Oil-containing sewage floatation cyclone coupling separation method

A separation method and technology of oily sewage, applied in the direction of separation method, liquid separation, flotation water/sewage treatment, etc., can solve the problem of ineffective separation of tiny oil droplets and sewage separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

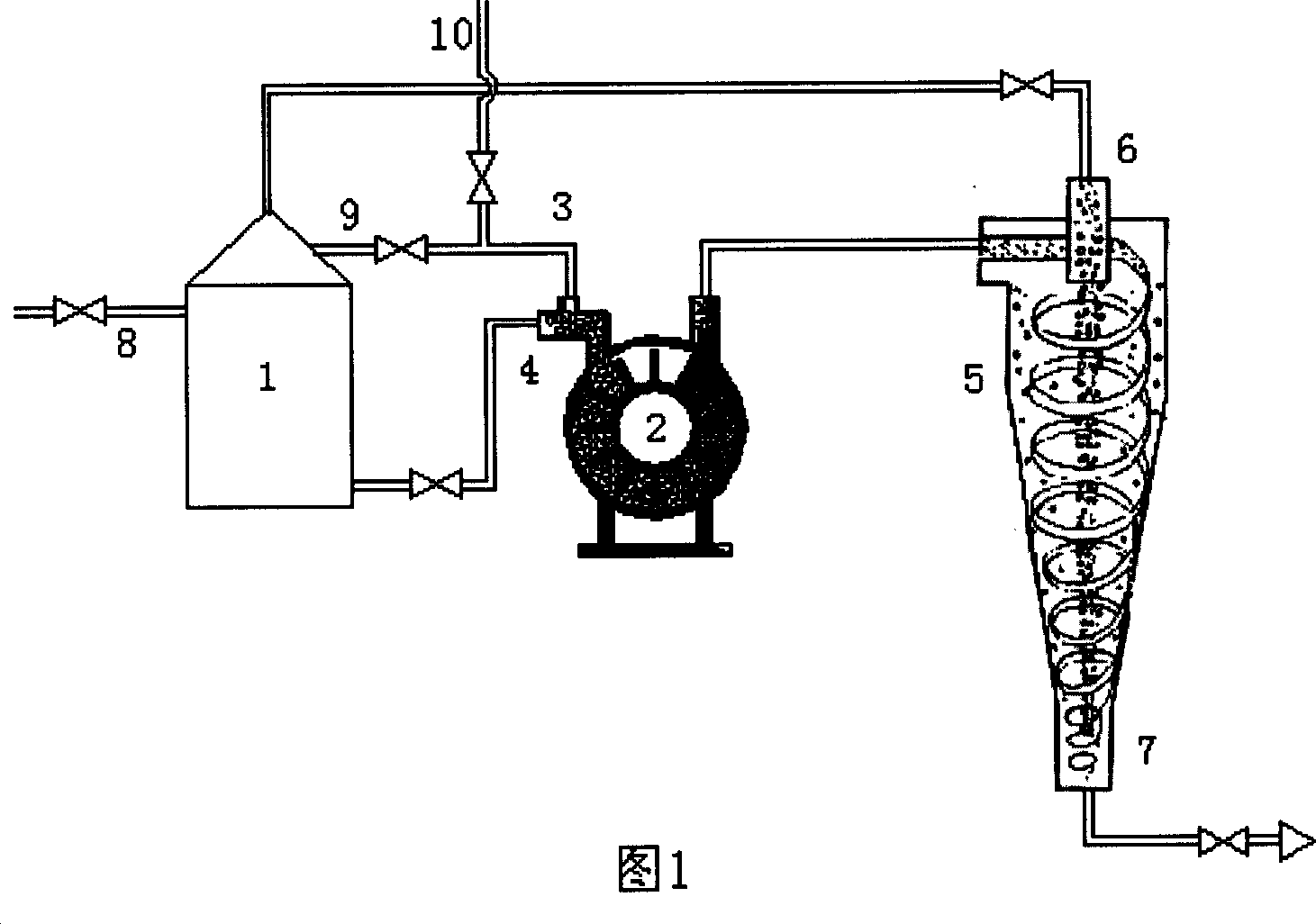

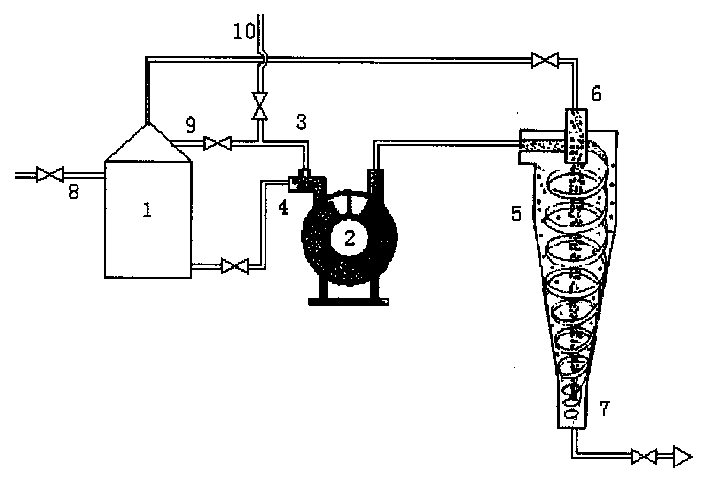

[0028] In the oil-water separation device shown in Figure 1, the oily sewage from the oily sewage tank (1) is sucked, stirred, pressurized and solubilized by the vortex pump (2), and then enters the deoiling cyclone (5). Said sewage has an oil concentration of 583.6mg / L and an air intake of 0.5m 3 / h, the inlet pressure is 0.4MPa, and the bottom outlet pressure of the deoiling cyclone is 0.2MPa. After the operation is stable, the separation efficiency of the oil-water separation method of the deoiling cyclone of the present invention is calculated through sampling analysis at the bottom outlet. was 86.2%.

Embodiment 2

[0030] In the separation device shown in Figure 1, except that the suction volume is 1m 3 / h and the oil concentration in the sewage are except 549.8mg / L, all the other conditions are all with embodiment 1. The separation efficiency of the oil-water separation method of the deoiling cyclone of the present invention is calculated to be 88.4% through sampling analysis and determination.

Embodiment 3

[0032] In the separation device shown in Figure 1, except that the suction volume is 2m 3 / h and the oily concentration in sewage are except 564.5mg / L, all the other conditions are all with embodiment 1. The separation efficiency of the oil-water separation method of the deoiling cyclone of the present invention is calculated to be 90.3% through sampling analysis and measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com