High-frequency multiple-pulse ultrasonic emission driver and receiving circuit

A technology of transmitting drive and receiving circuit, which is applied in the field of high-frequency multi-pulse ultrasonic transmitting drive and pre-signal receiving circuit, which can solve the problems of poor instrument performance and precision, easy to be interfered, etc., and achieve good inhomogeneity and simple circuit Reliable, low-latency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

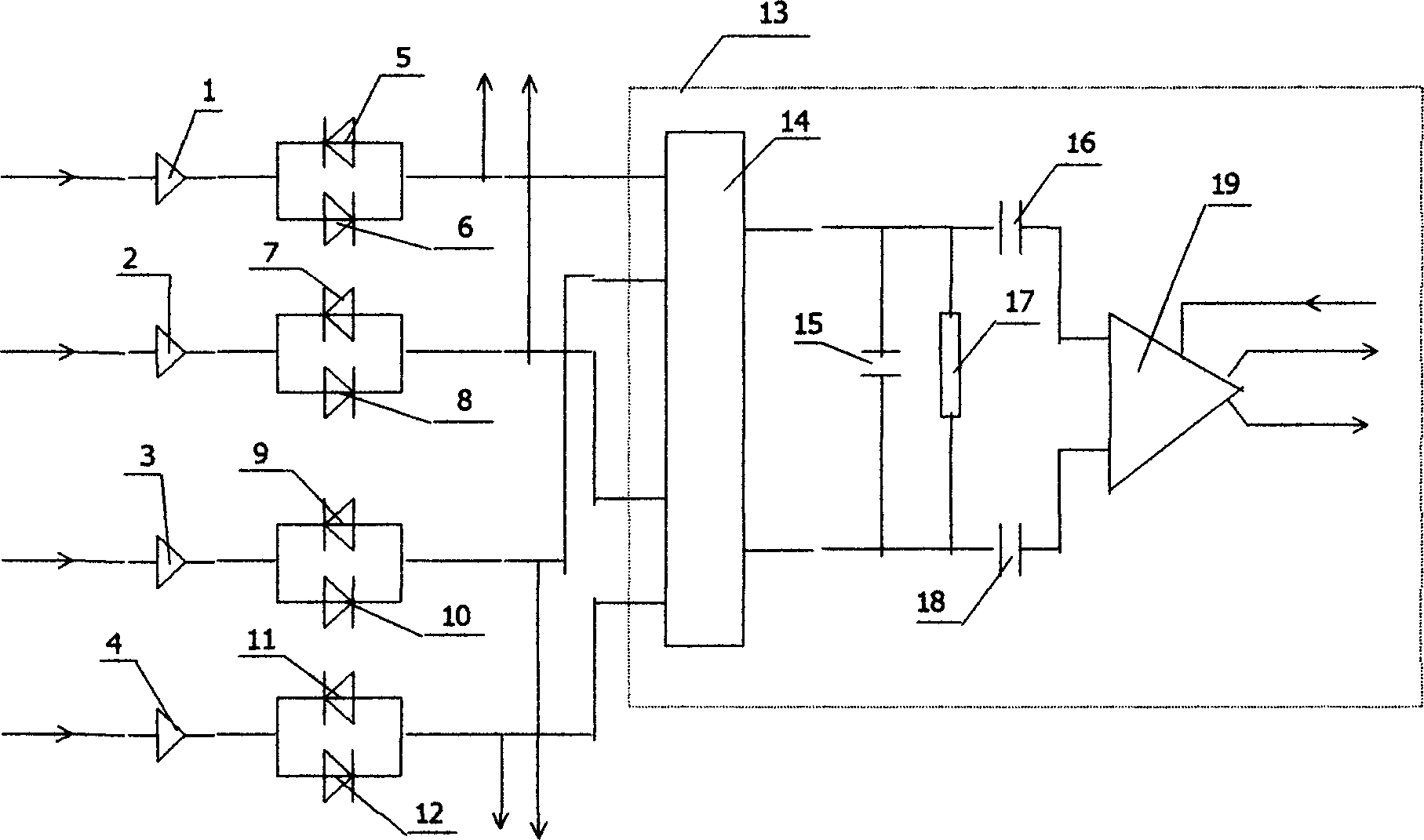

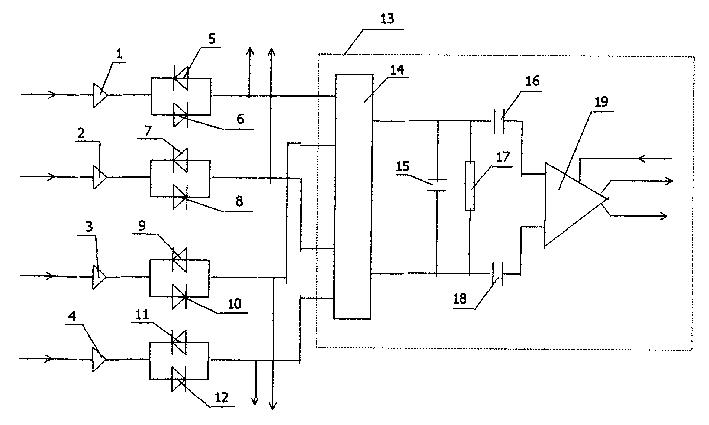

[0012] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

[0013] The current drivers 1, 2, 3, and 4 are TC4424 dual-channel MOSFET integrated drivers produced by the American MICROCHIP company, and the diodes 5, 6, 7, 8, 9, 10, 11, and 12 of the four groups of positive and negative diode pairs connected in parallel The conventional switching diode 1N4148 is selected, the integrated analog switch 14 is selected from the MAX4632 produced by MAXIM Company of the United States, and the automatic gain control amplifier 19 with dual balanced input uses the M1350 produced by Motorola. Capacitors 15, 16, 18 are 0.01uF, and resistor 17 is 1000 ohms.

[0014] The existing high-current MOSFET driver integrated circuit block is used to directly generate a large peak current drive signal, which is coupled to a piezoelectric ceramic chip through a switch diode with positive and negative poles connected in parallel for driving. The positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com