One component thermose polyurethane system

A technology of heating and curing equipment, applied in the direction of coating, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

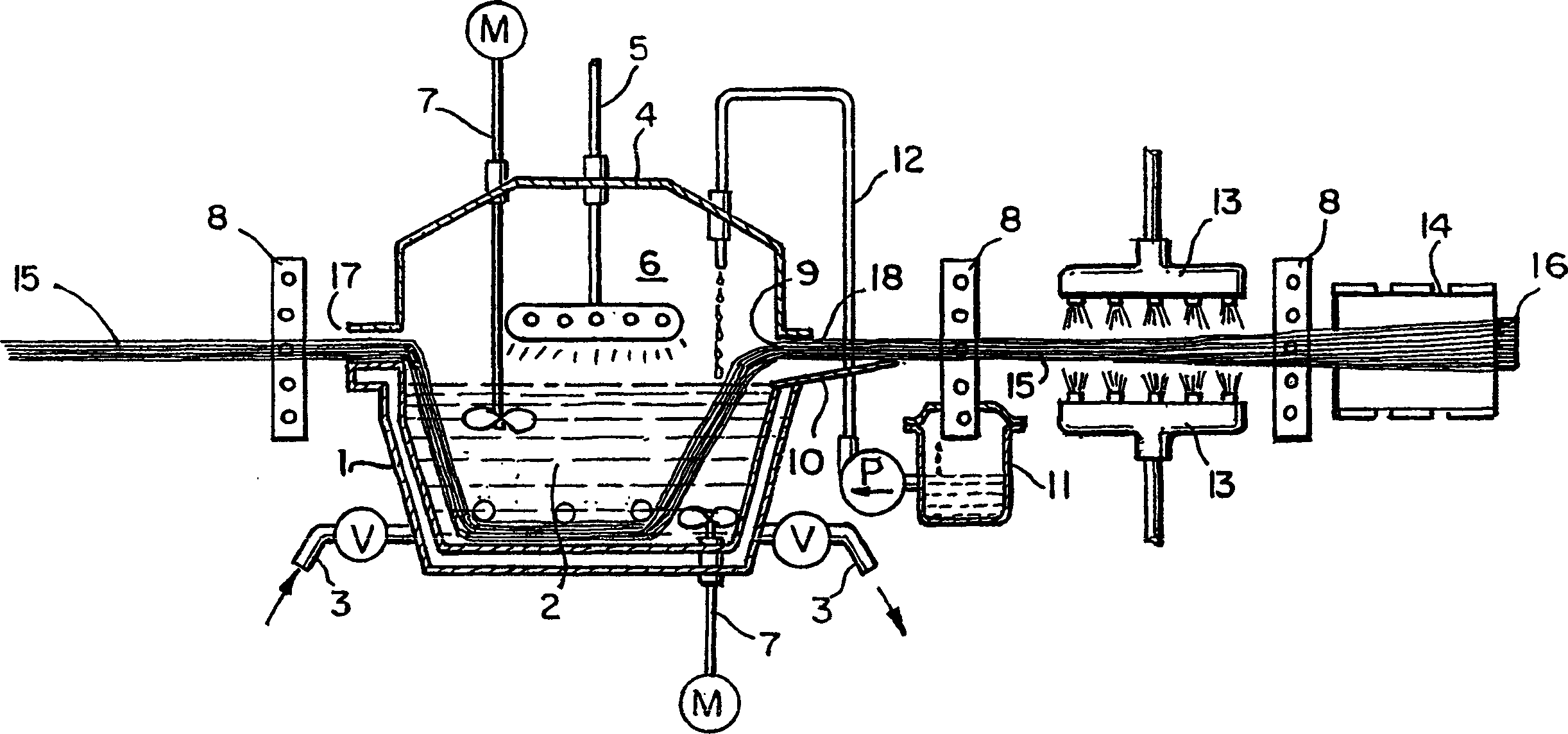

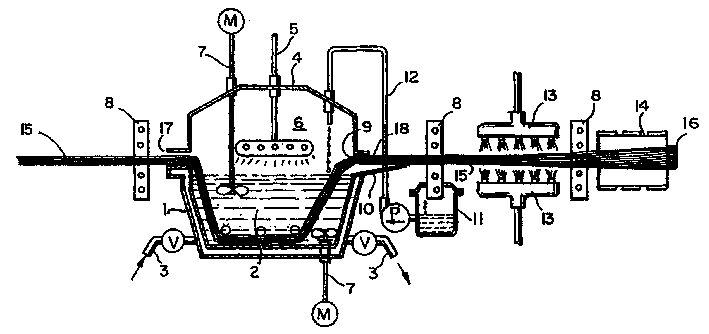

Image

Examples

Embodiment 1

[0104] This example illustrates the pultrusion of a glass fiber reinforced one component open bath polyisocyanurate system. The reactive components in an open bath are as follows:

[0105] reactive components Dosage (%)

[0106] RUBINATE 7304 44.640

[0107] SUPRASEC 2544 44.640

[0108] Motor Oil 10W30 05.360

[0109] LOXIOL G71S 05.360

[0110] total 100.00

[0111] The reaction mixture was kept at room temperature (25°C) during the experiment. Reinforcement material in the form of tapes and rovings (5 layers of two-way glass mat called 6-strand glass roving tape) was impregnated through the reaction mixture. The wet-out enhancing material is then passed through a series of outlets to remove excess impregnation reaction mixture. Excess reaction solution can be recycled back to the tank if collected under inert conditions (ie, free of moisture).

[0112] Using an airless spray gun (Wagner 1800 PSI 2 Step Pro Duty PowerPainter), apply D...

Embodiment 2

[0115] This example further illustrates the pultrusion of a glass fiber reinforced one-component open bath polyisocyanurate system. The reactive components in an open bath are as follows:

[0116] reactive components Dosage (%)

[0117] RUBINATE 7304 44.645

[0118] SUPRASEC 2544 44.645

[0119] Motor Oil 10W30 03.570

[0120] LOXIOL G71S 03.570

[0121] Munch / INT / 20A 03.570

[0122] total 100.00

[0123] The above components were prepared as in Example 1 to form an open bath. The temperature of the chemical mixture, glass geometry and pull rate were kept constant as in Example 1. In this example, the catalyst concentration was reduced to half of that in Example 1. 15 parts by weight of DABCO K-15 dissolved in 85 parts by weight of KEMESTER 5721-Motor oil-LOXIOL G71S (0.5:1:1 weight ratio) mixture. A 15% catalyst solution was obtained and used to spray onto the resin-impregnated glass reinforcement. Using the airless spray gu...

Embodiment 3

[0124] This example further illustrates the pultrusion of a glass fiber reinforced one-component open bath polyisocyanurate system. The reactive components in an open bath are as follows:

[0125] reactive components Dosage (%)

[0126] RUBINATE 7304 44.645

[0127] SUPRASEC 2544 44.645

[0128] Motor Oil 10W30 04.460

[0129] LOXIOL G71S 04.460

[0130] KEMESTER 5721 01.790

[0131] total 100.00

[0132] In this example, the catalyst concentration was reduced to 10%. 10 parts by weight of DABCO K-15 was dissolved in 90 parts by weight of a Munch / INT / 20A-motor oil (1:1 by weight) mixture. A 10% catalyst solution was thus obtained and used to spray onto the resin-impregnated glass reinforcement. Using the airless spray gun described in Example 1, the catalyst solution was sprayed at a rate of about 0.1-0.15 g solution / s. The temperature range of the curing die coupled by the forming die is 260-270°F. The cooling coil is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com