Surface active strong internal fixed titanium bone connection plate and its making method

A technology of surface activity and manufacturing method, which is applied in the direction of fixator, internal bone synthesis, external plate, etc., can solve the problems affecting the performance of internal fixation bone plate, poor wollastonite coating and osseointegration ability, etc., to achieve excellent Biological properties, easy industrial production, and easy-to-obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Alkali treatment-heat treatment two-step method to manufacture titanium substrate surface coverage can form TiO 2 gel porous TiO 2 internal fixation plate

[0059] (1) Alkali treatment

[0060] Soak the finely processed medical titanium bone plate matrix in NaOH solution with a temperature of 60°C and a concentration of 8 moles for 12 hours, so that the surface of the matrix will generate NaOH. 2 TiO 3 layer.

[0061] (2) Cleaning and drying

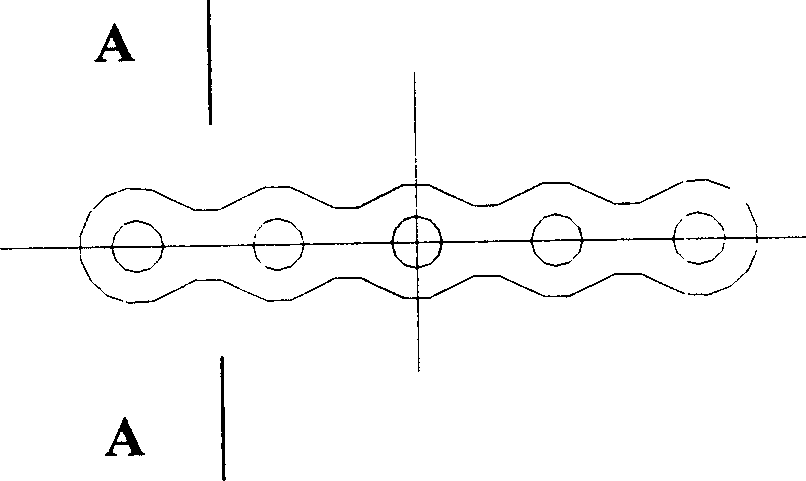

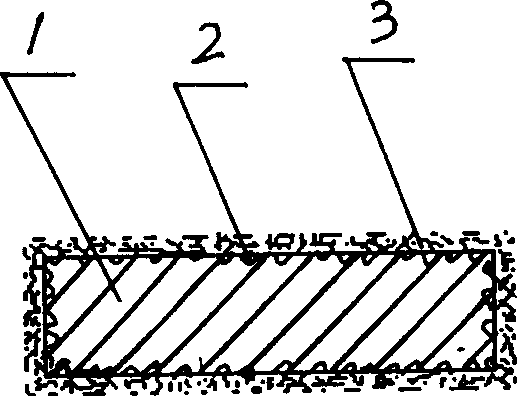

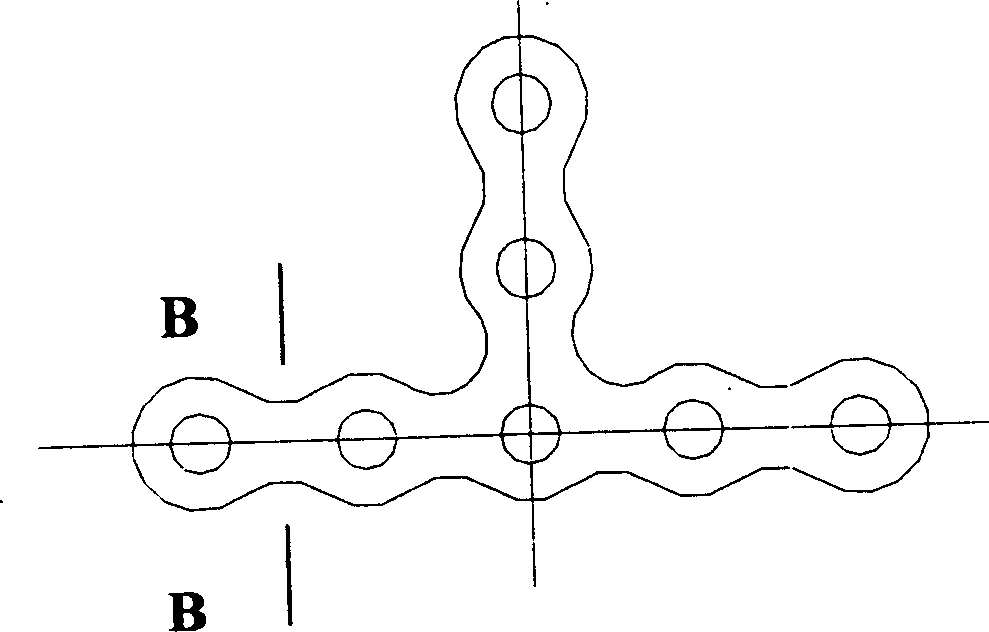

[0062] After alkali treatment, the surface is covered with Na 2 TiO 3 The layered titanium bone plate matrix is washed with distilled water and allowed to dry naturally, and a porous TiO layer with a thickness of about 6 microns can be formed on the surface of the titanium matrix 1. 2 Layer 3, such as figure 1 , figure 2 shown.

[0063] (3) heat treatment

[0064] Cover the dried surface with porous TiO 2 The layered titanium bone plate matrix is placed in a heat treatment device, and the temperature is...

Embodiment 2

[0065] Example 2: Acid-alkali two-step treatment method to manufacture titanium substrate surface covering can form TiO 2 gel porous TiO 2 internal fixation plate

[0066] (1) acid treatment

[0067] The treatment solution is prepared by 98% sulfuric acid, 36% hydrochloric acid and deionized water, sulfuric acid: hydrochloric acid: deionized water = 1:1:2, and the finished medical titanium bone plate base is treated at room temperature (20°C). 1 Soak in the above treatment solution for 60 minutes, then take it out and wash it with deionized water.

[0068] (2) Alkali treatment

[0069] Put the acid-treated titanium bone plate base 1 in a NaOH solution with a temperature of 150°C and a concentration of 0.2 moles and boil for 4 hours, then take it out and wash it with water, and after natural drying, a 5-micron-thick layer can be formed on the surface of the titanium base. Porous TiO 2 Layer 3, such as figure 1 , figure 2 shown.

Embodiment 3

[0070] Example 3: Manufacture of titanium alloy substrate surface coverage by anodic oxidation treatment can form TiO 2 gel porous TiO 2 internal fixation plate

[0071] (1) Anodizing treatment

[0072] The electrolyte is 1 molar H 2 SO 4 , at room temperature (20° C.), place the finished medical titanium alloy bone plate base 1 in an electrolysis device for anodic oxidation treatment, and pass a 150V direct current for 60 seconds.

[0073] (2) heat treatment

[0074] Put the titanium alloy bone plate substrate 1 after anodic oxidation treatment into the heat treatment equipment, carry out temperature program (such as 5°C / min) to 600°C and keep it warm for 60 minutes, then turn off the power and cool to room temperature with the furnace, and the titanium alloy substrate can be Porous TiO with a thickness of about 5 microns is formed on the surface 2 Layer 3, such as figure 1 , figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com