High-reflectivity high-damage threshold superwide-band fs laser reflector

A damage threshold, femtosecond laser technology, applied in the laser field, can solve the problems of easy damage to the coating layer, low damage threshold, and high requirements for coating machines, and achieve the effects of high anti-laser damage threshold, low laser absorption, and high light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

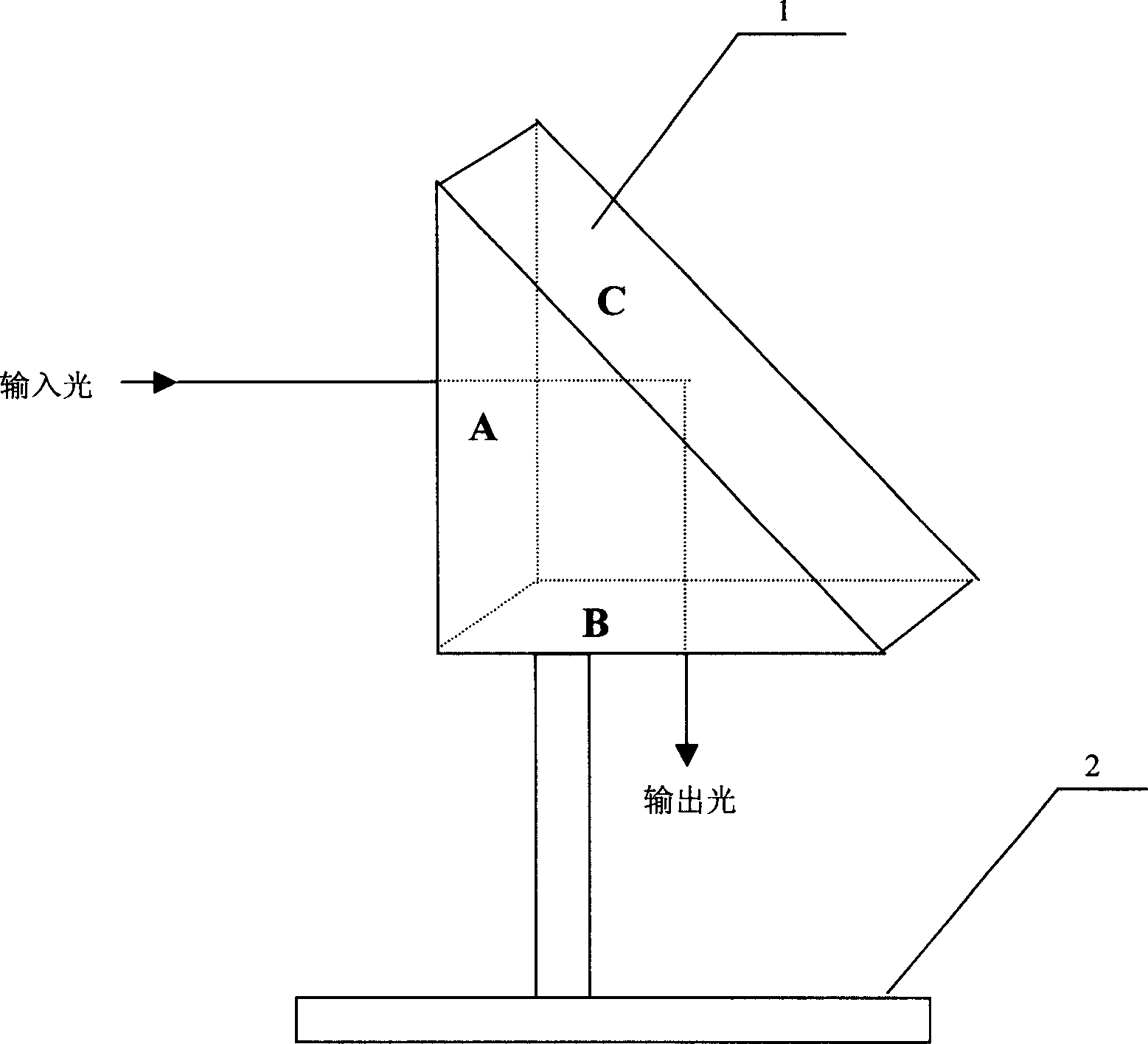

[0012] exist figure 1 Among them, the high reflection and high damage threshold ultra-broadband laser reflector of this embodiment is composed of a rectangular prism 1 and a bracket 2 connected together. The upper end of the bracket 2 is connected with the rectangular prism 1 through threads. The rectangular prism 1 of the present embodiment is an isosceles rectangular prism, the angle between the inclined plane C of the rectangular prism 1 and a right-angled side A is 45°, and the angle between the inclined plane C of the rectangular prism 1 and another right-angled side B is 45°, The material of the rectangular prism 1 is K9 optical glass. An anti-reflection film is coated on one right-angle side A of the right-angle prism 1, and an anti-reflection film is coated on the other right-angle side B of the right-angle prism 1. The material of the anti-reflection film is tantalum oxide and silicon oxide, vacuum alternately evaporated 8 layer, slope C is an optically polished sur...

Embodiment 2

[0014] In this embodiment, the right-angle prism 1 is made of K9 optical glass, and the anti-reflection coating vacuum-plated on one right-angle side A and the other right-angle side B of the right-angle prism 1 is tantalum oxide and silicon oxide, vacuum alternately evaporated layer 6. The geometric shape of the rectangular prism 1 and the connection relationship of other components are the same as those of the first embodiment.

Embodiment 3

[0016] In this embodiment, the right-angle prism 1 is made of K9 optical glass, and the anti-reflection coating vacuum-plated on one right-angle side A and the other right-angle side B of the right-angle prism 1 is tantalum oxide and silicon oxide, and vacuum alternately evaporates 12 layer. The geometric shape of the rectangular prism 1 and the connection relationship of other components are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com