Process for producing a fluorinated alcohol

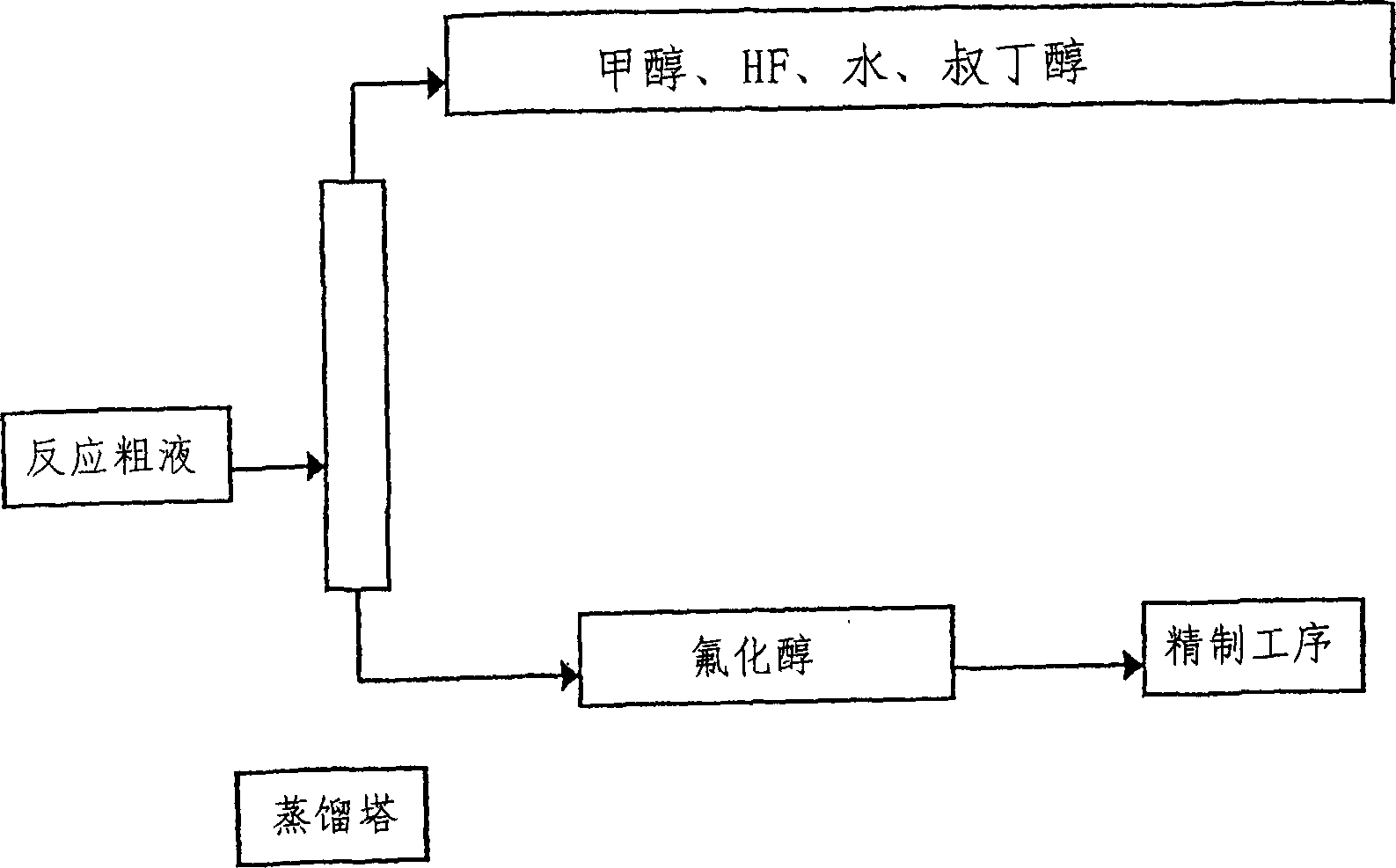

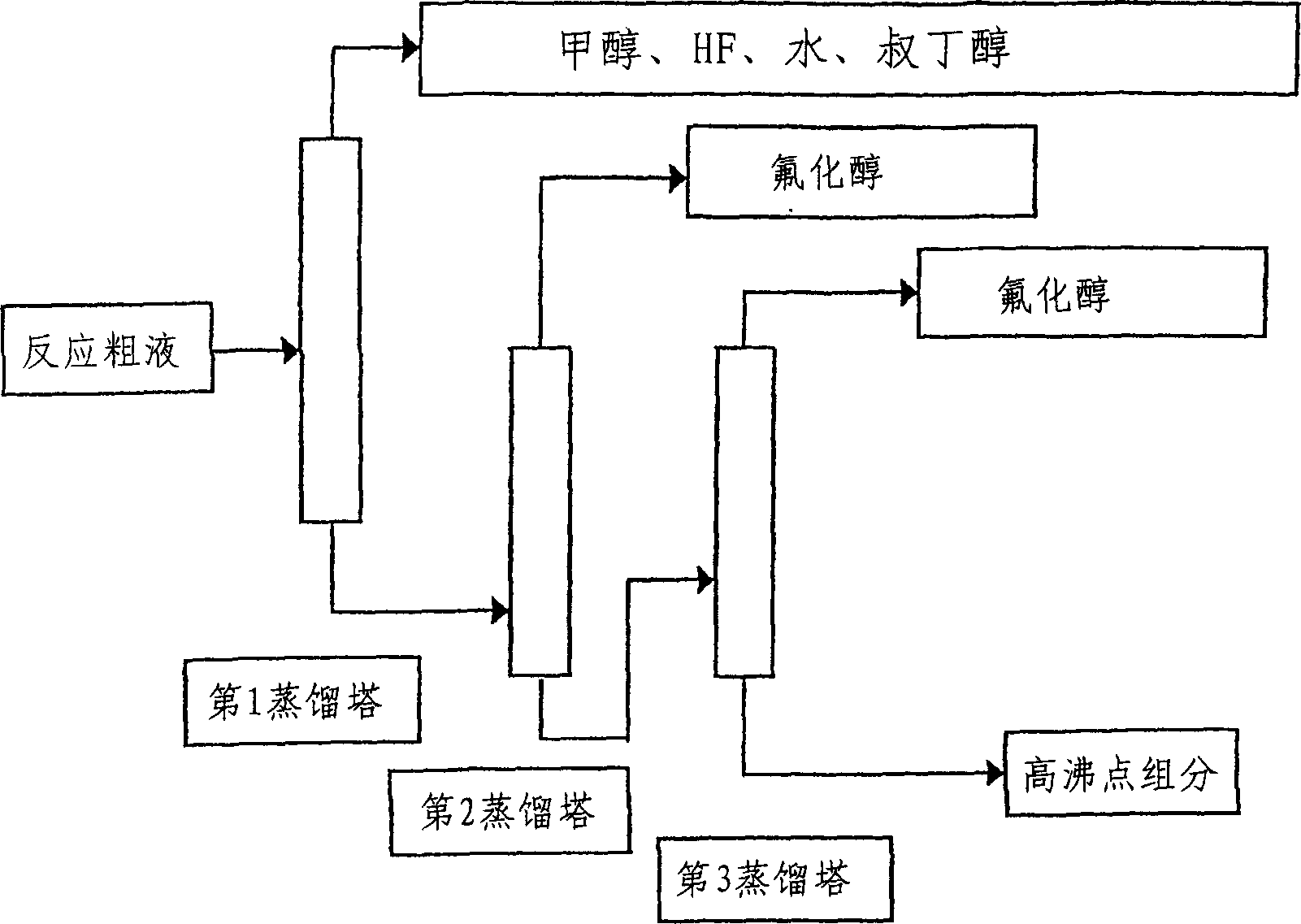

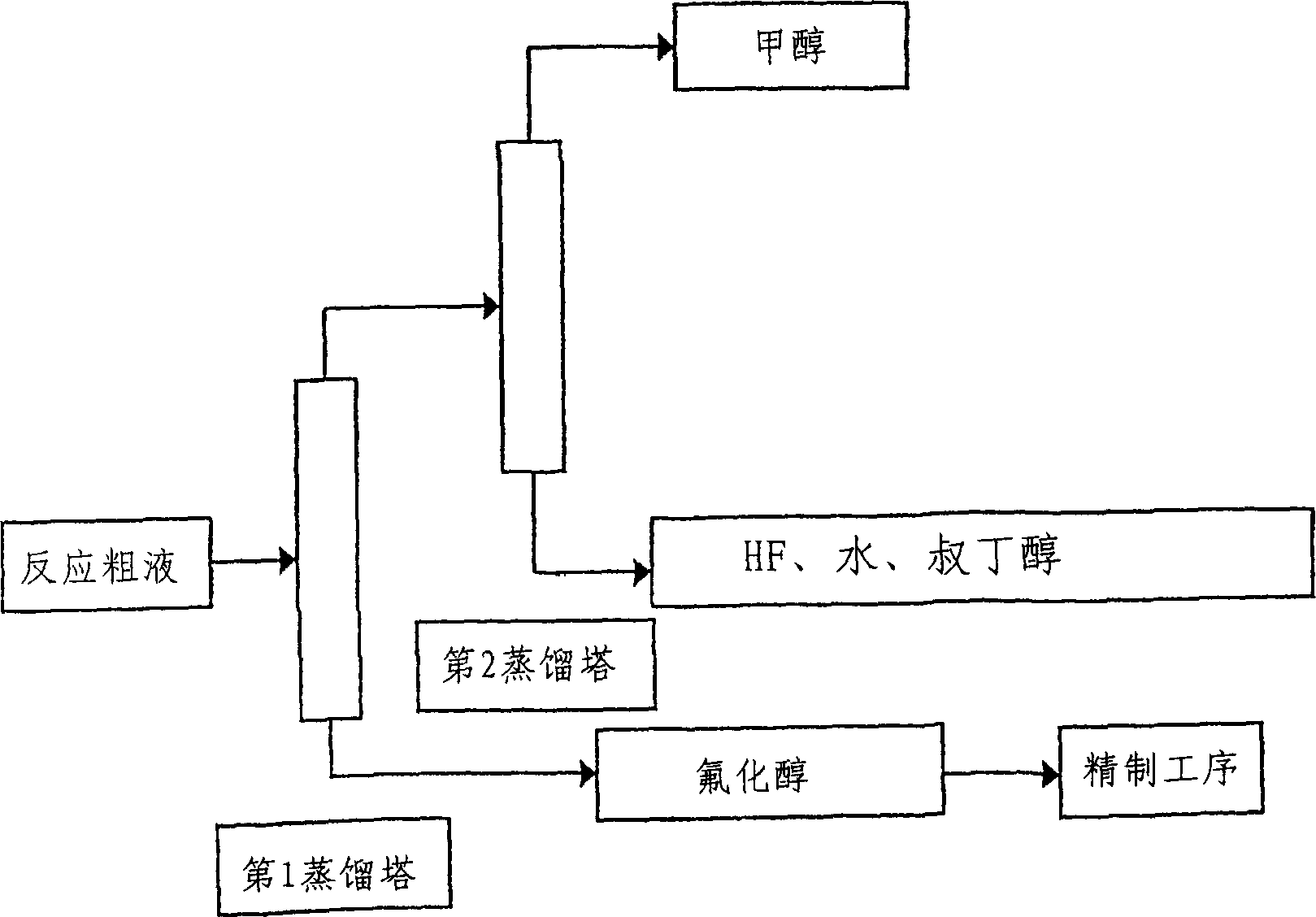

A technology for fluorinated alcohols and methanol, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of hydroxyl compounds, etc. It can solve the problems of low refining yield of fluorinated alcohols, low yield of fluorinated alcohols, heavy loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Hereinafter, the present invention will be explained in further detail with reference to examples. Hereinafter, the amount of water can be obtained by the Karl Fischer method; the amount of HF can be obtained by the fluoride ion electrode analysis method; the amount of organic compounds such as methanol, tert-butanol, and fluorinated alcohol can be analyzed by gas chromatography, and the Area % to calculate the respective proportions.

[0051] Example

[0052] Add methanol (3 cubic meters) and Perbutyl D (20 kilograms) alkyl peroxide to the autoclave with internal volume of 5 cubic meters, and flush the reaction kettle with nitrogen, then heat up to 125 ° C, and continuously add four Vinyl fluoride, making the internal pressure 0.8 MPa and reacting for 16 hours.

[0053] The reaction crude liquid after the reaction contained 100 ppm of unreacted Perbutyl D, 8000 ppm of t-butanol, 1500 ppm of HF, 3000 ppm of water and methanol as other components. Water was added to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com