Method of forming embolism and hole

A plug hole and spin-on glass technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as difficulty, high aspect ratio, and lower quality of metal lines, so as to reduce the difficulty and thickness of filling Effect of reducing and increasing process tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

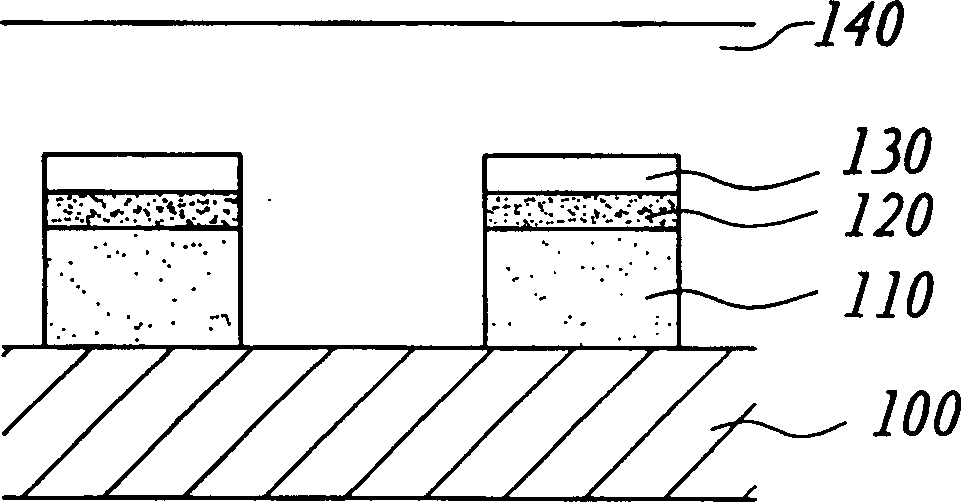

[0021] The present invention provides a kind of technological method that solves the hollow phenomenon in plugging hole etching, replaces traditional SiON layer with a spin-on-glass layer (SOG, spin on glass) or dyed spin-on-glass layer (dyed SOG), not only The un-landed phenomenon when etching the vias can be avoided, and the spin-on-glass layer or dye spin-on-glass layer also has the function of a hard mask layer, so the thickness of the photoresist layer can be reduced.

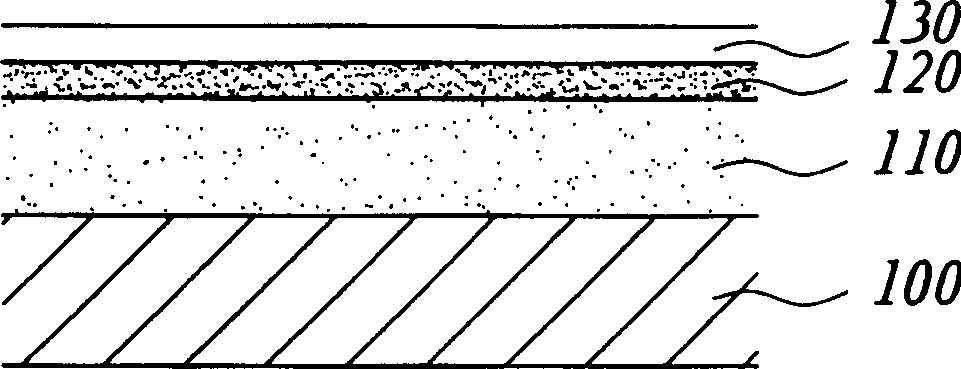

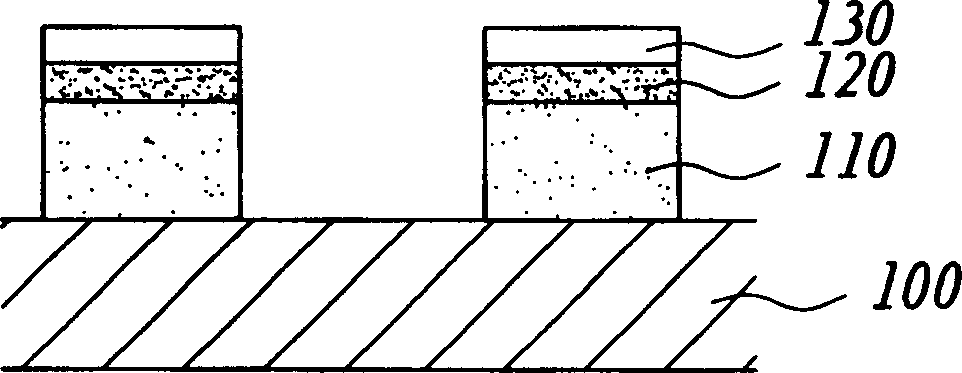

[0022] Figure 5 Shown is a cross-sectional view of a semiconductor showing the formation of metal stack layers according to the present invention. First, a substrate 500 is provided, and a metal layer 510 and an anti-oxidation reflective layer 520 are sequentially deposited on the substrate 500 by PVD deposition method, wherein the metal layer 510 is usually an aluminum layer, and the anti-oxidation reflective layer 520 is typically a TiN layer. Next, a spin-on-glass layer 535 is formed on the anti-oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com