Electric pulse minitype plasma water treatment method and equipment

A plasma and electric pulse technology, applied in the application field of the combination of ion chemistry, can solve the problems of high treatment cost, secondary pollution, low treatment efficiency, etc., and achieve the effect of strong sterilization function and efficient sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

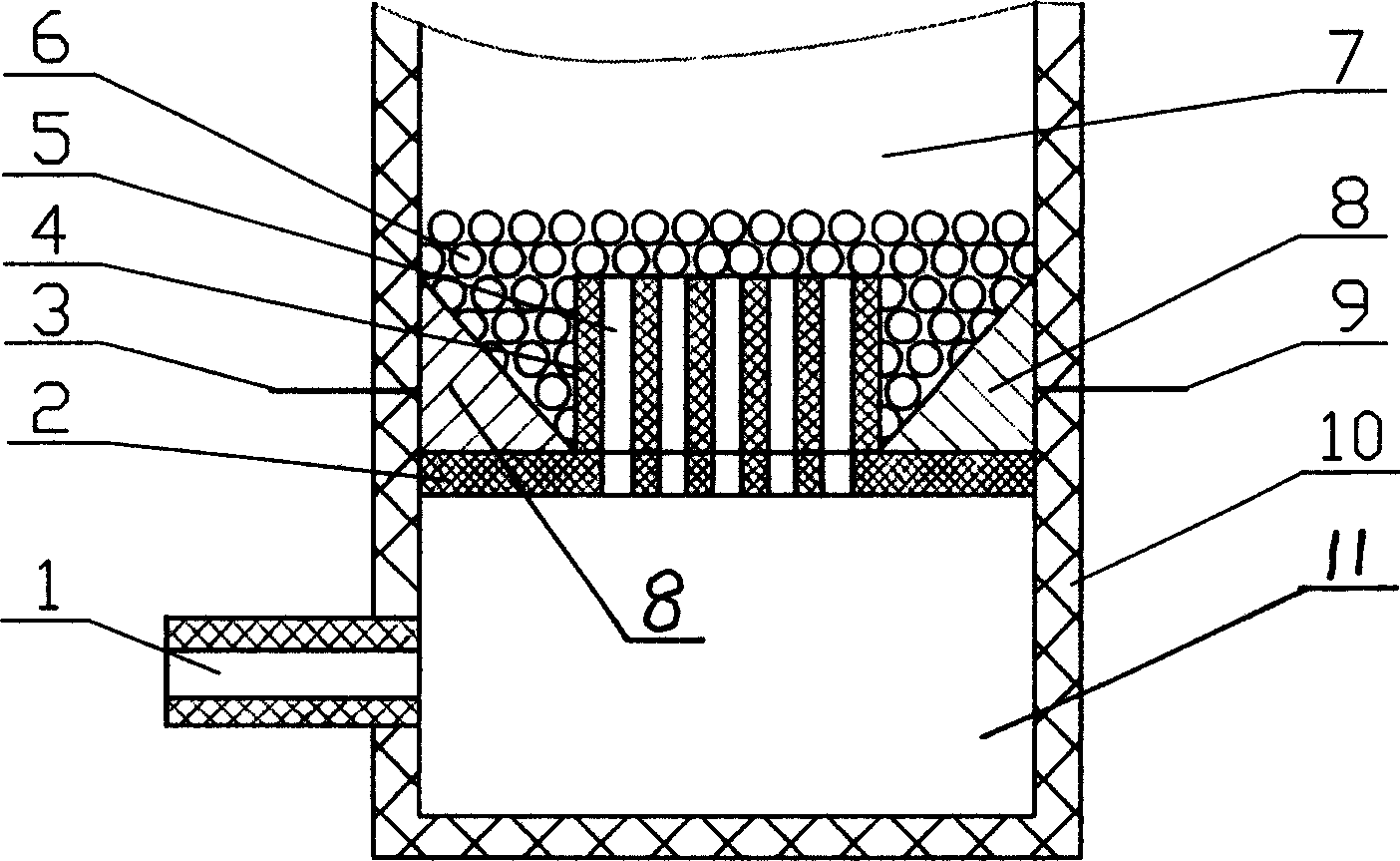

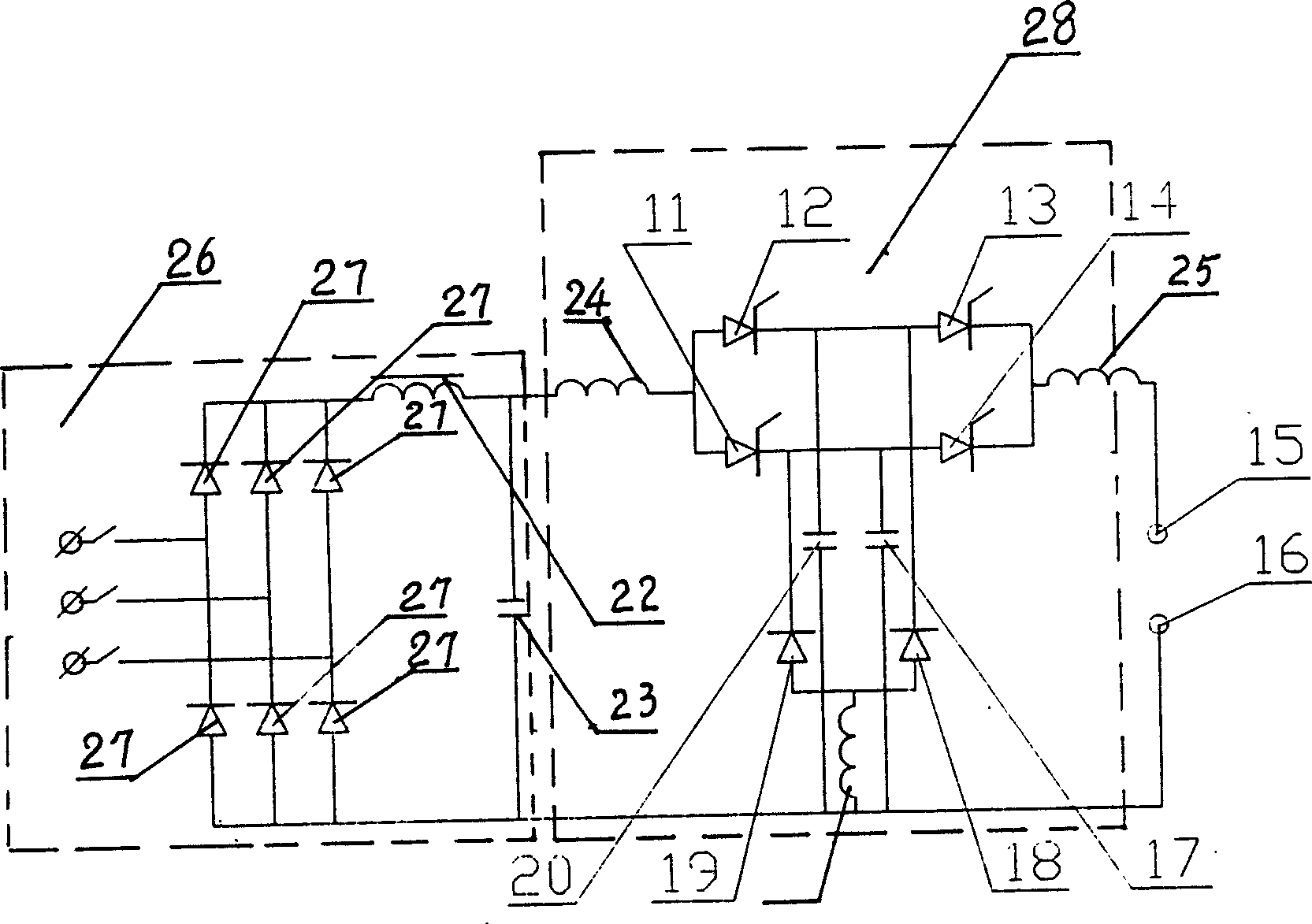

[0038] The discharge reaction chamber (7) of the reactor is filled with metal particles (6), and new metal particles (6) are added to the discharge reaction chamber (7) according to the wear degree of the metal particles (6). The sewage is pumped into the reactor (10) through the water inlet (1), the water inlet chamber (11) and the water inlet channel (5) by the water pump at a flow rate of 2 tons per hour. Impurities contained in sewage (mg / liter): Cr 6+ : 37.8, Cu 2+ : 20.0, Zn 2+ : 19.0, Ni 2+ : 28.5, Sn 2+ , Sn 4+ : 10.0, CN - : 13.5, the total pollutant content of sewage is 128.8 mg / liter, and the pH value of water is 3.8. The applied pulse voltages are 700V and 200V, the corresponding pulse currents are 250A and 800A, the pulse energy is 7J, and the average power is 0.6KW. Sewage is discharged into the sedimentation chamber after being treated by the reactor (10), and a sample is taken for detection after 10 minutes. The residual concentration of impurities in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com