Nanocomposite for fuel cell bipolar plate

A technology of fuel cells and conductive plates, applied in fuel cell components, nanotechnology for materials and surface science, fuel cells, etc., can solve problems such as amazing prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

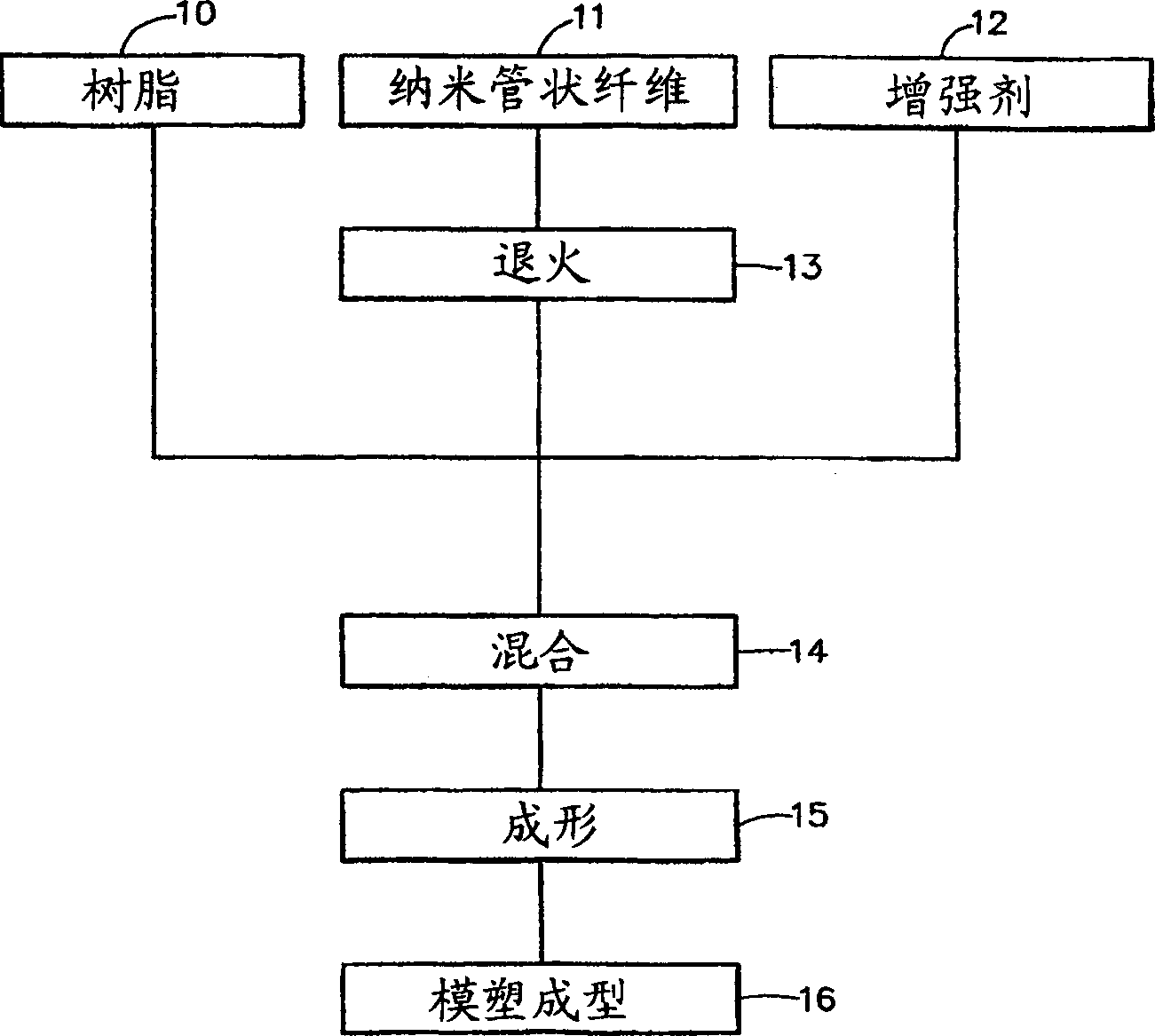

Method used

Image

Examples

Embodiment Construction

[0047] For the trademark PyrografIII produced by Applied Scienees Inc. TM The carbon nanotube-like fibers were sieved at 20 mesh and annealed at 2000° C. for 12 hours. Combine this fiber with Alcon TM Mix, Aclon TM The addition amount of this fiber is 25, 30, 40 and 45 wt.%. No other enhancers were added. The mixture was pelletized and pressure molded to form a 2 mm thick flow field plate. The above procedure was repeated, but annealed at 3000°C and the resin was a polypropylene copolymer ("PP") from Solvay Polymers under the trade mark Polypropylene TG7904. The added amount of fiber is 30wt% and 40wt%. The flow field plates are also made of graphite powder, and Aclon TM The addition amount of graphite is 70wt.%. The surface specific resistance through the plate was measured by a four-probe technique.

[0048] image 3 is a plot of specific resistance versus carbon loading for the above plates. The results showed that the electrical resistance was reduced by 1 / 2-1 / 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com