DC-DC converter having integrated magnetic cell and synchronous rectification

A technology of DC converter and synchronous rectification, which is applied in the direction of converting equipment with intermediate conversion to AC, DC power input conversion to DC power output, and output power conversion device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

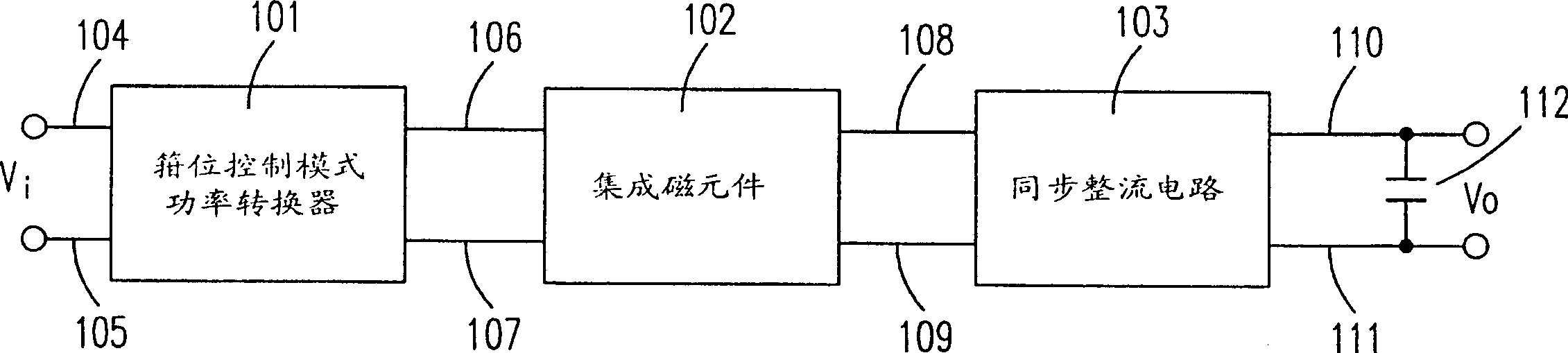

[0033] see figure 1 , figure 1 It is a circuit block diagram of the DC-DC converter with integrated magnetic components and synchronous rectification of the present invention. Such as figure 1 As shown, a DC voltage, such as 220 volts, is electrically connected to a clamp control mode power converter (power converter) 101 through two wires 104 , 105 . The DC voltage is switched to output a pulse wave signal, and the pulse wave signal is sent to an integrated magnetic element 102 through the wires 106 , 107 . The integrated magnetic element 102 converts the pulse signal to generate a low-voltage, high-current electrical signal, and transmits the low-voltage, high-current electrical signal to the synchronous rectification circuit 103 through the wires 108 and 109 . The electrical signal is rectified by the synchronous rectification circuit, output through the wires 110 , 111 and filtered by a filter capacitor 112 to provide a ripple-free DC output voltage. The integrated mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com