Building section bar ad its assembling method

An assembly method and construction technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of large space occupied by integral parts, long production cycle, difficult installation and connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

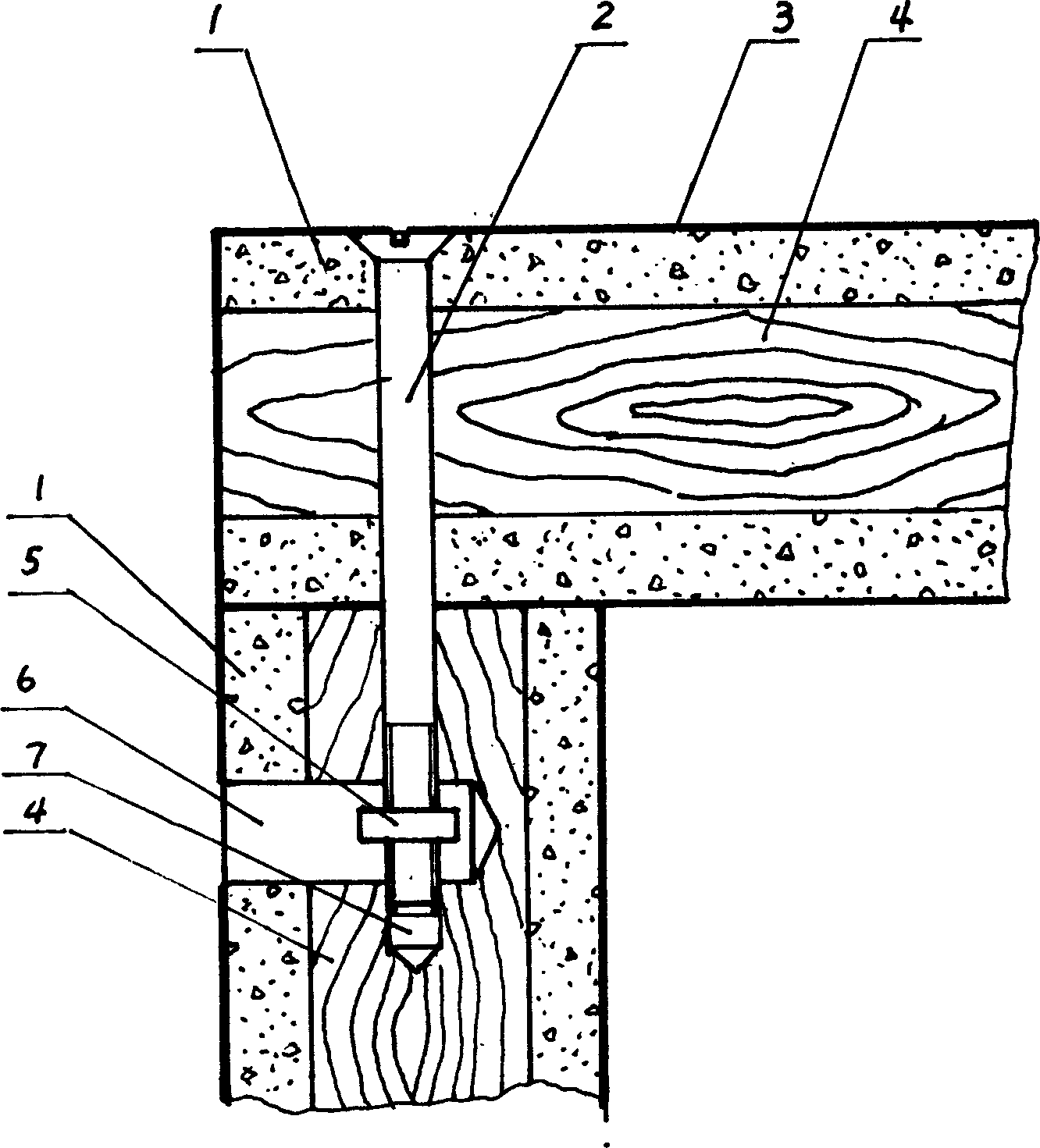

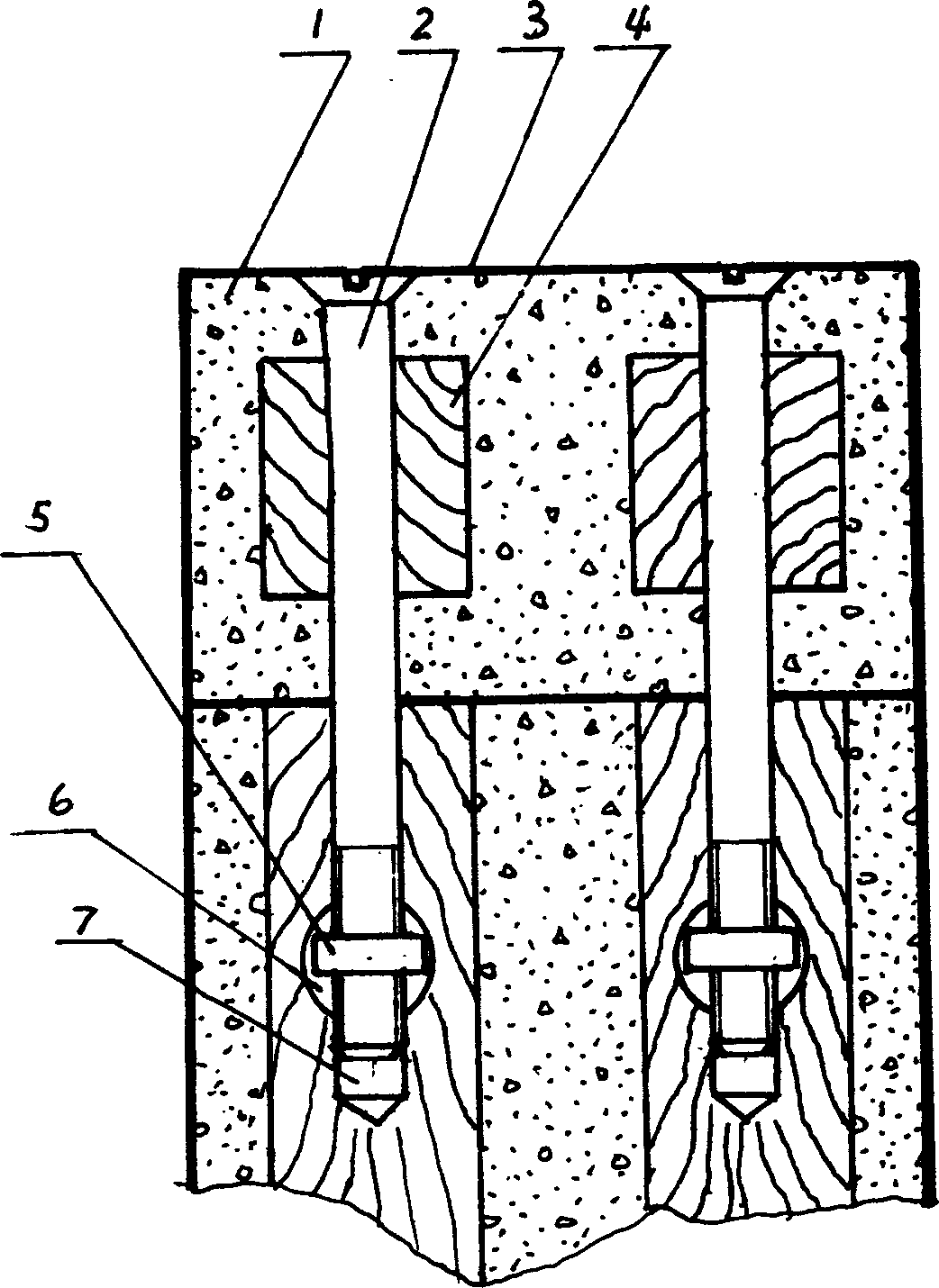

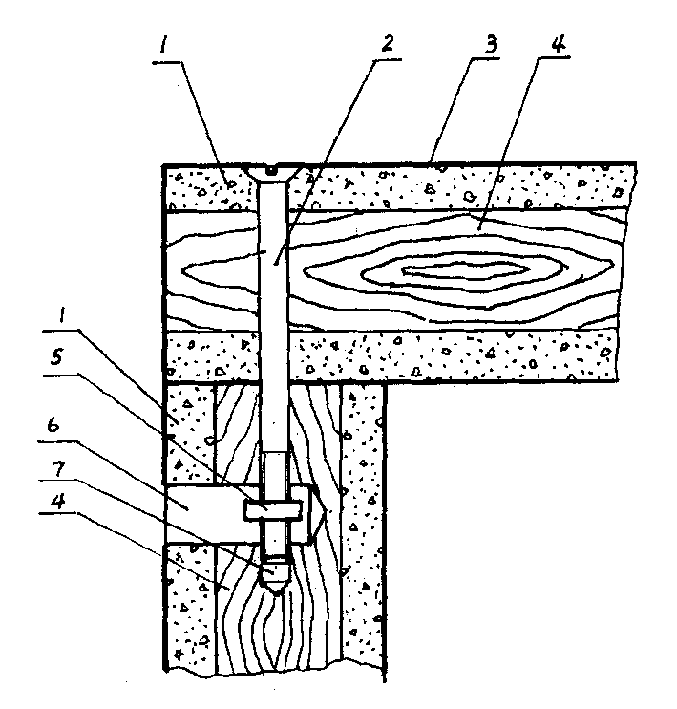

[0010] The present invention will be further described below in conjunction with accompanying drawing and embodiment

[0011] Dissolving brine crystals (mainly composed of magnesium chloride) in water to prepare a 50% aqueous solution of brine crystals. Add 1 part of light-burned magnesite powder (the main component is magnesium oxide) to 1 part (parts by weight, the same below) of brine crystal aqueous solution, and stir evenly; add 0.2 parts of wood sawdust with a particle size of 2mm-5mm, and stir Make slurry 1 evenly. When the slurry 1 is poured into the model, a layer of glass fiber cloth 3 is first laid on the bottom and side walls of the model. During the pouring of the slurry 1, 1-4 wooden core strips 4 are placed longitudinally in the model. After the slurry 1 is filled, Lay a layer of glass fiber cloth 3 on the upper surface of the model, then vibrate and compact the slurry 1, and then solidify to obtain a building profile. Because some of the finer slurry 1 seeps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com