Cross mark transport method, cross mark transport device and exposure device

A technology for cross mark and handling device, which is applied in the direction of exposure device, printing device, transportation and packaging of photoplate making process, and can solve the problems of unable to maintain the cross mark substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

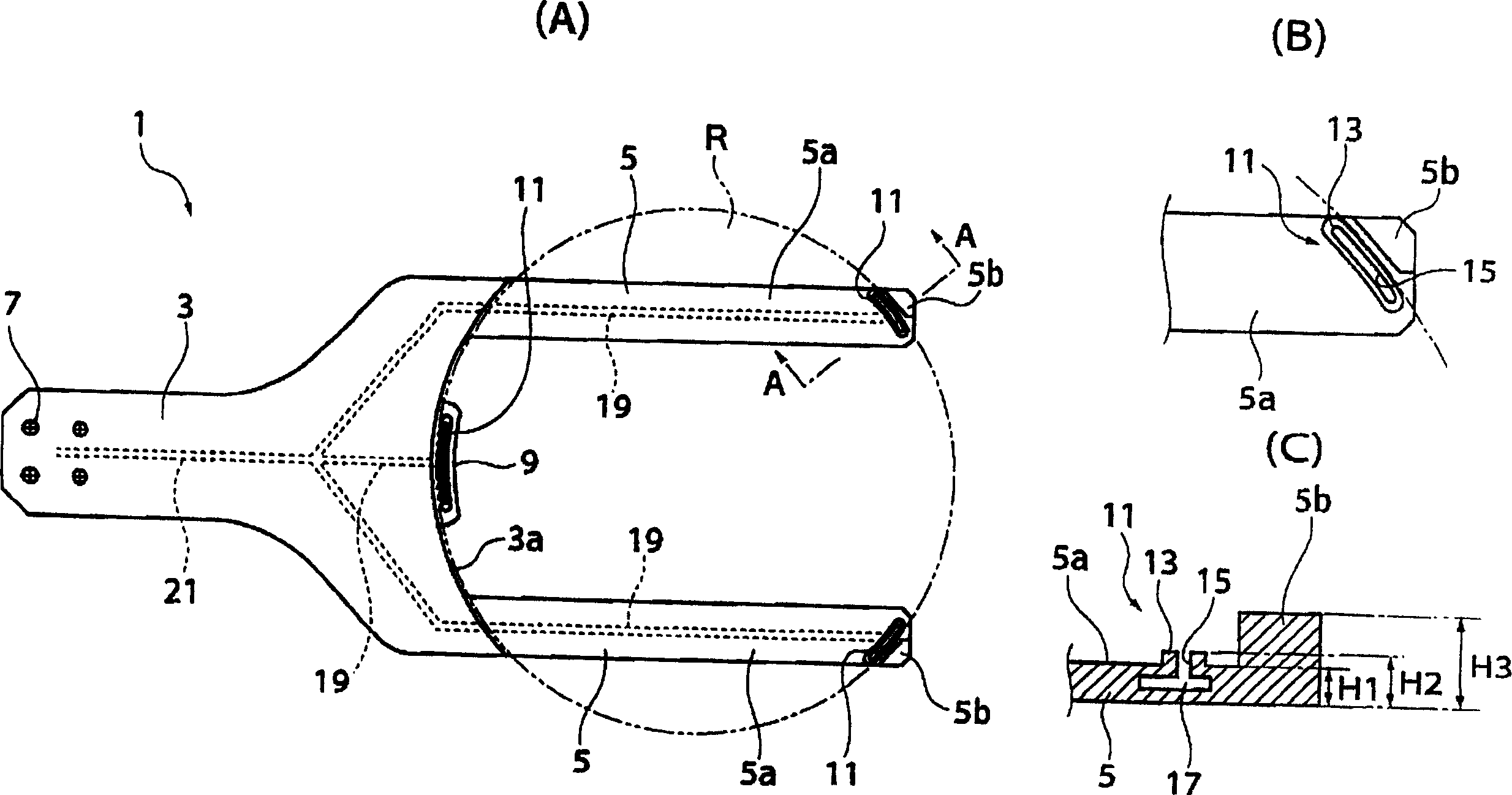

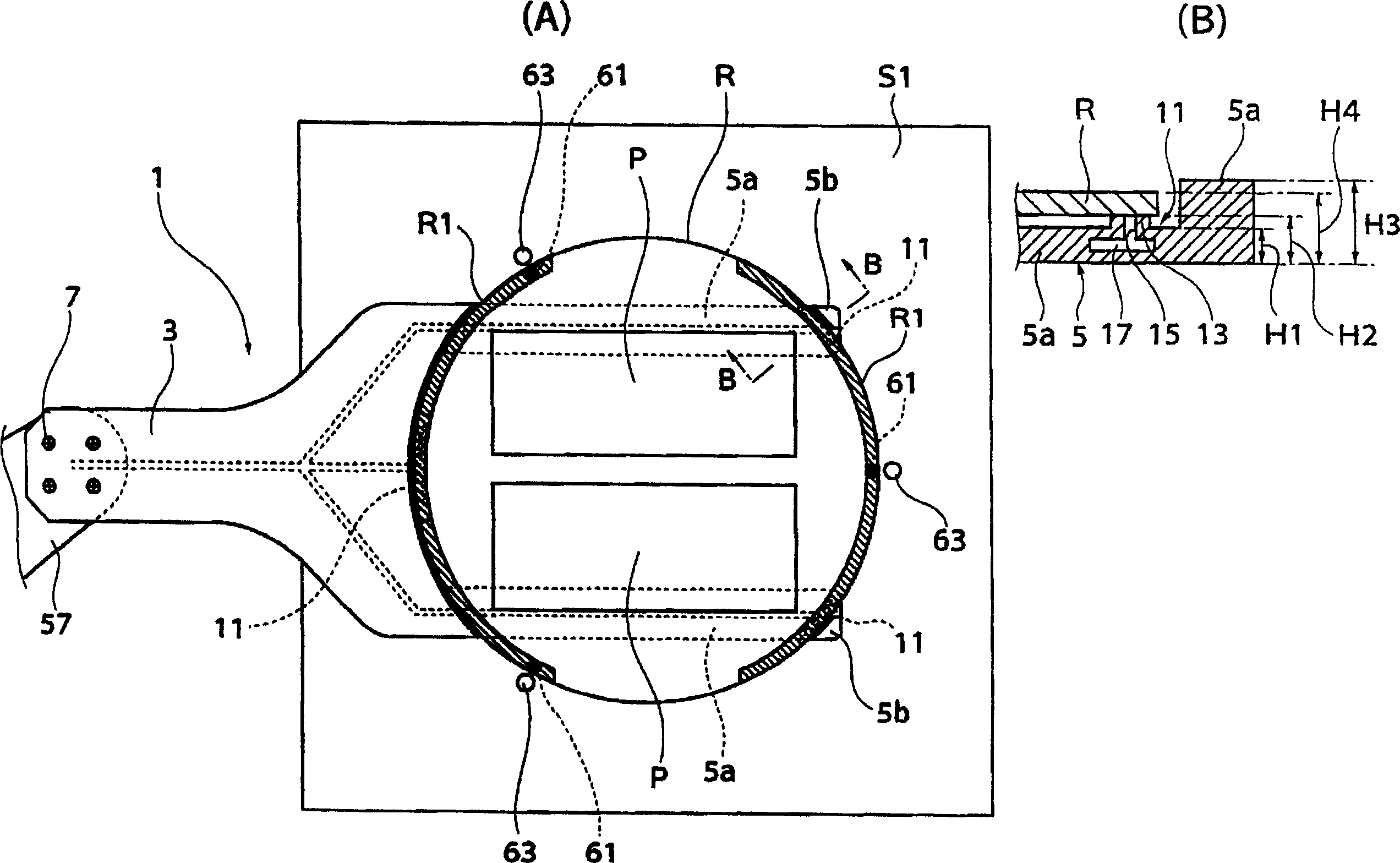

[0069] Next, the embodiments of the present invention will be described with reference to the drawings.

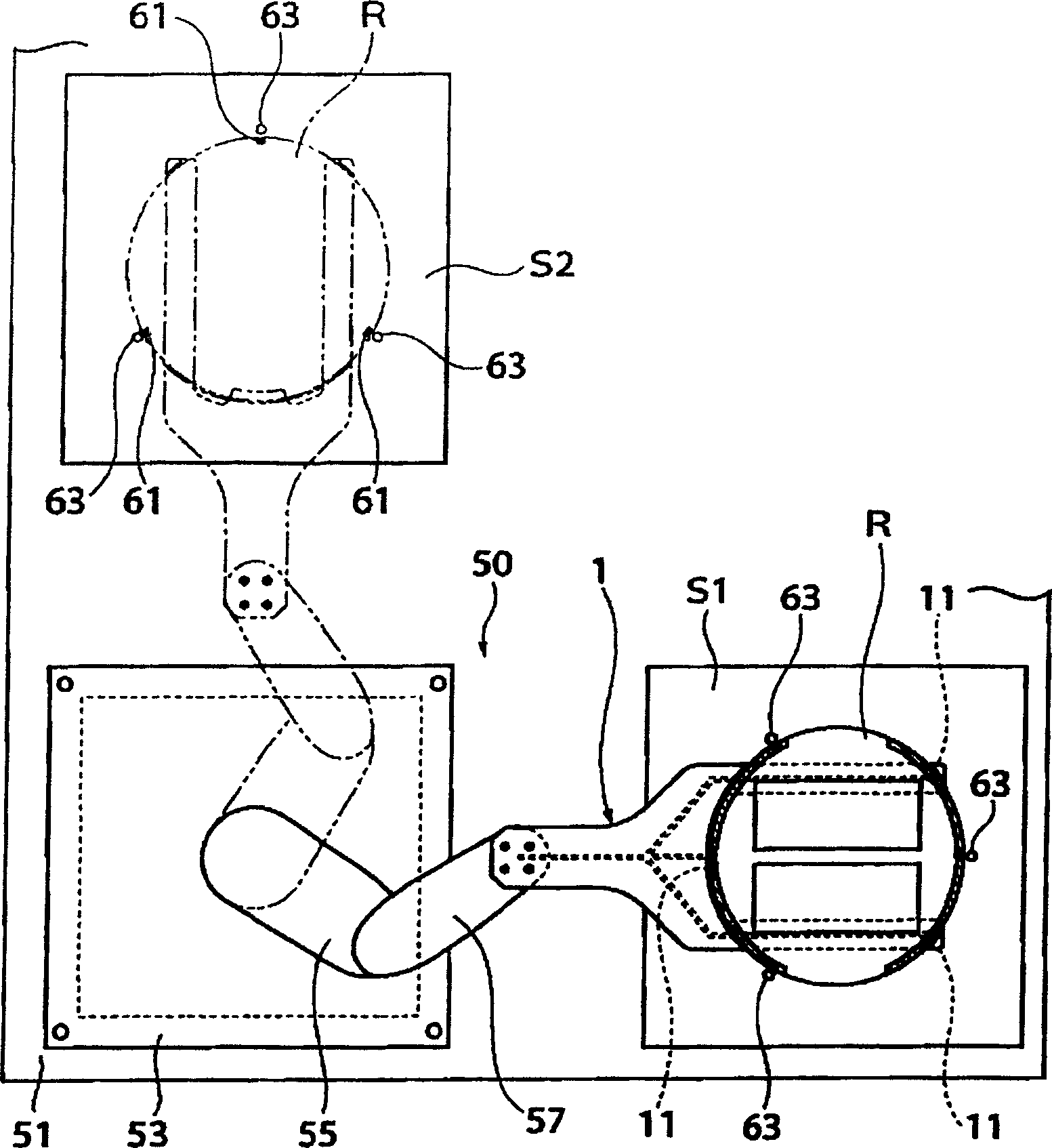

[0070] figure 2 It is a plan view of the overall structure of the cross mark conveying device according to the embodiment of the present invention.

[0071] Figure 3A is a diagram showing figure 2 An enlarged view of part of the cross marking handling device. FIG. 3B is a cross-sectional view along line B-B of FIG. 3A.

[0072] first reference figure 2 The overall structure of the cross mark transfer device will be described.

[0073] The cross conveyance device 50 conveys the cross R between two workstations (stations) S1 and S2 in the atmosphere. The workstation can be, for example, a reticle pot, a pre-aligner chamber, or a load-lock chamber, among others. This mechanical arm (cross mark carrying device) 50 comprises the base 53 that is fixed on the stand 51; The first arm 55 that is rotatably installed on the base 53; the second arm 57 ; and a U-shaped hook (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com