Method for removing manganese in cast iron molten liquid and method for manufacturing nodular graphite cast iron

A manufacturing method and technology of ductile iron, applied in the field of manganese removal, can solve the problems of unclear Mn removal effect, increased production cost, complicated operation and management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0082] Using high-purity pig iron, electrolytic iron, and Fe-Mn alloy, a high-frequency electric furnace is used to smelt an intermediate alloy containing 0.35% by mass of Mn. Then, chemical analysis was performed to investigate the Mn content (mass %) in the master alloy (this Mn content is referred to as Mn1). Table 1 shows Mn and other chemical components (% by mass) of the master alloy.

[0083] master alloy

C

Si

mn

P

S

Mn0.35%

3.55

2.66

0.34

0.034

0.009

Mn0.7%

3.47

2.66

0.67

0.035

0.010

Mn1.5%

3.45

2.65

1.50

0.036

0.011

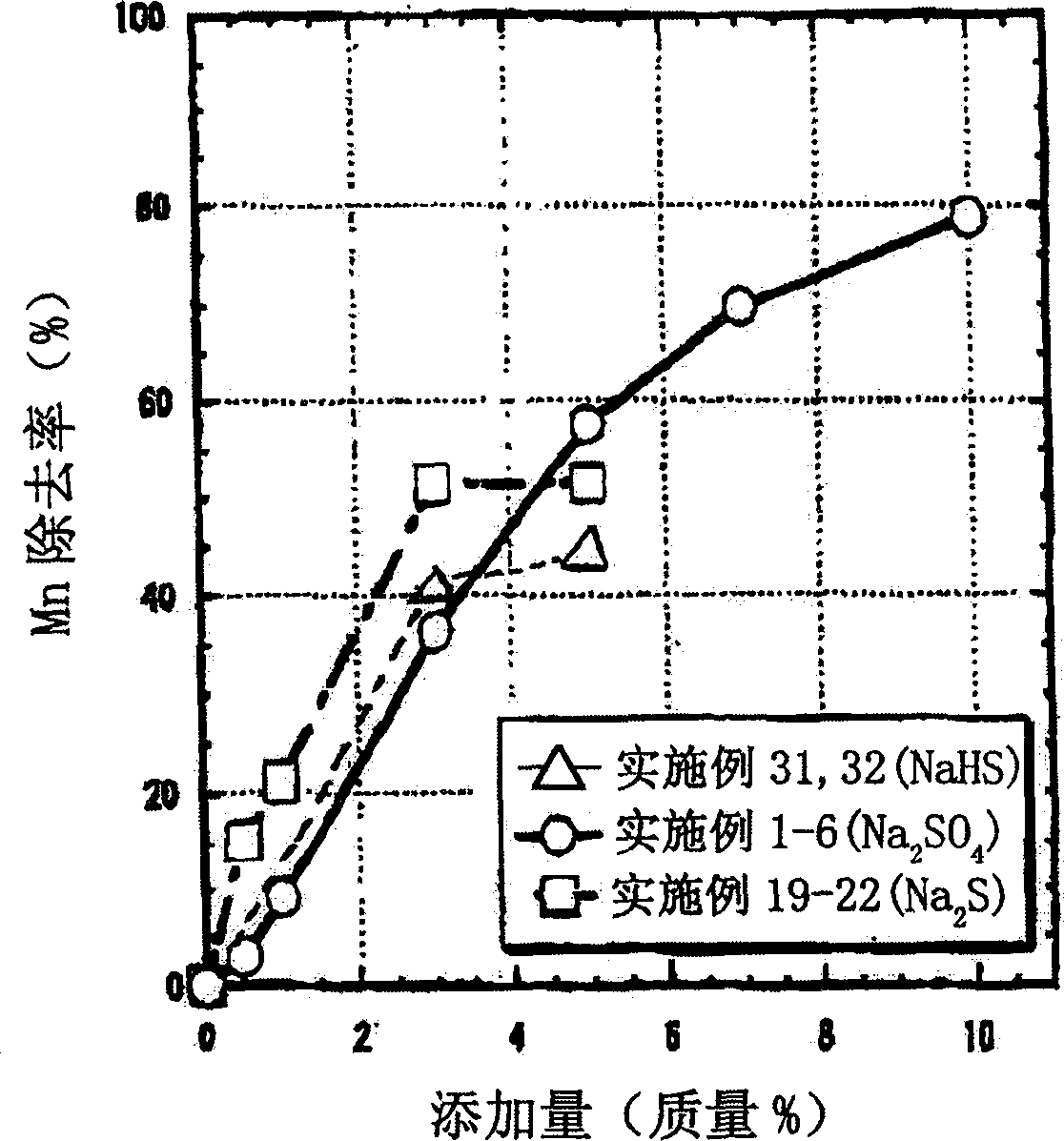

[0084] Next, 600 g of the master alloy was put into a graphite crucible with an inner diameter of 75 mmΦ×a height of 95 mm and melted in a high-frequency electric furnace. Then, while maintaining the temperature at 1400°C, add and mix Na 2 SO 4 As an additive, remove the slag after 5 minutes, ta...

Embodiment 7~12

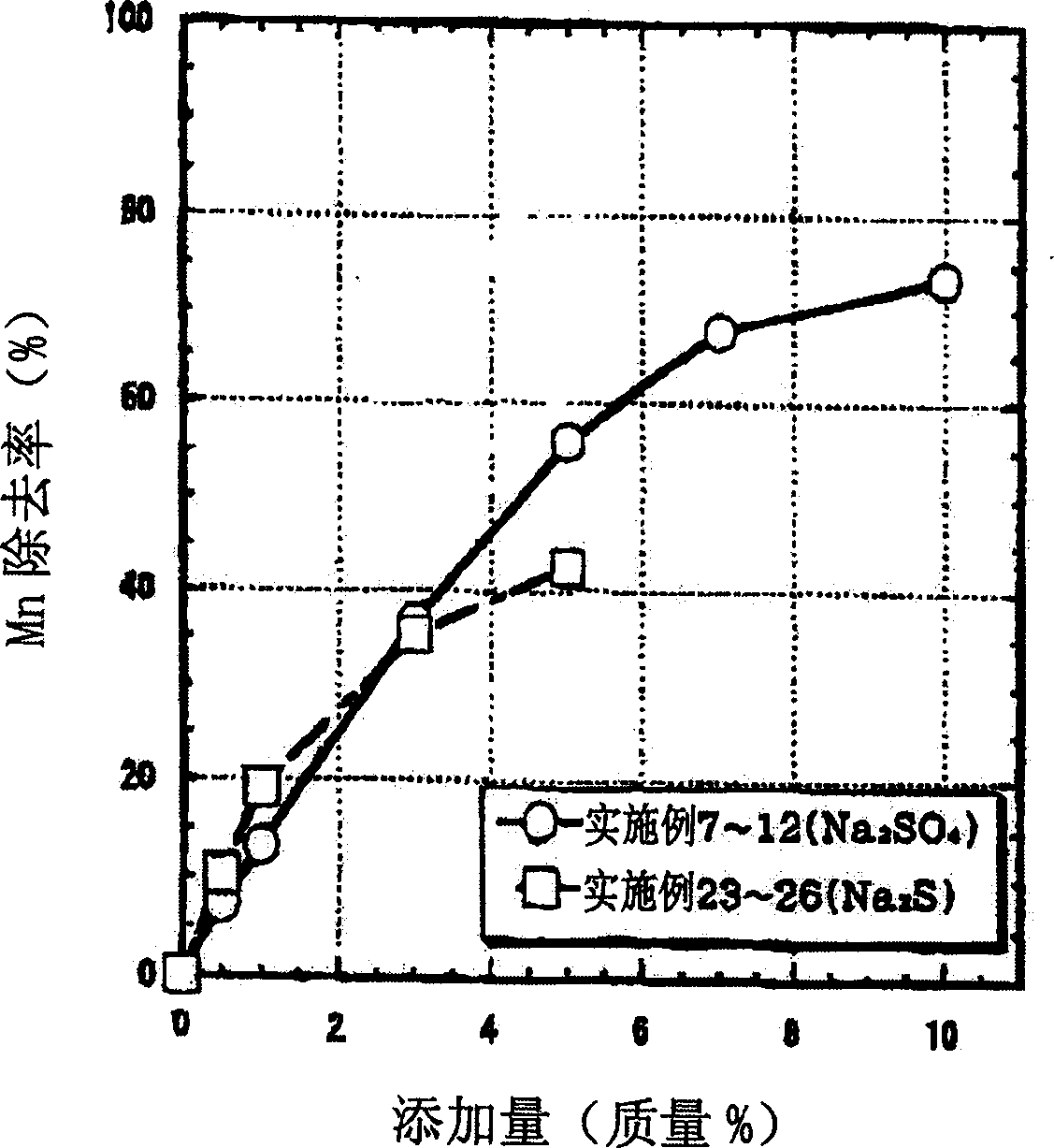

[0090] The Mn removal rate (%) was determined in the same manner as in Examples 1 to 6, except that a master alloy formulated to contain 0.7% by mass of Mn was used. Table 1 shows Mn and other chemical components (% by mass) of the master alloy. Na 2 SO 4 The addition amount is 0.5 mass % (embodiment 7), 1 mass % (embodiment 8), 3 mass % (embodiment 9), 5 mass % (embodiment 10), 7 mass % (embodiment 11), 10 mass % Mass % (Example 12). figure 2 shows the Na according to Examples 7-12 2 SO 4 The relationship between the amount of addition and the removal rate of Mn.

Embodiment 13~18

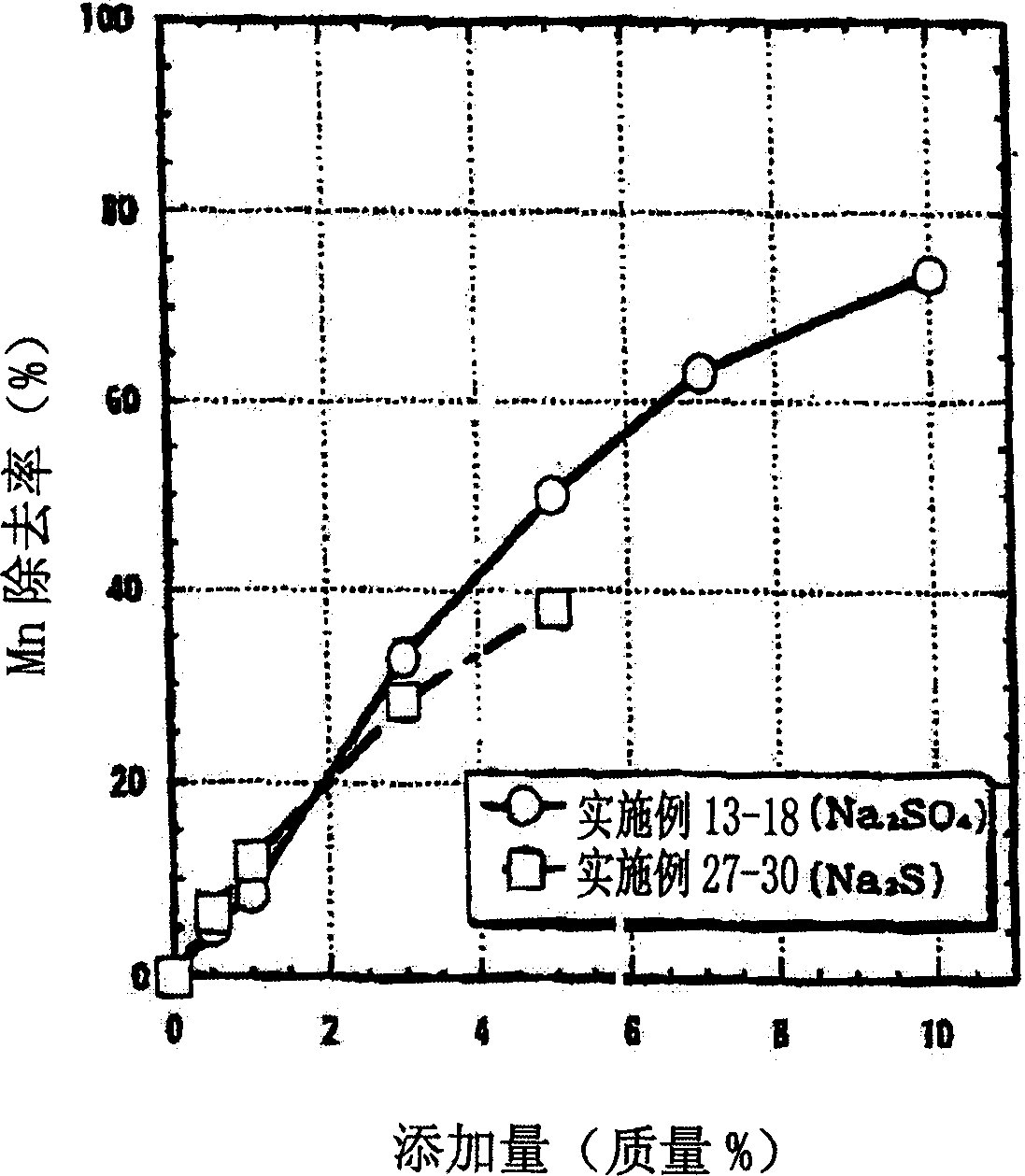

[0092] The Mn removal rate (%) was determined in the same manner as in Examples 1 to 6, except that a master alloy formulated to contain 1.5% by mass of Mn was used. Table 1 shows Mn and other chemical components (% by mass) of the master alloy. Na 2 SO 4 The addition amount is 0.5 mass % (embodiment 13), 1 mass % (embodiment 14), 3 mass % (embodiment 15), 5 mass % (embodiment 16), 7 mass % (embodiment 17), 10 mass % Mass % (Example 18). image 3 shows Na according to Examples 13-18 2 SO 4 The relationship between the amount of addition and the removal rate of Mn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com