Metal oxide catalyst for preparing bundle-formed multiwall nano carbon tube, its preparation method and application

A technology of multi-walled carbon nanotubes and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low utilization and catalytic efficiency, nano The quality of carbon tubes is not high, the primary product has many impurities, etc., to achieve the effect of strong activity, high utilization rate and good graphitization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add ammonium molybdate to ethylene glycol solution, heat and reflux at 90°C and stir for 4-6 hours until completely dissolved. Ferric nitrate nonahydrate and magnesium nitrate hexahydrate are respectively dissolved in hexanediol and slightly heated to form alkoxide. The molar ratio of iron:molybdenum:magnesium is 0.1:1:1. Keep it warm at 700°C for 30 minutes, take it out and cool it, and grind it finely to obtain a catalyst for preparing bundled multi-walled carbon nanotubes.

Embodiment 2

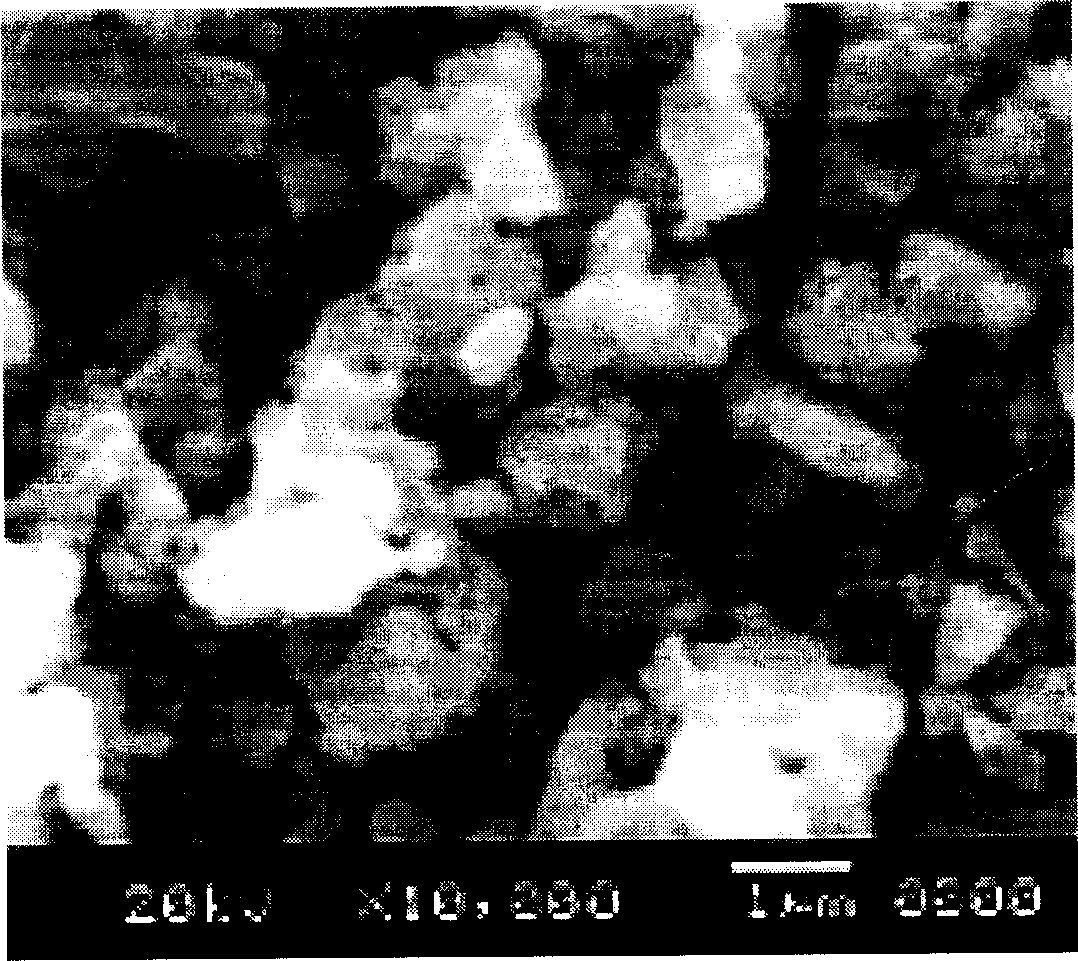

[0017] Add ammonium molybdate to ethylene glycol solution, heat and reflux at 90°C and stir for 4-6 hours until completely dissolved. Ferric nitrate nonahydrate and magnesium nitrate hexahydrate are respectively dissolved in hexanediol and slightly heated to form alkoxide, and the molar ratio of iron:molybdenum:magnesium is 0.1:1:1 and mixed. Transfer to a porcelain boat, burn at 700°C in a muffle furnace, then keep warm at this temperature for 10 minutes, take out the formed solid and cool it down and grind it finely to obtain a catalyst for preparing bundled multi-walled carbon nanotubes. SEM photographs of the catalyst are shown in figure 1 .

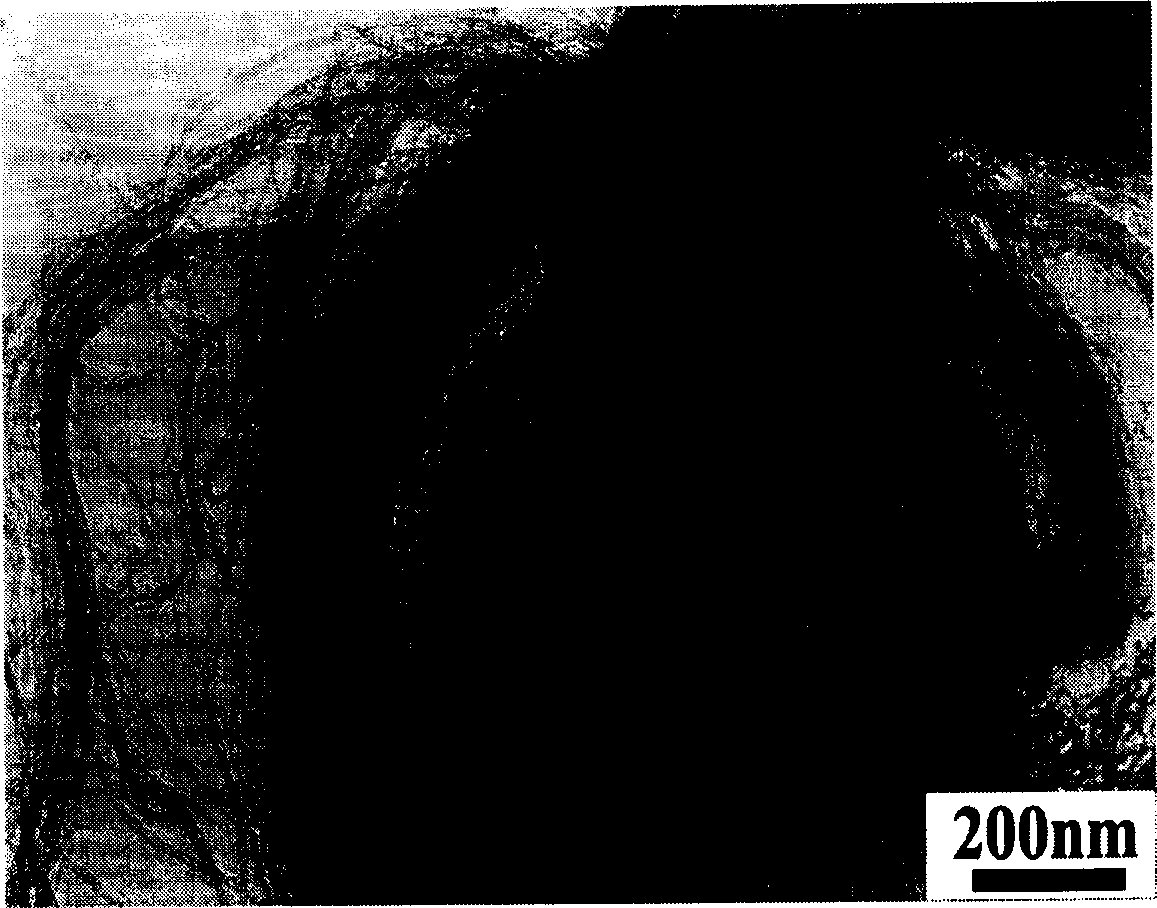

[0018] The carbon tubes were prepared in a fixed-bed gas continuous flow reaction furnace. Put 0.105 grams of catalyst into the constant temperature zone in the middle of the furnace, feed methane with a flow rate of 900 sccm and hydrogen with a flow rate of 50 sccm, control the reaction temperature at 1000°C, and react for 30 minu...

Embodiment 3

[0020] Add ammonium molybdate to ethylene glycol solution, heat and reflux at 90°C and stir for 4-6 hours until completely dissolved. Cobalt nitrate hexahydrate and magnesium nitrate hexahydrate are respectively dissolved in hexanediol and slightly heated to form alkoxide, and the molar ratio of cobalt:molybdenum:magnesium is 0.1:1:1 and mixed. Transfer to a porcelain boat, burn at 700°C in a muffle furnace, keep warm at this temperature for 10 minutes, take out the formed solid and cool it down and grind it finely to obtain a catalyst for preparing bundled multi-walled carbon nanotubes. Figure 4 is the XRD pattern of the catalyst.

[0021] The carbon tubes were prepared in a fixed-bed gas continuous flow reaction furnace. Put 0.145 grams of catalyst into the constant temperature zone in the middle of the furnace, feed methane with a flow rate of 900 sccm and hydrogen with a flow rate of 50 sccm, control the reaction temperature at 1000°C, and react for 30 minutes to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com