Compact ceramic fiber spraying lining and its working process

A technology of ceramic fiber and construction technology, which is applied in coatings, devices for coating liquid on the surface, lighting and heating equipment, etc., can solve the problems of poor water resistance and thermal shock resistance, and low strength of sprayed linings, and achieve heat resistance High shock resistance, improved anti-flue gas erosion performance, and easy to transform old furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dense ceramic fiber spray lining composed of ceramic fiber and high temperature binder, the high temperature binder contains Al 2 o 3 Micropowder, SiO 2 Micropowder, nanoscale Al 2 o 3 Powder, ammonia and water, wherein the weight percentage of each component is: Al 2 o 3 Micropowder 2.8%, SiO 2 Micropowder 3.5%, nanoscale Al 2 o 3 Powder 1.0%, ammonia water 0.9%, water 91.8%, admixture in proper amount. The sum of the content percentages of each component is 100%.

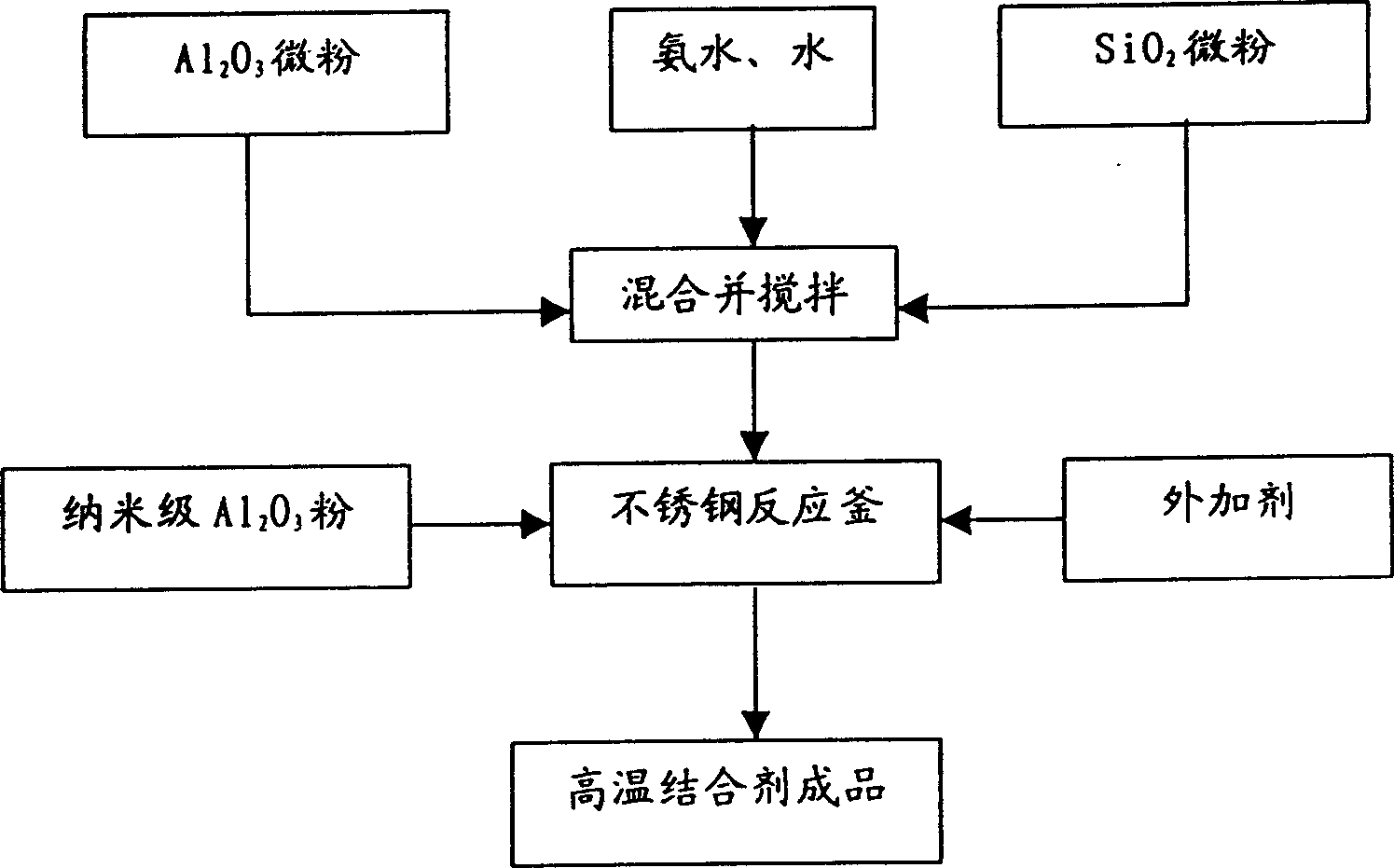

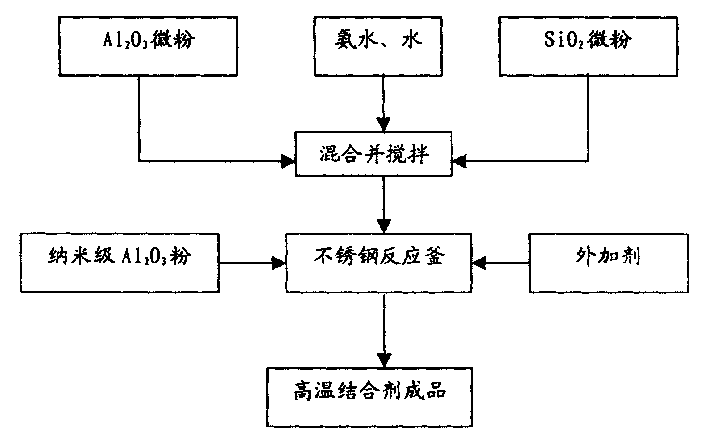

[0021] The preparation method of high temperature binder is as follows: figure 1 As shown, the proportion of Al 2 o 3 Micropowder, SiO 2 Micropowder, mix and stir evenly, add ammonia and water, put it into a stainless steel reaction kettle, and put nano-scale Al 2 o 3 Put the powder and admixture together into a stainless steel reaction kettle, and stir for 2 hours at a temperature of 110°C to make a finished high-temperature binder.

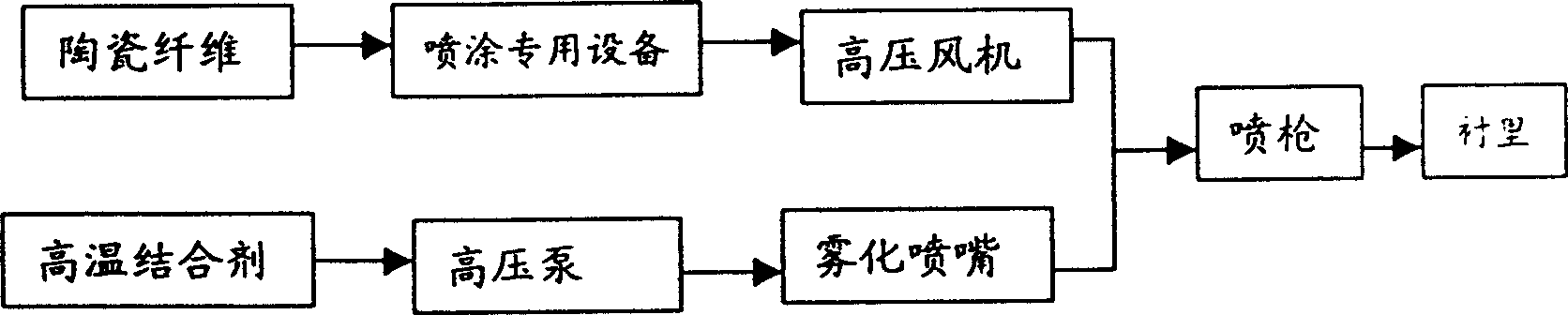

[0022] The construction technique of the dense type ceram...

Embodiment 2

[0025] Dense ceramic fiber spray lining composed of ceramic fiber and high temperature binder, the high temperature binder contains Al 2 o 3 Micropowder: 3.0%, SiO 2 Micropowder: 3.3%, nano-scale AlO 3 Powder: 0.9%, Ammonia: 1.1%, Nano ZrO 2 powder and nanoscale SiO 2 Powder: trace amount, additive: appropriate amount, water: the rest, the sum of the percentages of each component is 100%.

[0026] The preparation method of the high-temperature binder and the construction process of the dense ceramic fiber sprayed lining are the same as in the first embodiment.

Embodiment 3

[0028] High temperature bond contains Al 2 o 3 Micropowder: 3.2%, SiO 2 Micropowder: 3.5%, nanoscale Al 2 o 3 Powder: 0.9%, ammonia water: 1.1%, water: 91.3%, admixture: appropriate amount. The sum of the content percentages of each component is 100%.

[0029] The preparation method of the high-temperature binder and the construction process of the dense ceramic fiber sprayed lining are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com