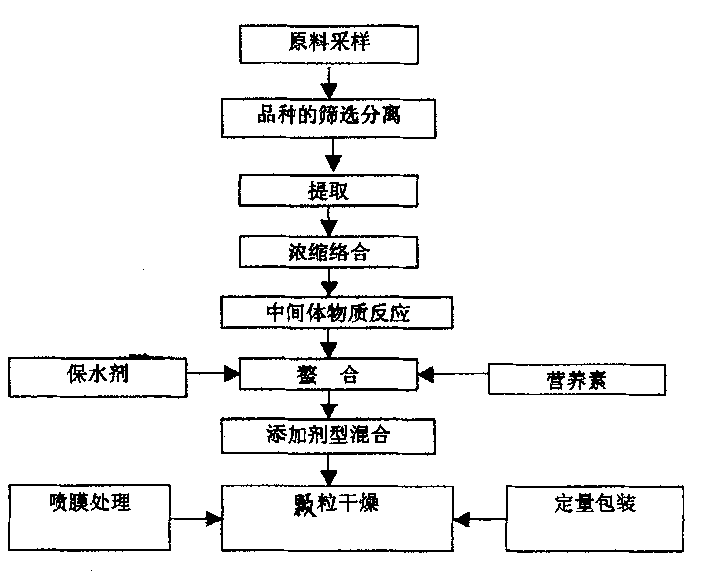

Method used

Image

Examples

Embodiment 1

[0027] Solid product formula: ammonium humate (HA35%) 500kg, coated urea (N46%) 150kg, calcium magnesium phosphate fertilizer (P14) 100kg, ammonium phosphate (N17, P44) 100kg, chitin (degreasing treatment) 20kg, matrine (80 mesh) 20kg, bentonite (including colloid price > 50ml / 5g) 30kg, process water 380kg, organic matter (55%) 50kg, bone meal (120 mesh) 40kg, rare earth (99.9%) 1.2kg, medical stone 30kg.

[0028] Process steps:

[0029] First make ammonium humate as required, then add coated urea, calcium magnesium phosphate fertilizer, and ammonium phosphate, add chitin, matrine, organic matter, bone meal, rare earth, medical stone, and finally add bentonite to form granules Finally, it automatically rolls out of the granulator, and enters the dryer for drying, air-drying and packaging. Wherein the reaction temperature is 80° C., and the reaction time is 8 hours.

Embodiment 2

[0031] Solid product formula: fulvic acid (HA35%) 25kg, amino acid (MAA12%) 5kg, matrine 9kg, alkaloid 5kg, chitosan 7.25kg, process water 1000kg, organic nitrogen (N46%) 8.5kg, calcium ( Ca99%) 1.5kg, boron (B99%) 1.5kg, manganese (Mn98.9%) 1.75kg, zinc (Zn98.9%) 0.15kg, organic matter 6kg, rare earth (99%) 0.15kg.

[0032] Process steps:

[0033] The above raw materials are processed and divided into three groups of reactants:

[0034] The first group: neutralize fulvic acid and amino acids and place them in a reactor;

[0035] The second group: stirring matrine, alkaloids and chitosan continuously during the full reaction process;

[0036] The third group: mixing and reacting organic nitrogen, calcium, boron, manganese, zinc, organic matter and rare earth.

[0037] The reaction time is 8 hours. After the reaction, mix the first group of reactants with the third group of reactants and keep stirring to prevent precipitation, and then slowly add the third group of reactants...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com