Extraction of saponin from seeds of trigonella foenum-graecum

A technology of fenugreek and saponin, which is applied in the field of saponin extraction, can solve the problems of large solvent consumption and unsuitability for industrial production, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

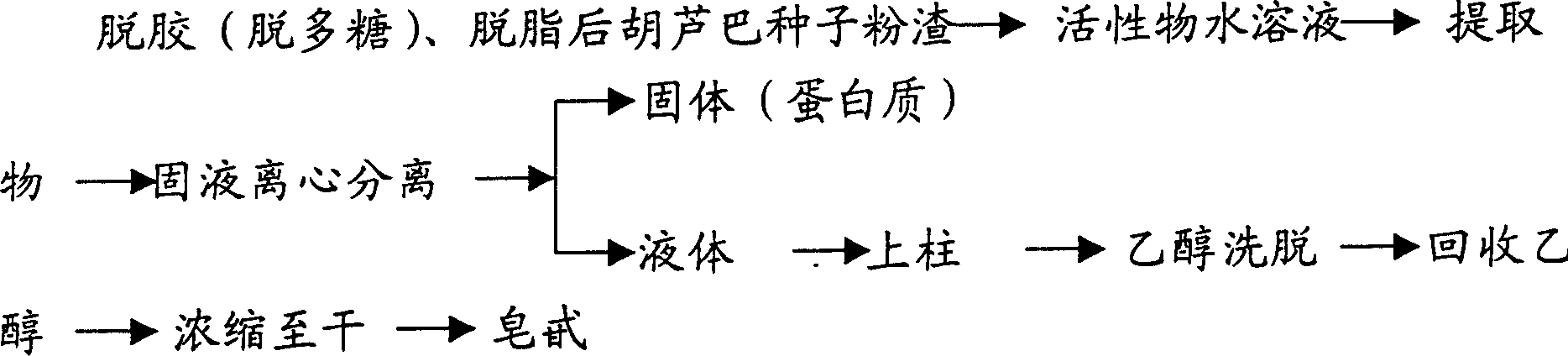

Method used

Image

Examples

Embodiment 1

[0017] Example 1: 1500g of degummed and degreased powder residue, add 6 times of water, add 22.5g each of mannase, amylase, and cellulase to the mixture, keep it warm at 45°C for 30 hours, and stir slowly (80 rpm) , after the completion of the reaction, centrifugal separation. The solid residue is protein. Put water on the column (type 101 large-pore resin column), wash with water, and elute with alcohol. After recovery of alcohol, 30.5 g of saponin crude product was obtained, and 17.5 g of pure product was obtained by methanol recrystallization once (MP152-155°C).

Embodiment 2

[0018] Embodiment 2: degumming, defatting fenugreek powder 1500g, add 6 times of water, add galactase, saccharification, cellulase, lipase each 30g in the mixture, at 50 ℃ for 28 hours, stir (100 rpm minutes), the reaction is completed, and the aqueous solution is centrifuged and put on the column (101 type large-pore resin column). Elute with ethanol, collect the ethanol solution, and recover the alcohol to obtain 41g of crude total saponins, and recrystallize once from methanol to obtain about 22.5g of pure product (MP: 152-155°C)

Embodiment 3

[0019] Example 3: 1500 g of degummed and degreased fenugreek powder, add 6 times of water, add 10 g of lipase and cellulase in the mixture, incubate at 50° C. for 30 hours, stir at 80 rpm, and after the reaction is completed, Centrifuge, put the water liquid on the column (101 type large-pore resin), wash with water, elute with alcohol, collect the eluent, recycle the alcohol, evaporate to dryness to obtain about 25g of crude saponin, and recrystallize with methanol to obtain 10.8g of pure saponin ( MP: 152-155°C).

[0020] The above-mentioned embodiment can obtain protein 400-500g when saponin is separated. Its content is 54-58%, which can be used in food and seasoning after hydrolysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com