Flexible wiring boards for double-side connection

A wiring board, double-sided technology, applied in the field of flexible wiring boards for double-sided connection, can solve the problems of loss of smoothness, contamination, and reduced reliability of circuit substrates, and achieve the effect of high-efficiency manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the flexible wiring board for double-sided connection of the present invention will be described in detail with reference to the drawings.

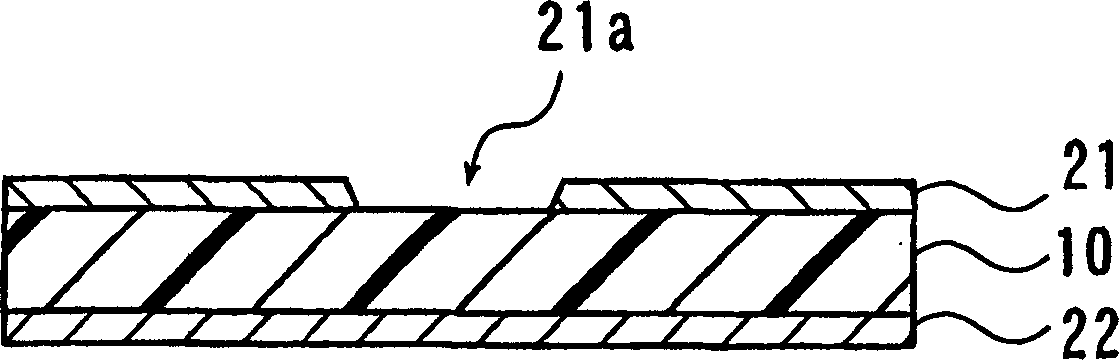

[0030] Figure 1a ~ Figure 1e It is a process drawing which shows the manufacturing method of the flexible wiring board for double-sided connection of this embodiment.

[0031] Such as Figure 1a As shown, first, a laminated body 1 is prepared, and the laminated body is provided with first and second copper foils (metal foils) 21 and 22 on both surfaces of, for example, a polyimide film (insulating base material) 10 .

[0032] Next, if Figure 1b As shown, holes 21 a are formed in predetermined positions of the first copper foil 21 by etching with an etchant such as copper chloride, persulfates, ferric chloride, and copper-amine chromium compounds.

[0033] Such as Figure 1c As shown, the exposed portion of the polyimide film 10 is etched with an etchant such as an alkaline solution such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com